Recently proposed by the construction market Outdoor PVC coverage with its universal design, characteristic and price has created competition to leaders in this segment: laminate and linoleum.

In polyvinyl chloride coating, improved properties of linoleum and external similarity with ceramic tiles. The plastic floor is pasted on the base of concrete, wood, other coatings, it is important that the base surface is smooth and clean. There are no limitations from PVC in the choice of colors, all sorts of designer ideas are implemented on the tiles.

Types and properties of floor PVC coverage

Apartments are recommended to lower household coating

Plastic floor is available in the form of rolls or square and rectangular tiles. Structural products are manufactured by multi-layer and monolithic, single-layer, and in the use of plastic flooring is divided into household, commercial and specialized.

In addition to synthetic components in certain types of products, natural minerals are used in PVC.

This coverage is convenient because you can combine tiles of different colors and textures.

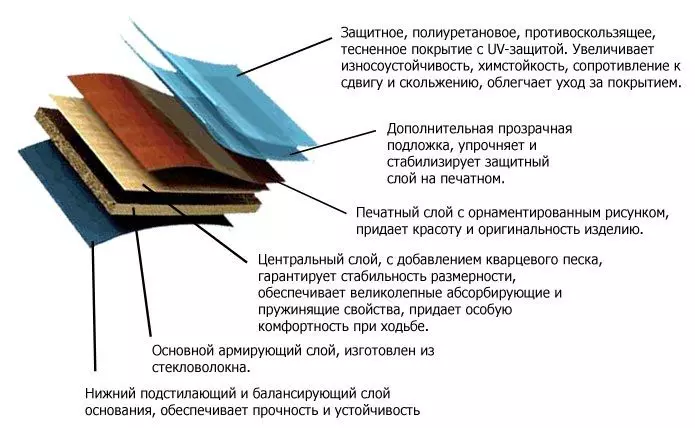

At the base of floor PVC floor coating layer of polyvinyl chloride with plasticizers, giving tiles rigidity and plasticity. Above the base layer is a decorative layer, dyed or with a pattern, and a protective upper layer of laminating polyester with an increased wear resistance.

Under the base layer, the profiled substrate providing stability tiles.

Thermoplastic polymer is also available in a single-layer embodiment, fully consists of polyvinyl chloride with a protective layer of laminating polyester. The color of the polyvinyl chloride layer is homogeneous and when the top layer is abrasion, the tile color does not change.

Quartzinyl tile, consisting of 5 layers, differs from PVC tiles by the presence of quartz sand layers with a binding component - Quartzinyl. This layer provides tile strength, sound insulation and moisture resistance and is 80% in the amount of the product.

Main characteristics

Properties characterizing products from polyvinyl chloride and Quartzinyl:

- The density of the material is 1.18 - 1.3 g / cm2;

- Tensile strength 10 - 25 MPa;

- compressive strength 6 - 10 MPa;

- Static bend strength 4 - 20 MPa;

- Brinell hardness 110 - 160 MPa;

- shock viscosity 7 - 15 kg / cm2;

- thermal conductivity 0.12 W / m * K;

- moisture resistance 0.0 1%;

- Soundproofing 19 dB;

- Wear resistance 32 class.

Article on the topic: Select siding under the tree: what is a house of house

In addition to the traditional PVC floor tile manufacturing option, the panel is available for connecting to each other with a spike slide system located around the tile perimeter and with click and lock lock systems similar to the laminate tile.

According to PVC quality indicators, the floor coating exceeds linoleum indicators and is comparable to some properties of laminate.

When choosing a floor cover and identical quality indicators, the cost of products becomes defining.

Application area

Household coatings are not designed for greater permeability

The spheres of use of the flooring characterize the products used depending on the intensity of operation and the load on the floor covering of PVC.

- Products for household use; These include single-layer and multilayer polyvinyl chloride panels with improved aesthetic properties, but with a small intensity of operation: in residential premises in the kitchen, corridor and on the terrace.

