Sometimes it happens that the normally working toilet appears chips or cracks, often they are sinning and tank, and bath shelves from ceramics, marble and so on. After all, even high-quality and expensive plumbing is used to crack and break, even despite the fairly good level of strength. But if the plumbing is dear, then it is simply not advisable to change it only because of a small misunderstanding.

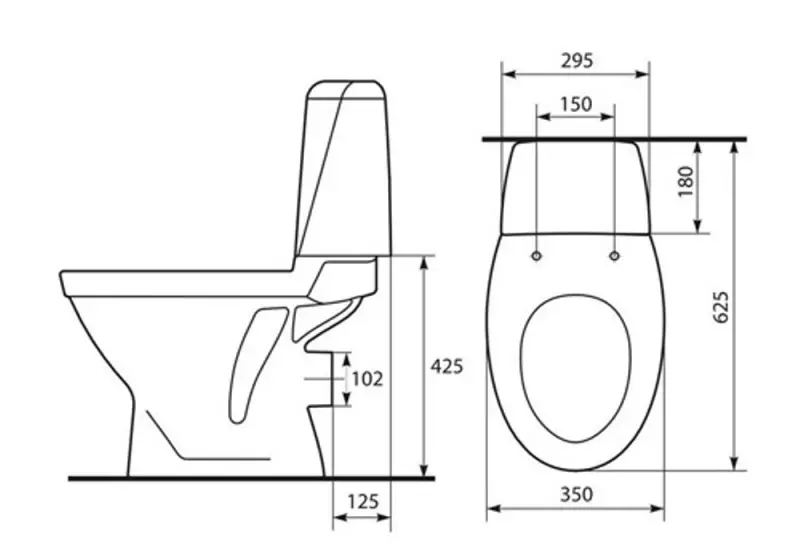

Drawing toilet bowl.

Let's talk about how and to glue the toilet, a tank, a shellf from a similar material. There is no possibility for all cases to say the exact time of possible exploitation of things after its repair: it is individually for each case and depends on the place of damage, from its size, the method of gluing and so on.

First bonding option

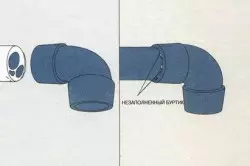

Steps to perform gluing sewer pipes.

In order to flick the crack or glue the chip toilet or a tank, you need to prepare the following:

- waterproof glue, cold welding, epoxy or silicone sealant;

- small skin grinding;

- acetone or solvent;

- narrow spatula for convenient application of gluing material;

- rag;

- Building hair dryer (can be home).

First of all, the chip and the damaged surface are carefully cleaned with a skin, a hairdryer or a rag, free from small particles. Then, both surfaces are degreased by a solvent or acetone and further warm the hairdryer in order to maximize moisture from the future seam area.

If a tank or toilet as a result of damage received not very large chick, then it will be more correctly glued with waterproof glue.

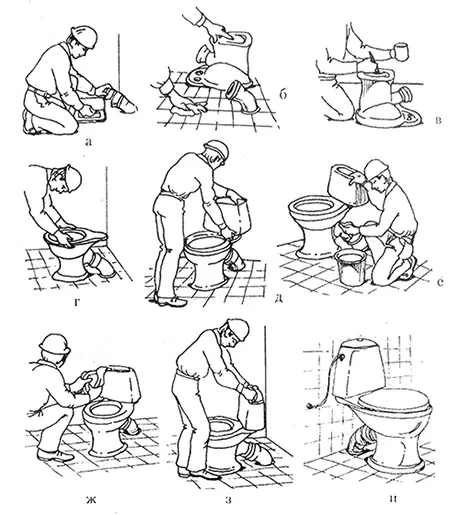

Toilet installation steps.

So, on a cleaned, degreased and well-dry surface, you need to very gently apply a thin layer of glue and according to the attached instructions to withstand the necessary time. Only after this pieces need to press each other as much as possible for a few minutes.

