The final stage of installation of doors or new windows is the facing of slopes. If you are mounted a beautiful, modern window, then the technology of finishing the window slopes can be performed using a wide variety of materials. For this purpose, plastic sandwich panels, sheet drywall, as well as the slopes can be decorated with PVC clapboard.

Facing - the thing is absolutely necessary, it will create the effect of the aesthetic completion of the generated interior.

Facing - the thing is absolutely necessary, it will create the effect of the aesthetic completion of the generated interior.

The material of this article will stipulate the main nuances of the decoration of the window of the window using the above materials.

Need to finish

The slope closes the seam from the mounting foam, which will be formed when installing the new window block.

The need to carry out this type of work occurs primarily due to the fact that in any case, when removing old windows, existing slopes will be destroyed. Secondly, after all, something needs to close the seam from the mounting foam, which will be formed when installing the new window block.

Much in the finish depends on the material used and the quality of work, since cracks and various kinds of damage should not be formed on the lined window slopes due to their flue or freezing.

To achieve the durability of the conquests constructed, it is necessary to fulfill their correct preparation: remove all the old plaster with them and, if necessary, be insulated with basalt wool or expanded polystyrene.

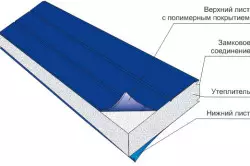

Speed Mounting Scheme from Sandwich Panels: wall, mounting foam, window frame, insulation, sandwich panel, rail, j-profile, C-profile, window sill.

Qualitatively decisions will not suffer from temperature drop, they never form condensate, while the properties of thermal insulation and sound insulation of the room will be significantly increased. For today, three ways of facing window openings are the most popular:

- using plastic sandwich panels;

- plastic clapboard;

- Moisture-resistant plasterboard.

The properties of the material for finishing play a very important role in both the point of view of practical applications and the aesthetic side.

Recommendations of specialists

According to experts, it is best to sneak by PVC molding or sandwich panels, as small cracks will be formed on slopes that are lined with plaster. This is due to the enhanced shock load and the temperature difference, which arise due to the operation of windows. And also due to the fact that the plaster does not have sufficient elasticity.

The PVC Wagon finish has the following advantages:

Lined PVC lining slopes have a complete view that will be well combined with a modern window style.

- Plastic can be mounted on the day of the window mounting, and the decoration of the plaster takes not one day (spatlement, drying, painting);

- The discontinued PVC wagon slopes additionally serve as a barrier of thermal insulation between the street and the room.

- No need to conduct periodic service;

- The slopes from plastic have excellent moisture resistance;

- Lined PVC lining slopes have a complete view that will be well combined with a modern window style.

Article on the topic: Types and features of the installation of pendulum loops

Recently, the PVC Sandwich panels are used quite often when construction work. This material has a number of excellent characteristics: excellent rigidity and durability with a small weight, excellent properties of thermal insulation and aesthetic appearance.

In these panels, the facial side is protected by a plastic film. Inside the material there is a foamed polystyrene, which has a cellular closed structure. Panels can be made both with one-sided and double-sided work surface.

Window slopes that are lined with sandwich panels have the following advantages:

The slopes of their PVC steadically carry the impact of ultraviolet radiation.

- sufficiently high quality thermal insulation;

- The premises will have additional sound insulation;

- high strength and long service life;

- excellent resistance to moisture;

- good resistance to the effects of ultraviolet radiation;

- Beautiful appearance.

As for trimming by plasterboard, it can be argued exactly that this type of building material is environmentally friendly, has a small weight and its installation is quite simple.

But not to indicate its basic disadvantages. First, this material is quite fragile. Secondly, it has the ability to absorb moisture. Therefore, before applying plasterboard, it is necessary to dry.

Application of sandwich panels

This material can be separated from any wooden or plastic windows that can have a structural width from 50 to 1500 mm.The sandwich panels are environmentally friendly material, which meets all existing sanitary standards, based on this when working with a sandwich panels there is no need to apply additional personal protection measures.

As a rule, the installation of slopes is made on the day of the installation of new plastic or wooden windows, but it is recommended to postpone the installation for the next day in order to enable the mounting foam to dry completely. To increase the thermal insulation parameters of the discovery from plastic, it does not matter whether you will be sided with sandwich panels or plastic lining, in any case it is recommended to mount the preceded layer of the heat insulating material. However, for the sandwich panels it is not necessary.

Mounting foam can serve as a heat insulating material. But it should be noted that in order to achieve the best characteristics of isolation, specialists are advised to install slopes and window sills at the same time.

Based on the fact that the configuration and section of window slopes can be the most diverse, today there are several methods for fixing the sandwich panels to the wall. Again, according to specialists, it is recommended to take advantage of the most practical and common one. This fixation of panels with dowels by mounting the ends of the panels to the basis of the slope and the further framing of these ends and fasteners. For this purpose, there are special plastic decorative corners.

