Metal parts are constantly required for machine repair. Well, if the model is common - you can buy. If the car is rare, you have to wait long for a long time will deliver, or order the manufacture. In this case, you can purchase a lathe for the garage. If you have experience, you can use it for a part time.

What types of turning machines are suitable for private use

Total turning machines are nine species, but not everything is needed in the garage. Most often, private traders can see small turning and rope machines. Along with the processing of parts (grinding, drilling, milling, drilling of radial holes, etc.) they are cutting the threads of different types and the sharpness of the cone. It is such a lathe for a garage that is trying to buy - it covers almost all the needs of car owners.

The lathe for the garage should not be too big

We are produced in two types - desktop and with bed (floor). Desktop are small, with a small weight (up to 200 kg) machines. For them in the garage it is easier to find a place. The disadvantage is big and heavy parts on them will not handle. Another point: due to a small mass, they are not always able to issue high processing accuracy.

Floor lathes (usually school) have significantly larger mass and dimensions. For normal operation, it is necessary to make a separate foundation. Installation is possible on vibrations, but they are not easy to find them.

Turning machine

In order to choose a lathe desirable to know its device, assignment, functions and possible parameters of each part. To begin with, we will analyze the main nodes.

- Base or bed. Preferably - heavy, cast cast iron stove. Even at desktop models. Very light machines will be unstable, because of what is even acceptable accuracy will be difficult to achieve.

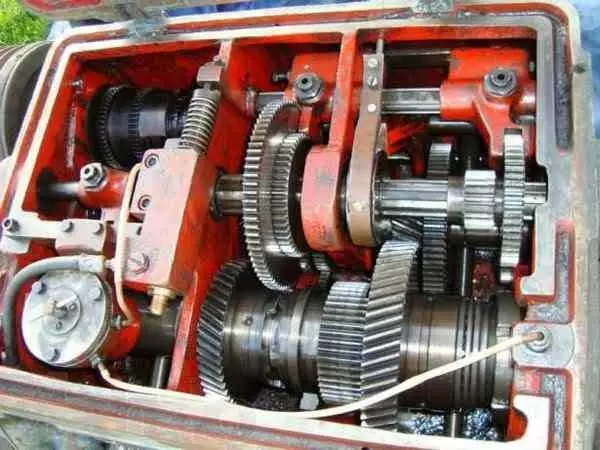

- Engine and gearbox. The engine can be powered by 220 V or from 380 V. Transmission - a device to ensure spindle and caliper (on automatic and semi-automatic machines). The machine will last longer if gear gears are made of metal (there are plastic).

- Front grandmother. The main function is a reliable fixation and rotation of the workpiece. This is usually a massive metal cylinder, rigidly fixed in the housing. Sometimes in the front headbox and gearbox are combined, in some models, the front grandmother can move the caliper or processing head.

Metal lathe device

- Rear grandmother. This part is also necessary for reliable fixation of parts relative to the spindle. When processing small parts, it is rarely used, more often - with long or massive. In some models on the backstone, additional equipment can be attached - cutter, drill, etc. - For the possibility of processing from two sides without changing the position of the part.

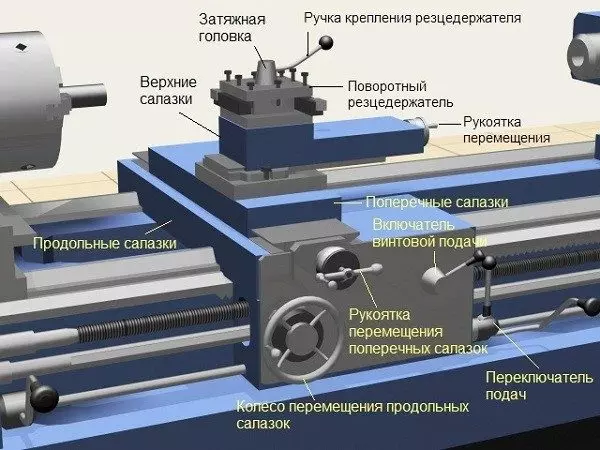

- Caliper. This is a node, from the device of which the list of operations performed by the machine. The caliper holds the cutting tool, shifting it when processing the part immediately in several planes (the simplest - only in the same plane). Can be controlled automatically or manually.

These are the main nodes of the lathe. It makes sense to consider complex nodes in more detail, since the possibilities and operation of equipment depend on their execution.

Stanina

Most often it is two parallel massive metal beams / walls, connected by crossing to give greater rigidity. The core and the rear grandmother moves along the bed. To do this, the guides of the Salazki are in advance. The rear grandmother moves on a flat guide, the caliper is prismatic. We rarely meet prismatic guides for the backstone.

Stanna for lathe for metal - factory and homemade

When choosing a used machine, pay attention to the state of the sled and the smoothness of the movement of parts on them.

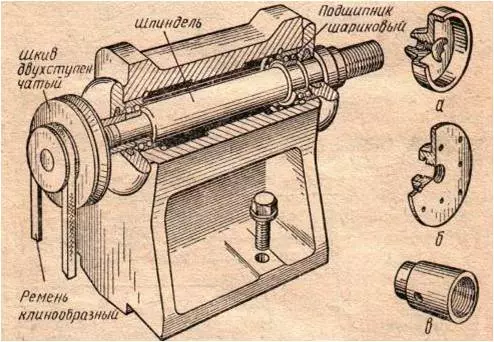

Front (spindle) grandma

The front headbox in modern lathes, most often, combines the partner of the part and the device for changing the spindle rotation speed. There are several types of rotation speed controls - using the levers transfer to a specific position using the regulator.

