Sweet metal welding is a problem even for some welders with experience. The beginners in the welds are generally hard. There are not at all those rules that when welding thick products: there are many features and difficulties because of which it is harder to select modes and electrodes. It is easier to do this with welding semi-automatic, but they are in everyday life - a rather rare phenomenon, inverters are much more common. That's about the welding of thin metal inverter and will be discussed.

And the first complexity in the welding of the metal of a small thickness is that it is impossible to heat it and it is impossible: it burns, holes are formed. Therefore, they work according to the principle "The faster, the better" and any of what the trajectories of the movement of the electrodes are not in general. The thin metal metal is boiled by conducting an electrode in one direction - along the seam without any deviations.

When welding thin metal sheets overheat and bend

The second complexity is that it is necessary to work on small currents, and this leads to the fact that the arc has to do short. With insignificant detachment, she just goes out. Problems can also arise with arc ignition, because use devices with a good volt-ampere characteristic (idling voltage above 70 V) and smooth adjustment of the welded current, which starts from 10 A.

Another trouble: with a strong heating, a change in the geometry of thin sheets is changed: they are fused by waves. From this lack getting rid of very hard. The only option is to try not to overheat or take heat (about the method with heat sink gaskets read below).

When welding the jack of thin sheets of metal, their edges are carefully treated and cleaned. The presence of pollution and rust will make welding even more problematic. Therefore, thoroughly align and clean it. They have sheets very close one to the other - without a gap. Details are fixed by clamps, clamps and other devices. Then the details are grabbed every 7-10 cm short seams - patches. They will not allow the details to shift and their smaller probability will run.

Article on the topic: how to make a soldering iron with your own hands

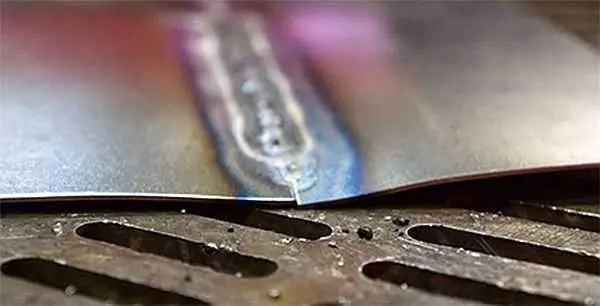

If it is well cleaned the edges, it may turn out good seam

How to cook thin metal inverter

Welding machines, outstanding constant current good in that we can cook on reverse polarity. To do this, connect the cable with the electrode holder, and "-" cling to the part. With such a connection, the electrode is greasy, and the metal warms up the minimum.

How to choose a welding inverter for home or cottages read here.

Cooking is necessary using the thinnest electrodes: from 1.5 mm to 2 mm. At the same time, you need to choose with a high melting coefficient: then even with small shots, it will be high-quality. The current is set small. For electrodes with a size of 1.5 mm, it should be about 30-45 amps, for "twos" - 40-60 amps. Really put sometimes below: It is important that you can work.

| Metal thickness, mm | 0.5 mm | 1.0 mm | 1.5 mm | 2.0 mm | 2.5 mm |

|---|---|---|---|---|---|

| Electrode diameter, mm | 1.0 mm | 1.6 mm - 2 mm | 2 mm | 2.0 mm - 2.5 mm | 3 mm |

| Current strength | 10-20 amperes | 30-35 ampers | 35-45 mm | 50-65 mm | 65-100 mm |

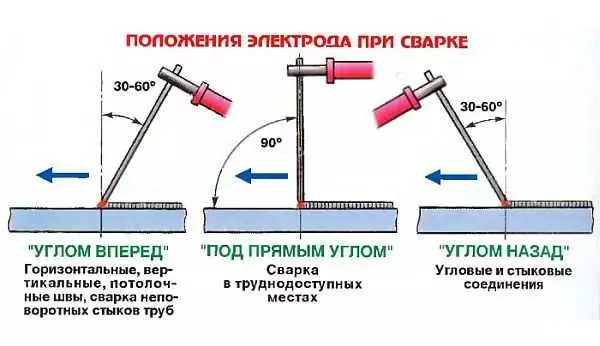

In order for the metal to be less heated, the details are put in the vertical or at least the inclined direction. Then boil over-down, moving the tip of the electrode strictly in this direction (without deflecting and not returning). The angle of inclination is an angle forward, while its value is 30-40 °. So the heating of the metal will be minimal, and this is for welding thin metals - one of the most important tasks.

Positions of the electrode during welding and their use

General recommendation for the choice of electrodes for welding thin metals: buy high-quality import electrodes for such a job. There will be less problems at times.

About the manufacture of a barn on a metal frame read here.