At the end of the installation of plastic slopes, all existing seams (the adjoining of the sandwich panel to the window, the windowsill, must necessarily be treated with neutral sealant or glue, the basis of which is "liquid plastic" PVC. This sealant should be used because it does not have a sticky consistency, in contrast to silicone varieties of sealants, as a result of which, after a while, the seams will not turn yellow and contaminate.

Article on the topic: Panels for a tile for bathroom, toilet, kitchen

Facing plastic panels

The decoration of plastic clap - today the phenomenon is quite common, since this cladding material has a smaller value in comparison with the sandwich analogues. The only lack of plastic lining can be attributed to its low resistance to different mechanical stress, but this is not so important for window slopes.

Plastic lining, or wall panels is colored or white, empty, smooth panels.

Plastic lining, or wall panels is colored or white, empty, smooth panels, inside which the stiffeners are across the sheet across the sheet. Panel data are made with a thickness of not more than 10 mm, the width can be 250, 375 and 390 mm, and the length is 6, 3 and 2.7 m.

Specialists are recommended by plastic clapboard to separate the slopes in the panel buildings with the depth of slopes of the window to 250 mm, based on the fact that with greater depths it will be difficult to achieve the necessary rigidity and coating strength. Performing the facing of slopes with plastic clap, it is necessary to pre-lay insulating material. It can be basalt wool or mounting foam.

The PVC panel windows finishing technology has two types:

- Connection with an independent declvement "PAZ in the groove";

- "Comb in the groove" - a tongue compound.

The material panels can be fixed with glue, mounting foam or wooden rails using a building stapler. We should not forget that all docking places are necessary at the end of the installation process hide using an ornamental corner.

Sunsaw lined with lining panels acquire a unique inimitable style and bring to the room a feeling of comfort and warmth.

Differences of PVC lining from sandwich panels

Everything is sufficient simply: in the structure of plastic lining no insulation, it has a cellular structure, based on this property of thermal insulation of your window slopes will be minimized, if you do not perform the preliminary insulation. However, visually discovered from plastic lining look at no worse, in comparison with the slopes from the sandwich panels, although if you carefully look at, then you will certainly notice the difference.

After some time of operation, the lining of plastic can be simply compressed.

After some time of operation, the lining of plastic can simply suck, and all due to the fact that this material is hollow. PVC lining is great for the trim of balconies and loggias with their preliminary insulation. Only then will be practical and durable.

Therefore, initially perform thermal insulation of window slopes, and subsequently apply for cladding plastic lining will take you much more time and means than to use material for these purposes, in the structure of which is already contained by the insulation layer.

Article on the topic: Fliselin wallpapers: their pros and cons, as well as features

As mentioned above, the sandwich panels consist of PVC sheets and insulating material (polystyrene foam). This material is ideally stacked on the opening of the window, afterwards it will not be flawed and does not need any additional refinement.

Summing up the foregoing, you can allocate their main differences:

The scheme of the structure of the sandwich panel: top sheet with polymer coating, lock connection, insulation, bottom sheet.

- Different properties of thermal insulation;

- The moisture resistance of the material - sandwich panels react much better to moisture in comparison with plastic clapboard, based on the fact that the polystyrene foam is quite moisture-resistant material;

- Lifecycle - Window slopes that are made using sandwich panels, much longer will serve you in comparison with the slopes, made using plastic lining;

- The cost of installation work - the use of sandwich panels will be more expensive to you than the use of plastic lining.

Application of drywall

Moisture-resistant sheets of plasterboard are produced by the method of semi-dry pressing cellulose waste paper and binder based on plaster. This material has high thermal insulation properties and has increased thermal resistance. In addition, drywall is capable of maintaining the optimal humidity in the room by absorption of excess moisture, and if there is insufficient moisture level in the environment, it highlights it back.

The advantage of cladding window slopes with sheets of drywall is the low cost of the material.

The advantage of cladding sheets of drywall in comparison with the dissection finishes by plastic lining in the first place is the low value of the material. Secondly, the fact that when damaged of the slope there is the possibility of quickly fixing it. To do this, it will be quite enough to span the place of damage, and then paint it again.

The fixation of the sheets of material on the wall can be made using a special glue, putty, cement mortar, or a metal or wooden frame to pre-build and apply the screws in this case. The choice of a method for fixing moisture-resistant drywall needs to be selected based on the size and configuration of the processed slope.

In order to prevent moisture penetration and eliminate the reproduction of mold, before finishing the slope, the wall must be impregnated with primer deep penetration or moisture resistant. In order to increase the properties of thermal insulation, the slope is additionally insulated with plates of mineral wool or by mounting foam. It should also be noted that all the joints must necessarily be treated with neutral sealant.

After the slope is assembled, a plaster putty is applied with one layer.

After the slope is assembled, a gypsum putty is applied with one layer, and the reinforcing paint grid is preheated to the drywall and give it to dry completely. To give the angles of slopes of the neat appearance, a perforated corner is used, it can be both plastic and metallic.

The final point of the conciliarity of the slopes from drywall is their pasting with wallpaper or painting. Another of the positive points of the use of moisture-resistant drywall for decoration trim is that it can be painted in any color you need.