If you spend this stage correctly, it will be possible to forget about the chip for several years. But you should know that the damaged tank and the toilet, even if the place of the chip is not very noticeable or can not be visible, will require additional processing of the seam. First of all, to strengthen it, and in the second - for aesthetic purposes.

So, the outer seam obtained as a result of gluing a toilet bowl or a tank must be treated with the smelting of the seams used for ceramic tiles, or a special epoxy with a filler, maximally selected by the color of the sanitary equipment. The toilet or tank from the inside at the junction of the seams is enhanced by an additional layer of glue and a strip of soft stainless metal or thin plastic. Previous gain is purified by a grinding skirt, degreases and dried with a hairdryer.

Article on the topic: Monolithic concrete septic tank without pumping

Close the crack or toilet crack can be similar way. The inner and outer surfaces of the crack area are cleaned, degreased and thoroughly dried. The processed area is then thoroughly embarked in epoxy. And from the inside a tank or toilet on the site of the split is enhanced by gluing a strip of plastic or a soft stainless metal. On the outside, after drying epoxy glue, the crack area should be additionally missed by water-resistant glue.

General Gluing Rules for Plumbing

Preparation of pipes for gluing.

It is clear that in any case it is impossible to do without proper treatment of the connected surfaces, as described above. But one layer of glue is sometimes impossible to do, for example, if the surface on the fault has a complex relief.

In this case, careful sweeping with a grinding skirt can only damage: if some of the bulges are too sile, then voids may form when gluing, which will definitely not contribute to the safety strength. In this case, the result is only lightly, everything is being blown out with a hairdryer, degreases, sucked properly and drained with a thin layer of glue.

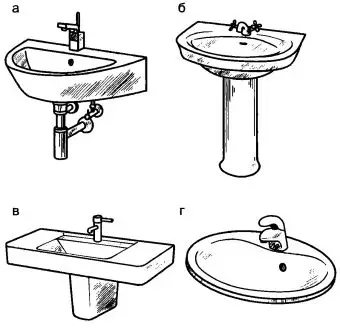

General view of the shells for the bathroom and toilet room: A - Console, B - on the pedestal, in - on the semophest, g - embedded.

Next, it is time to almost complete drying of the first layer of glue and only then the second is applied. And the second layer is withstanding according to the instructions, then the parts are glued. This is an important role that the force of pressed is played, and not the time. Ideally, it would be good to completely eliminate even microscopic air bubbles from the seam, so strong pressure and double layer of glue are so important.

If the tank got damage to the lid, then its split parts must be connected on the horizontal surface. And withstanding under the oppression require some adhesive compositions prepared on various solvents. When drying such glue, the solvent evaporates, and the surfaces of the glued surfaces occurs. To prevent a bad connection, use the oppression.

In order to securely fix the glued parts, they are usually used tight harness or clamp, and small ceramic items can be placed in a blank with clean sand, which puts the cargo, while the grains of the sand is transmitted to the uniform reinforcement.

Bonding marble surfaces

Some constructions of mixers: A - kitchen faucet, B - kitchen faucet with a shower grid, B - Washbasin faucet with controlled release.

For gluing marble plumbing (toilet shelf, mixer body, sink, tank) are used very different adhesives that require a certain application. Consider some adhesive compositions.

Article on the topic: On your own, we have a staircase staircase with tiles, porcelain stoneware

Universal and familiar to many universal glue BF-2 applies almost with any repair of plumbing. It is suitable for gluing plastic pipes, siphones, thermoplastics, fittings and other similar equipment, and for repair and gluing Sanatayans. And glueing glue BF-2 accelerates with the subsequent heating of the place of gluing.

It is for this purpose that the objects from the faience that cracked the mixers with a ceramic coating, the cover of the toilet tanks after gluing are heated above the electric stove or in the oven, heated to 100 ° C. Fayans and ceramics are quite reliably glued and finished adhesives: EPD, EPO, MC-1, Mars, Unicume, Rapid and the like.