Front Grandma device

The control of the regulator with a smooth change of rotation speed is carried out on the basis of the microprocessor control. In this case, on the babik body there is a liquid crystal display on which the current speed is displayed.

The main part of the front grandmother - the spindle, which on one side connects with the plot of the electric drive, on the other, has a thread on which the cartridges that hold the processed part are checked. The accuracy of the execution of turning works directly depends on the state of the spindle. In this node there should be no beats and backlats.

Guitar gears - to transmit rotation and change its speed

In the front grandmother there is a replaceable gear system for transmitting and changing the rotation on the gear shaft. When you choose a lathe for a garage, pay attention to the state of the gear and the lack of spindle backlash. It depends on the accuracy of the processing of blanks.

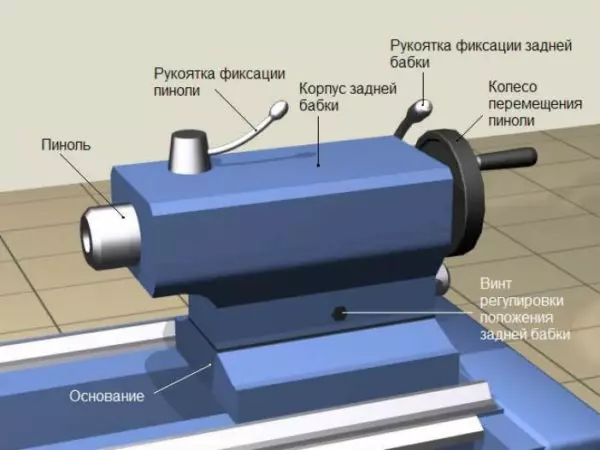

Rear grandmother

The rear grandmother is movable - moves along the guides on the bed. It is summed up to the part, its position is adjusted, the pinalty rests into the part, while holding it in the desired position, the position of the pin is fixed with the rotation of the corresponding handle. After that, the position of the back grandma is fixed by another locking handle.

In some models, the rear grandmother is designed not only to support massive or long details in a given direction, but also for their processing.

Device of the backstock lathe

To do this, on a pin, depending on the operations performed, the corresponding snap is fixed - the cutters, taps, drills. The extra center of the machine on the backstone can be fixed or rotating. The rotating rear center is made on high-speed machines, for removing large shavings, pulling the cones.

Caliper

Caliper lathes - a movable part on which tools for processing parts are attached. Thanks to the special design of this node, the cutter can move in three planes. The horizontal movement is provided by guides on the bed, longitudinal and transverse sled.

Caliper device

The position of the cutter relative to the surface of the machine (and the part) is set by the rotary massager. In each of the planes there is a retainer that provides hold in the specified position.

The cutter holder may be one or multi-seat. The sharply holder, most often, is made in the form of a cylinder with a side slot, which inserts a cutter fixed by bolts. On simple machines on the caliper there is a special groove in which the recess is inserted on the bottom of the holder. This is how the cutting tool is fixed on the machine.

Garage lathe: Parameters

First of all, we are determined with the mass and connection type. Choosing a lot, you should not strive to find the easiest machine. Very lungs do not give stability, can vibrate when working, which will affect the accuracy of work. Yes, heavy machines are established problematic, but the installation is a single event, it will have to work regularly. Therefore, the weight is far from the main criterion of choice.

Too large lathes are not in each garage can be installed, but small and medium - a great choice

Connection type is single-phase or three-phase - it is more important. And then, three-phase can be connected to 220 through special starters. From the electrical characteristics, the engine power is important. What it is higher than the greater rotation speed can develop the lathe. These are general moments. There are still special:

- The diameter of the workpiece that can be treated on the machine. Determined by the diameter of the processing over the bed and over the caliper.

- Long workpiece. Depends on the stroke.

- List of operations.

- Maximum revolutions.

- The adjustment method is smooth, stepped.

- The ability to reverse.

The dimensions of the processed parts are directly related to the size of the machine. So here you have to look for a reasonable compromise. Usually you do not want too clutching the garage, but you need to process overall parts.

Micro and mini lathes

In order not to clutch the garage, you can find mini or micro turning machines. They differ in very small sizes and a small mass. For example, a micro-lathe for a garage PROMA SM-250E has dimensions of 540 * 300 * 270 mm and a mass of 35 kg. Processing can be blanks with a length of 210 mm and a diameter of 140 mm. Smooth speed adjustment from 100 to 2000 rpm. For such sizes is not so bad.

Turning mini machines - in the garage they are the very place

Despite the small dimensions, the following operations can produce:

- scrapping surfaces

- cutting threads;

- drilling;

- cencing;

- deployment.

Possible grinding of parts, rolling, sharpening tool. The main operations seem to be present. The disadvantage is that on the machines of this type at least how many large parts do not process. And there is still a lack of specifically this model price. It is worth this lathe for a garage from $ 900.

In the same category, there are Chinese Jet BD-3 and JET BD-6 (price 500-600 $) and domestic Caton MML-01 (price of $ 900), Enkore Corvette 401 ($ 650), German Optimum - from $ 1300 to 6000 $; Czech PROMA - from $ 900,

Outdoor options

The choice is not so wide here, because both prices and lots are much higher. There are several proven models that can be installed in the garage.

Outdoor lathe for garage TV 4

These are the so-called school machines - TV 4 (its advanced version of TV 6), TV 7 and the desktop version of TV 16. With a mass of 280 kg (TV 4) and 400 kg of TV 7, it is desirable to preserve a separate foundation. If you put it just on the concrete floor, he breaks it.

Article on the topic: Polymer flooring for the floor: the order of the device