With violation of the construction rules, the floor begins to creak. Only one means will solve the problem - eliminating the edge of the floor from the chipboard. Plates do not endure high humidity, so such a floor can not be made in sanitary facilities. Place plates for lags made of wood, which must first be processed by an antiseptic agent.

Floors from chipboard, if necessary, easy to dismantle and collect again.

Prerequisites for the construction of high-quality sex from chipboard

Tools and materials:

- screwdriver;

- Electrolake;

- Schlifmashinka;

- a hammer;

- fasteners;

- roulette;

- rail;

- chisel;

- Line.

Floor sheat circuit sheets DVP.

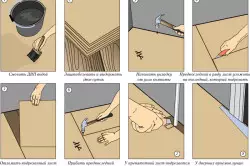

The average step size for laying the lag is 40 cm. Before starting construction, you need to close all the joints and holes of the sexual overlap. The draft floor should be clean and dry. On it a layer of no more than 20 mm pour clean dry sand. The top layer of sound insulation material from the Fiberboard sheets is layer. The lags well dried and antiseptic treated across the direction of light.

Laying of lag from the unreasonable sawn timber will necessarily create problems. The creaking of the floor will be distributed immediately after the sawn timber can dry. Lags must be laid on the same level, which is checked by the rail. At the same time, it should simultaneously concern all the lag. In places of detection of gaps under lags, lining makes, which stabilize their oscillations during the further operation of the floor. Correct irregularities can be peredentate the surface of the lags with a rubank.

Taking into account the distance between lags laid on the floor prepare the required amount of chipboard. They scold their width equal to this distance with the allowance required for the filing edges. This is usually 10-15 cm. Planning the laying scheme, you need to avoid a large number of joints. The allowable seam distance is 1-2 mm.

Article on the topic: How to make floor insulation in the panel house

For a more dense fastener, the edges of the plates are necessarily laid on the lags. To secure them in length, laid transverse lags.

How to eliminate the grazing of the floor from the chipboard

Repair of the floor with the help of glue and syringe.

In rooms with small passability, the floor can be made of chipboard.

During operation, it is possible to weaken fasteners, then when walking on the floor creap appears. If he has been many years old and there is an opportunity to make a new floor from more modern and high-quality material, then it is better to replace it better. This is the most expensive way.

To eliminate the floor creaking, you can screw up a few screws around the perimeter of such a plate. This is the easiest way, it is used most often. The floor will not be guaranteed to creak 2-3 years.

Another way is to install an additional support at the detection site of the defect. To do this, it is necessary to determine the distance from the soundproof layer (Fiberboard) to the slab of the overlap.

Having determined the plate to be repaired, the hole of the small diameter is drilled in it and with the help of steel wire measured it. It is necessary to purchase a self-tapping screw in length exceeding this distance. Muffle the screws in previously drilled holes. When touched by self-tapping plates of overlapping, the screwing is stopped, otherwise it is possible to raise the flooring.

Spilization of fastener heads with grinders produced only with the final adjustment (screwing or weakening).

Other repairs options

In order to eliminate the syringe, you can conduct partial repair of the floor from the chipboard. It is necessary to determine which part of the slab makes a creak and is subject to replacement. Make the markup so that when cutting out the defective area, do not get into lags. Cut it with an electroll. Prepare a bar of the desired height and put it between lags.

Secure a new sheet by self-drawing to lags and an additional barn.

This type of floor repair will break away from the screens.

Article on the topic: Using a completely glazed balcony

If the parquet floor is old, it is better to replace it. But sometimes it is possible to replace only several rivets. They need to smash the chisel and carefully remove, without damaging the rest of the coating. If the tightness of the floor is large, then open most of the floor covering. If necessary, you need to check the base of the floor, repair the screed, aligning it with a cement solution. Small defects can be eliminated by putty. If the rivets were laid on a wooden flooring or chipboard, then you need to install additional lags and lay the plates of the new parquet. They must be selected in size and drawing. Sometimes it takes a clipper in size. Old, but riveting-friendly rivets are cleaned of fastening residues. Install in place and check the installation correct installation. If necessary, they make a sewing grinding.