Adhesive compositions of independent preparation

Sink device: 1 - wall mount; 2 - Bracket, 3 - Dumina, 4 - a wide nut, 5 - a shut-off nut, 6 - a glass, 7 - cement, 8 - sewage.

It is possible to make glue and do it yourself. For example, for gluing a ceramic or faience toilet bowl, you can prepare glue, which is based on casein.

Recipe first. 10 pieces of casein and 1 part of the drill are kneaded in 2 parts of the water, another 2 parts of the water are added later. To make a waterproof seam to the finished solution, add a few drops of solutions of aluminum alum or formalin. Such glue solidifies after 2-3 hours - during this time it should be used for its intended purpose.

In order to glue large porcelain or faience objects (toilet or a tank for example), you can prepare the following adhesive composition:

- 1 piece of crushed glass;

- 2 parts of river sainted sand;

- 6 pieces of liquid glass or silicate glue.

This glue is strong enough, but it is not very easy to make seams with him is unobthe.

Second recipe:

- 1 part of the oversized lime;

- 10 pieces of chalk;

- 2.5 pieces of liquid glass.

This composition should be prepared immediately before applying when the surfaces are fully prepared for gluing, as it quickly hards.

Recipe third. For the manufacture of the future, another composition of glue is suitable. For him, it is necessary to 1 part of the turpidar (by weight) and 2 parts of the light shellac. Skipidar and shellac melted on slow heat, mixed well and cooled. Next, the resulting mass can be divided into small tiles and leave for storage.

Such glue is stored long enough, it should be heated before use and apply a thin layer on the glued surfaces, which will then need to compress much. Speaking surplus glue is immediately removed.

Fourth recipe. Toilet bowls from porcelain or other items from this material can be glued on the basis of plaster. There will also be ordinary alums for the preparation of such adhesive. This adhesive is prepared as follows: in a saturated solution of alum, 24 hours are soaked in a burning gypsum, then it is dried, calcined and crushed, after the consistency is dusted with water.

Article on the topic: New Year's photo frame with your own hands

Bonding marble shell

Pipe gluing.

In order to manage to break the shell or a toilet from marble into several pieces, these items need to be at least dropping on a solid surface. But more often it turns out that there is a solid heavy item on them, in this case marble, although it does not split into parts, but small chips will be accurate. Sometimes cracks are obtained.

For the restoration of such items, Cashitz from a broken alabaster in adhesive water is used, which is suitable for white marble. And if necessary, add a broken slate, ocher or other fillers, to give a mixture of the required shade. After such a putty on the seams or cracks will freeze, it should be soldered.

Recipe fifth. Grinding gypsum in 4 pieces mix with 1 part of powder gumiarabic. To the resulting mixture is added to the state of the liquid test, a strong drill solution on cold water. The subject glued in this way is left for 5-7 days in a cool place.

If you need to make a seam almost inconspicuous, then the sealing toilet from marble or sink can be glued using a mixture based on the same marble, but is mounted in powder.

Recipe sixth. Mixed with rubber and waxed marble into powder in the following proportion: 2 parts of the marble powder are 2 parts of the wax and 1 part of the natural rubber. The mixture is heated in a water bath, then it is applied to glued, well-prepared surfaces, compress and remove excess glue.

Another recipe for the bonding of the faience and glass looks like this: 1 liter of water dissolves 100 g of hazed lime and 100 g of sugar. All this is boiled on slow heat for 3 hours without boiling. Then the mixture is defended and the water merges. 0.5 kg of chopped glue for tiles is added, the mass is stirred and maintained for half a day. The excess water with swollen glue merge, and it is put on a slow fire for complete dissolution. This glue is used in the chilled state.

This glue is still inferior to synthetic according to such parameters as water resistance and exposure to microorganisms. But for the absence of a synthetic adhesive composition, this will not be suitable for the opportunity to use more durable.

Of course, the list of synthetic and made self-made adhesives is not exhaustive. In our time, regular developments and innovations in specialized stores can also find other brands.