Techniques and methods for welding of thin sheets of metals

Sometimes thin sheets need to be welded at an angle. In this case, it is more convenient to use the folding method: the edges of the sheet are rejected to the desired angle, fasten with short transverse seams every 5-10 cm. After welding as mentioned above: continuous seam top-down.

The video shows how to cook a thin sheet metal with an electrode with a welding inverter. The method of flapping is used: the edges of the parts are rejected, then stick to short seams in several places. After there is a welding with a thin electrode with a thickness of 2 mm.

Article on the topic: Curtains for one side for the kitchen and bedrooms - the perfect solution

It is not always possible when welding without separation to avoid the burden. Then you can try to tear up the arc for a few moments, and then again omit the electrode to the same place and promote it for a few more millimeters. So, leaning and returning the arc, and cook. With this method, it turns out that the metal during the separation of the arc has time to cool. On the video you will see how the color of the welding location changes after the electrode has been removed. The main thing is not to give the metal to cool too much.

A thin metal welding with an arc separation is demonstrated in the first part of the video. The docking method is a mustache (one part overlaps the second by 1-3 cm), an electrode with a rutile coating (for structural and low alloy steels) is used. Then the stainless steel welding is shown by a stainless electrode with the main coating, and in the end of the same electrode from the stainless steel, the joint of the ferrous metal is suited. Seam, by the way, it turned out better than when using the recommended electrodes.

On the choice of electrodes for welding inverter apparatus, read here.

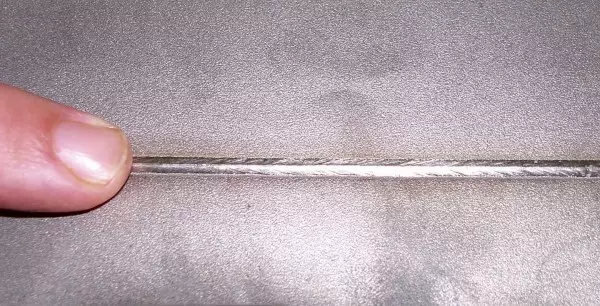

If during the welding of fine metal does not require the creation of a continuous seam, use point seams. With this method of welding a small size of the tape are at a short distance one near the other. This method is called intermittent seam.

It looks like intermittent seam on a thin metal

In general, boil the welding thin iron is difficult. Vangest is easier: the details are not overheated and less chances that everything will "behave."

Read about the types of welds and connections to read here.

When the electrical welding of a thin metal, the jack can be made between sheets of thin wire with a diameter of 2.5-3.5 mm (you can climb the coating on the damaged electrodes and use them). It is located so that it is in the face of it to be flushed with the surface of the metal, and with the invalid performed almost half a diameter. When welding the arc lead along this wire. It takes the main thermal load, and the weld metal sheets are heated by peripheral currents. At the same time, they do not overheat, they do not harvest, the seam is flat, without signs of overheating. After removing the wire, it is difficult to consider the traces of what she was present.

Article on the topic: Installation of plastic plinth on the ceiling with your own hands

So it looks like a seam when welding a thin metal jack with a lapped with a thermal wire

Another way is to put the plates of copper under the junction. Copper has a very high thermal conductivity - 7-8 times higher than that of steel. It laid under the welding. It takes a significant part of the heat, not allowing metal overheating. This method of welding thin metals is called "with heat sink linings."

How to cook a gazebo from metal. Read here. Perhaps you will be interested to read how to make a brand from a gas cylinder or metal? The thing is necessary and for the development of welding suitable.

Welding galvanovka

Galvanized steel is the same thin sheet, only covered with a layer of zinc. If you need to cook it, you will have to remove this coating on the edges for welding, to clean steel. There are several ways. The first is to remove mechanically: abrasive circle on the grinder or grinding, sandpaper and metal brushed. There is still a way - burn welding. In this case, twice pass the electrode pass along the seam. At the same time there is evaporation of zinc (it evaporates at 900 ° C), and its pairs are very poisonous. So you can spend these works either on the street, or if there is a hood in the workplace. After each pass, you need to shoot down flux.

Welding galvanized is better to carry out outdoors: evaporating zinc is very harmful

After complete removal of zinc, the welding itself begins. When welding galvanized pipes to obtain a good seam, there will be two passages with different electrodes. The first seam is boiled with rutile coating electrodes, for example, MP-3, ANO-4, OGSC-4. At the same time, the oscillations have a very small amplitude. Top seam - facing doing wider. It is approximately equal to the three diameters of the electrode. It is important not to rush and try to respond well. This passage is used by the electrodes with the main coating (for example, Woni-13/55, Woni-13/45, DSC-50).

Read more about choosing electrodes for inverter welding here.