Penosole - perfect insulating material

Every day the selection of insulating materials is becoming wider and wider, so it is very difficult to choose the ideal ratio of price and quality. The newest materials that differ in low heat-conductivity include foamizol, which in the harvested form very much resembles a foam or frozen polyurethane foam. In fact, foamizol is a carbide foam, which has improved properties.

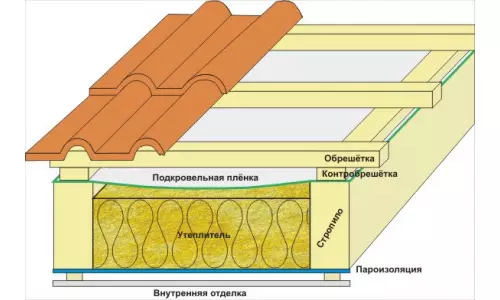

Diagram of insulation roofing by foamizol.

Product specifications

Despite the fact that foamizol is very similar to the foam, it has completely different characteristics and can be used for a wide variety of insulation options, including the ceiling insulation. Basically, this material is still used when the insulation of walls and ceiling, buildings under construction, filling in internal voids in the already built houses, insulation of attic rooms and areas under rafyles are required. In addition, the liquid "foam" can be injected under the decorative layer of the facade, that is, under the lining, siding, plasterboard and so on.

Penosop is a thick foam, therefore it is ideal for filling the cavities and when there is no cracks of any cracks, but also a ceiling.

In addition, the market also contains plates from this material, which, although not as effective as foam, but on the other hand, they can be mounted independently. Despite the fact that the foam and polyurethane foam are close relatives of foamizol, yet the latter is radically different from their "analogues" with its technical indicator. First, foamizol has a smaller heat resistance than, for example, foam and even polyurethane foam, therefore, to carry out high-quality insulation of the walls or the ceiling, it is enough to embed a total of 5 cm layer of insulation.

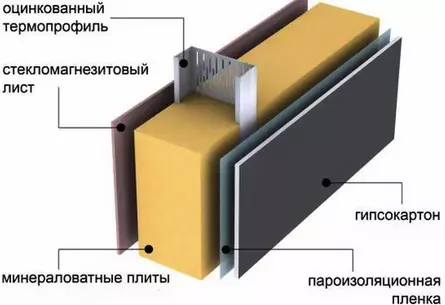

Thermopanel scheme.

Among other things, the advantages of foamizol who have made it more popular than foam or polyurethane foam, can be attributed to the fact that this material is absolutely safe from all points of view. The thing is that foamizol does not burn even at very high temperatures, but simply melts into a lump mass. In addition, during the deformation at "burning", there are no emissions of harmful substances in the air than neither polyurethane foam, nor foam be boasting. The thermal insulation properties of foamizol are out of all silence, and this material can withstand the temperature range from -50 to 150 degrees, not deforming and without changing its properties.

Article on the topic: Laying (installation) Plate of overlap

In addition, this material has high sound insulation properties, so it can be used not only as a heater, but also as sound insulation. Despite the fact that the frozen foamizole is quite fragile material and it can be easily cut or broken, it does not have rodents, which are so annoying insulation and can turn both foam and polyurethane in the duch. It also makes the durability of foamizol, because thermal insulation from this material can perform its heat-insulating functions of more than 70 years, without losing its qualities.

Wall insulation by foamizol: subtleties

Polyurethane foam and foam is materials that can be installed independently, because the foam is sold in the form of rigid sheets. While foamizol is the filling material, so without special equipment and the necessary skills to install it simply will not work, especially if we are talking about the insulation of the ceiling.

In order to form an insulating layer of foamizol, the following materials and tools will be required:

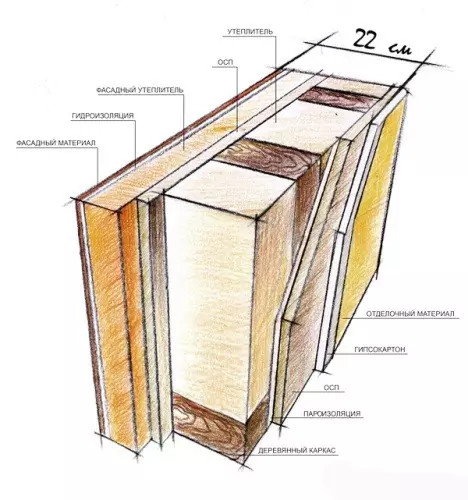

Wall insulation diagram by foaming.

- polymer resin;

- hardener;

- metallic profile;

- Dowel;

- carbide foam;

- Installation for the production of foamizol;

- compressor;

- drill.

As a rule, the insulation of the walls is carried out on the outside of the structure and also involves the installation of the protective facade. When working first, the holes are drilled in order to obtain full-fledged access to emptiness between the walls, and then under pressure in them foaming.

Next, the facade forms a suspension design on metal profiles, which will become not only the base for the future fill of the foam, but also the base for the decorative layer. The outer wall of the design is closed with any material that passes air, for example, siding. The distance between the siding line and the actual wall of the house can be from 5 to 25 cm, depending on which thickness will be a thermal layer.

Article on the topic: How to remove the creaking of the floor, without removing the floor: expert advice

The preparation of foam occurs using special technically means, due to which the dosing of carbide foam and its mixing with polymer resin, hardeners and water foam occurs. After cooking, the pressure mixture fills all niches and emptiness in the walls, which allows you to produce high-quality insulation. It is worth noting that foamizol hardened not as the polyurethane foam similar to it, so its installation is somewhat more complicated. The thing is that foamizol does not expand during the injection of cavity and niches, dense foam retains its source dimensions.

After pumping foamizol, it primarily solidifies in just 15 minutes, but for its full crystallization must pass at least 4 hours. After a complete hardened, the foamizol is very reminded by its appearance polyurethane foam, only has a brighter color. As a rule, when filling out all cracks and cavities, the foam is spontaneously squeezed through all the most minor holes outward, so the remnants of the visible foam need to be simply removed and painted. In technical terms, the insulation of walls by foamizol is quite difficult, so it is necessary to attract only qualified workers to perform it.

The ceiling insulation is usually not too different from the insulation of the walls in its complexity and technology, but still in this case the horizontal location of the ceiling plays a huge role, which allows the foam to spread better.