If you decide to change the old slate, then one of the option may be professional flooring.

Replacing old slate

First of all, we dismantle the old design.

Then remove the sump and the old slate.

We put professional flooring

On the same lags, screw with special self-draws, with a step in two waves. We establish a new plastic sampling, 15 cm wide, as it will serve as a bundle for the roof of the barbecue area.

For racks and upper beams, we use a square 7x7 cm., 1.5-2 mm thick. Racks fix on the floor, with the help of fittings and welding, from four sides. The back upper beam is installed in the level of low tide, the front - by 25-30 cm. Above, with a width between the beams 150-200 cm. Such an angle of water skate, the most optimal one. All joints are welded with welding. The length of the design is 8 meters, the width between the racks is 1.8 meters, the distance between the colonams was chosen so that they would neither load the recreation area (barbecue). With the step of the rear column 3-4 meters, and the front - 4-3 meters, the thickness of the square allows this step of the span. The ends of the beams are taken out by 50 cm. From all sides. Please note all the blanks are pre-painted in advance, for convenience, after welding, it is enough just to paint the seams.

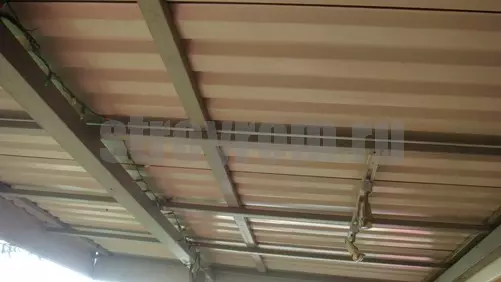

On the finished beams we weld the transverse ribs of stiffness, with a step of no more than a meter, it will give the strength of the whole roof. The length is crosslinked must match the length of the professional flooring. In this case, 2.7%.

Then we weld to cross the longitudinal ribs, and the professional flooring will be screwed to them. For longitudinal and transverse ribs, we use 5x2 cm rectangle, 1.2 mm thick. The step between the longitudinal ribs is 135 cm., What corresponds to two halves of a sheet of professional flooring. We screw the professional flooring, screws for metal, with a step in two waves.

Article on the topic: How to glazing the balcony with your own hands: Step-by-step instructions (video and photos)

Electrical wiring deposit into special plastic pipes. Confirm with metal plates with self-draws.

In the corners of the racks weld with decorative forging, flowers will be suspended. On the perimeter of the roof, we screw the metal profile (corner) for this professional flooring, it will give a finished view for this roof, and will hide all the ends from the rain.

Over the opening to the connection of two roofs, we screw the galvanized corner (Konk). In order to have heavy rain score inside.