The valve is a pipe fittings. The classification of valves is quite diverse. But it will be about the wedge. Its design is designed to overlap the flow of the working medium in the pipeline. The wedge valve has a shutter, which, when performing actions aimed at opening or closing, is perpendicular to the flow of the working medium.

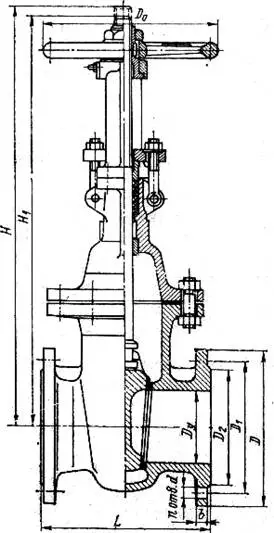

Scheme of self-adhesive wedge valves.

Its feature is directly shut-off element having a wedge form. The shutter shut-off parts are escranted towards the end and close the gate saddle, located at an angle relative to each other.

The functions of the wedge valves are as follows. This is a category of shut-off reinforcement, which has a complete overlap of the flow of the working medium. The wedge gate has only two main positions: open and closed.

How does a cloth valve act?

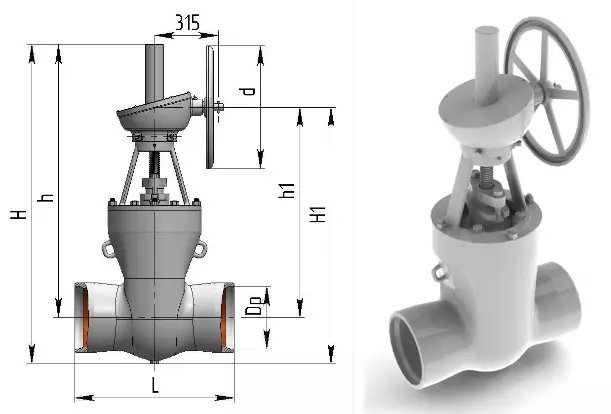

Steel blade valve with retractable spindle.

In the valve there is a special saddle (hole), it is through it that the working environment has the ability to move. The shutter in the design of a wedge valve - the element is movable. He can rise and descend.

If the shutter is raised up, then the seat (holes) on both sides have the position "openly". This position allows the working environment to flow freely through the valve and further along the fittings into the general system. If the wedge is in a lowered position, the seat holes overlap, which means that the movement of the working medium stops.

How does the wedge shutter be raised?

It rises as a result of hoisting on the spindle. This is a piece of thread gate, the shutter is attached to it using a nut. At that moment when the spindle performs the movements of the rotational character or rotationally progressive, the wedge rises with it. In turn, the spindle rotation is carried out due to the movement of the handle (if it is manual control) or an electrical drive.

Classification of wizard valves

Latch scheme.The classification of wedge valves implies their separation on narrowed and full-way.

Full-parties have a diametrical hole size of the rings (sealing) equal to the diameter of the pipeline hole. If we are talking about a narrowed version, then the diameter is less than the hole in the pipeline system.

Article on the topic: How to make a mosaic from a bat tile - step-by-step instruction

Another classification is possible in accordance with the nature of the spindle movement (rod). In this case, the wedge valves can be with a retractable or non-adjustable spindle. If the rod stretching, then when opening the valve, its height increases (construction), the spindle itself performs the movement of a screw character. The unlikely spindle allows the valve not to change its construction height. The movement of the rod in this case is rotational.

As for the design of the shutters, they can also be different. For example, an ordinary wedge gate can have either a rigid shutter or elastic or two-disc. And now in more detail.

Hard character wedge - whole one. Its design allows a sufficiently thick fit to the holes of the saddle. But in this case, there is a difficulty of adjusting to saddles and the possibility of jamming appears. This, of course, minus such a variety of wedge.

The second version of the wedge in the valve is dual-disc. This is a design of fixed drives located at an angle. Such a location and forms a wedge.

