Although the parquet for the class of elite flooring, the question of how to eliminate the creaking of the parquet, often occurs. Over the years of operation, the quality of the floor is inevitably declining. The creaking appears, as it makes a parquet of a fully natural material that does not contain the preventive shrinkage of substances and components.

Parquet repair scheme.

The creak is unpleasant in itself, but even those whom these sounds are not annoyed, it is necessary to take care of the replacement and repair of the floor, as it is always the first sign of its critical wear. Before you eliminate the creaking of parquet, you need to find out what reason he creaks. There may be several reasons:

- loss of contact with the base;

- splitting planks of parquet;

- drying;

- groove groove;

- breakdown crest;

- exit from nests nails or screws;

- lack of gaps at the walls;

- Board movement relative to each other;

- Damage to one or more boards or slats.

A successful option can be considered a violence by replacing one or more boards, without complete floor replacement. If the majority of the dies or everything, it is necessary to make a complete dismantling and retraining of the foundation. After stacking, the parquet will need a squabble, grinding and lacquer coating.

How to eliminate the creaking parquet yourself

Parquet repair scheme.

Most often, the creaking appears due to the fact that the boards have become more active in relation to each other. A very much depends on the base, and it can be different: bitumen and organic, cement screed, plywood sheets or bitumen mastic. To eliminate the script of parquet yourself, the following tools will be needed:

- drill;

- drill thin;

- Scotch larger;

- wax;

- a lot of winds or special polishing fabrics;

- Polyurethane glue;

- Dowels.

Article on the topic: Brozent curtains in the garage: Advantages and disadvantages of structures

In some places, the parquet can be formed cavities caused by uneven evaporation from parquet moisture plates. In these cavities, dust and rubbish are stuffed over time, thus aggravating the problem. In the future, at the slightest movement, such planks produce creak, which is required to eliminate.

The creaking floor cannot be fixed with nails, since this method is enough for a month. After that, the creak appears again in much worse than before the form, since nails are inevitably swing and climb, sometimes splitting at the same time. It is better to use screws and screws for such purposes.

Elimination of the screenshot: the procedure for performing work

Technological table Characteristics of parquet.

Most often work is made using dowels and self-tapping screws. To pre-store a creaking parquet chalk to prevent errors when drilling.

First of all, you should try to find the local area of the Parquet. Together with the basis, in this case, it is required to drill a hole in a specific scripting parquet board so that the dowel fit into it. The hole is done in the center, if the base is concrete, it is recommended to fill in there immediately after drilling cement milk. This is a mixture of water in equal shares with cement that strengthens it in the drilling places. After the dowel is inserted into this hole, it is pushed to the very depth of the base and then delayed with the help of self-sustaining to each other. Successfully performed works are covered with putty in the color of the tree. For more efficient disguise places of additional attachment, you can bite the head in front of the spitting of the head.

To eliminate the script of the parquet board, you can use another, slightly different from the first method. The hole is drilled smaller diameter, and instead of a dowel and a screwing apply the technology of liquid nails. This method reliably connects with the base of the parquet board with the base, and the holes are then swept into the main color of the tree in the same way.

Article on the topic: Homemade gas burner

If the flooring laying was made on bitumen mastic, then the creaking with a construction dryer can be eliminated. They are heated by the base, and then all the boards tightly to the melted mass must be pressing. In this case, the main task is not to override the floor so that the boards do not catch fire.

The creak most often occurs at the old coating, which serves a long time, without repair and restoring procedures. Simplifying laying, often used a panel method when the parquet is made of shields on which parquet strips are fixed. Parquet, reinforced on plywood sheets, can be fixed in the case of a tubing pneumatic with parquet stiletts. But most often you have to change it completely.

Elimination of a violep with wax and other compositions

It is used in this case, a special lubricating composition of wax, a specially mixed with a solvent. In the floor there is several microkers in which this composition is introduced. Lubricant of this type can be on a water basis, but all these methods cannot be called the same radical and effective as the screed of the parquet with the base on the self-tapping screw. As a water lubricant, universal WD-40 is often used, which is well poured into small holes and penetrates everywhere.

If the creak is interspersed with a crackle, it most often means cracking the wood due to the fact that it was laid in an underwritten state.

Cracks need to sharpen, and potholes to cover with sawdust with sawdust, and then sharpen. But if the gaps are very wide, they do not have a special meaning to put them, as it will take repeated cracking. In this case, the replacement of the entire parquet board or the plank is inevitable.

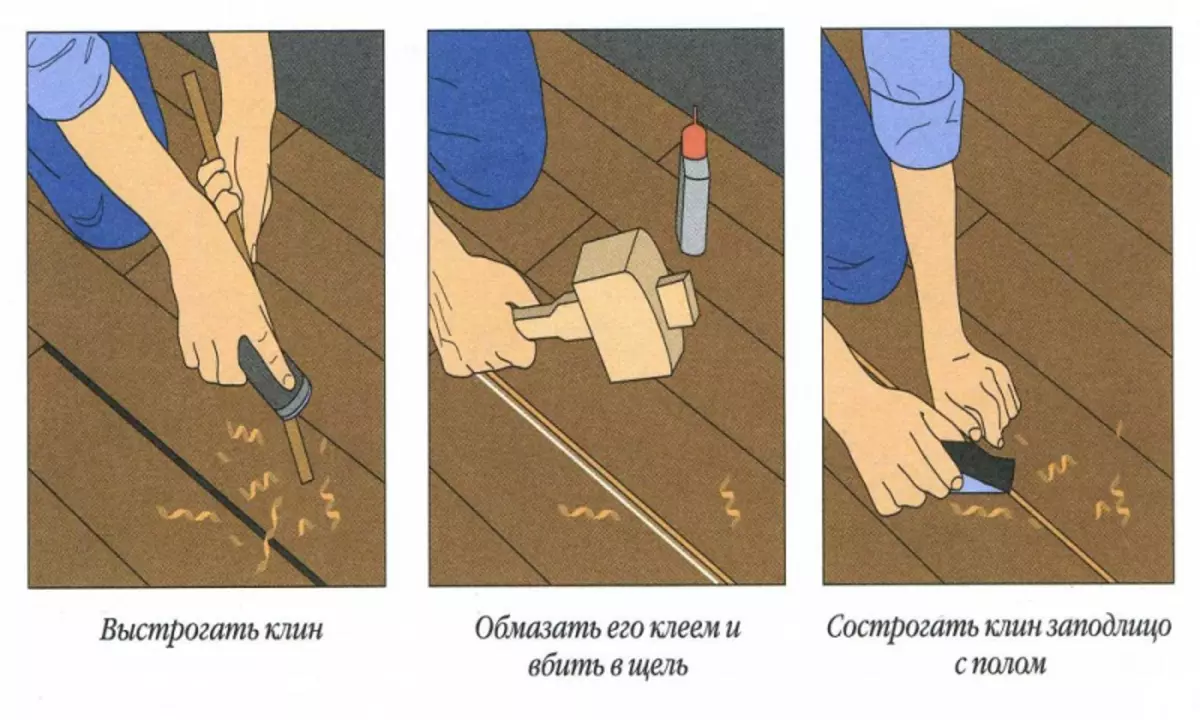

Often, the creak is eliminated by falling asleep in the floor slot of graphite powder mixed with talc. Sometimes the problem can be eliminated by scoring wooden wedges between boards. Any procedures for eliminating the screen of parquet should be combined with external restoration work, such as a lacquer coating or wax. It always provides a longer service life and parquet boards.

Article on the topic: Domain furnace and its use in the production of cast iron