But the elastic wedges basically also consists of two disks, but its difference is expressed in a moving connection. This is the most sealed variant of the valve, since when it is used, it provides a very dense fit of the wedge shutter to the holes of the saddle. And one more plus of this type: such valves break significantly less often.

Preferential characteristics of a wedge valve

The first thing I want to mention as a significant plus is a simple design of a wedge valve (CCL). But that's not all. Hydraulic resistance in such a type of valves is rather weak, and, of course, it is impossible not to say about a small construction height.

Now about minuses. Here you can safely indicate the need to use much effort to fulfill the full opening or overlapping of the working body. Well, the building height, if compared with valves, is much larger.

Reliability of wedge valves during operation directly depends on the proper selection of the design and compliance with the necessary characteristics.

Article on the topic: inexpensive fence for giving. What is cheaper to make a fence?

How to repair valve wedge correctly?

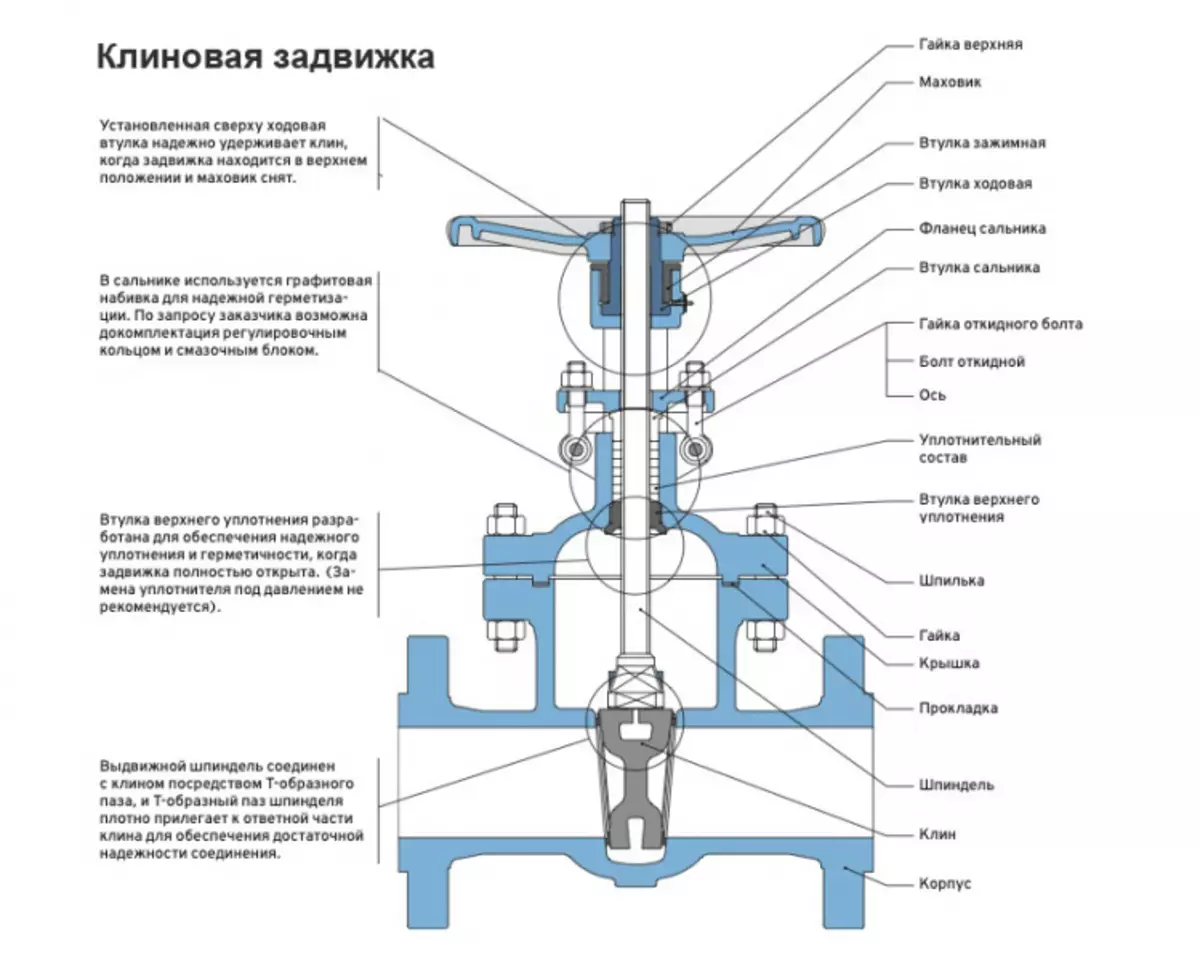

Scheme of a wedge valve.

The fact that the wedge valves need regular maintenance, of course, adds a number of inconvenience in the operation process. But the fact that the repair of a wedge valve is possible, speaks of its advantages over other species. Repair technology is different depending on the current situation. Consider some of the most common faults under which the repair is possible.

It happens that using a wedge valve, we pay attention to the insufficient tightness of the working medium flow overlap. What can contribute to this?

Such a problem may occur as a result of possible defects of the housing and shutter surfaces. These can be various sediments or damage, for example, scale or scratches. What to do in this situation, what repair is done?

To achieve good tightness, it is necessary to carry out the ticking of the sealing surfaces.

This applies to the shutter and hull. Most often their surface is made of bronze. First you need to disassemble the lid lid, pull out the shutter (body) and grinding. You can use a variety of diamond pastes. The graininess should have a gradual transition from larger to small.

The problem of another kind when the liquid flows through the stem from under the gland. Here, most likely, the rod is not complicated enough. Repair will be as follows. To fix the situation, you need to pull the glands, and if you need, it is possible to replace their packing at all. If, as a result of the replacement of the gland, the flow remains still, it can be in stock. It means that corrosion sinks could form in it. If so, then avoid its replacement is unlikely to succeed.

The impossibility of turning the flywheel. Here everything is simple enough: the shutter jammed. This situation takes place in those valves that are irregularly subjected to maintenance and whose discovery is likely to be produced no more than once a year.

As a result of such operation, the sealing surfaces are formed on the sealing surfaces.

Technology of this repair is as follows.

Article on the topic: Linen curtains: Recommendations for the selection and operation

To eliminate this problem, the top lid of the valve is removed, the sealing elements are cleaned. If necessary, the trigger of contact surfaces is performed. In no case do not knock on the spindle (stock), since such actions are likely to lead to the fact that the guide nut will be torn.

Another frequent problem: the rotation of the flywheel is possible, but the discovery of the valve does not occur. This speaks about the shutter break. Retractable spindle valves are the object of this fault.

This means that the "cam" stem was worn out, which should hold the shutter, or broke the carving on the nut, which directs the rod. Repair will include the following steps. In the last embodiment, the displaced "cam" is carried out. Another repairs is toggle it. Nut is also subject to replacement, if, of course, the design of the valve allows you to do.

If your valve has an unlikely spindle, then the shutter falling occurs when erasing the nut with fixation in it. To eliminate this malfunction, you need to replace the shutter.

Do not forget that all the actions on the disassembly of the valve, if it is under pressure, is strictly prohibited.

After the installation is completed, air is removed from the valve. To do this, you need to easily attenu bolts that pressed the gland. After the water drops appear under the gland, you can press the bolts.

Operating and maintenance tips

Performing repair of such systems, requires tools:

- Passatia;

- screwdriver;

- knife;

- file.

It is very important at least once a month to produce a full cycle of opening and closing the valve. This is necessary to clean the contacting (rubbed) surfaces from the accumulation of scale and sludge.

Do not forget that the valve rod having a retractable spindle should always be in a lubricated state.

Once a week check on the tightness of the sulpage sealing stock. If it is necessary, you need to replace it or the suspender. If the pipeline is under pressure, the replacement of the gland is unacceptable.

And also, during operation, the gate valve must be only in the "open" or "closed" position, intermediate options are not allowed.