- Commercial use panels; These include polyvinyl chloride and quartz vinyl multilayer products with an enlarged protective surface layer that increases wear resistance. These are rooms with an average intensity of operation: small shops, entertainment clubs, children's facilities.

- Industrial products; These include multilayer quartz vinyl tiles with an increased base layer of quartzenil and a protective layer of polyurethane. This coating with increased strength and wear resistance can withstand multi-torrent mechanical load and absorbs noise and vibration. It is used in workshops, sports facilities, warehouses, concert halls.

- Quartzinyl tile, due to environmental properties, is used in the outdoor coating of rooms in residential premises and children's institutions with a guarantee of operation of at least 25 years.

PVC flooring

Place the tile on glue 10 minutes after applying

When replacing the floor covering, we determine what to do with the old one. If the old coating is in good condition, there is no damage and the surface is smooth, then the floor covering from PVC is glued to the old, pre-purified from contamination.

If the old floor has a geometry and the surface is damaged before learing the plastic floor, it is required to carry out the base of the old floor from concrete or wood revision, and then repair.

- We dismantle the old flooring, substrate and layer of insulation on the concrete base.

- Check the concrete floor to horizontal and damage. With a slight deviation of the surface of the concrete from the horizontality and the absence of serious damage, defects eliminate the bulk sex. Defects that can not be eliminated by bulk floors, eliminate the concrete tie.

- On the floor of the leveling concrete base, we laid waterproofing and slab insulation, which is closed by a vapor barrier film. On top of the film mounted black floor-resistant chipboard.

- On the prepared grounds are placed by polyvinyl chloride coating.

- Wooden coating We check for the presence of rot, cracking, warming of genital decks and lag. Boards and lags with defects change, then focused on the boards, eliminate the slit. After the screed, the coating is stuck, we remove the irregularities and paint. On the cleaned and leveling surface we applied primer.

- On the prepared base, we are placing PVC tiles.

The selection of PVC coating tiles is starting with the study of the material properties on the certificate and obtain information about the product manufacturer.

We select colors and drawings on the flooring panels, combined with the interior of the repaired room.

Article on the topic: Knitted curtains Crochet for the kitchen - Elegant solution

Features of work

We calculate the required number of panels, based on the floor area and tile size. When buying, the calculated tile volume increases by 10% for unforeseen cases during the installation of products and the possible replacement of damaged plates during operation.

Before mounting the tile, we enter the room where the repair of the floor is performed, and the day withstand for acclimatization.

Tile laying perform in drawings, ranging from the center of the room. To control geometry we use a laser level. The center of the room we find the intersection of diagonals. Through the center, we carry out two mutually perpendicular lines, forming 4 rectangles in parallel walls, forming 4 rectangles.

First put the tile in the center and only then on the edges of the walls, where the tile can be trimmed

The panel is stacked sequentially in each rectangle, gradually filling the floor surface. At the floor walls, if it does not fit completely, the tile cuts up.

The panel is glued to the dispersion glue composition. The glue is applied with a toothed spatula, with A1 - A2 inserts, on the surface of the floor at the rate of 350 grams per 1 m2, after 10 minutes on the glue that scored adhesive strength, lay the panel.

The rectangular shape panels are laid on the floor side along the room along the room, and square tiles are across the room. This arrangement of products allows you to hide joints with natural light and the floor looks monolithic. For details on laying material on glue, see this video:

The tiles are placed tightly to each other without a gap, no compensation gap is left between the flooring and the wall, since the temperature changes in the size of the panels does not occur on the temperature fluctuations.

Tiles with self-adhesive base are more convenient in mounting

After laying the panel, rolled up with a roller from the center of the room to the walls, squeezing air bubbles with excess glue. Excess dropped glue is removed with a cloth moistened with ethyl alcohol.

Floor coatings are available with self-adhesive layer at the base, which allows laying panels without glue, significantly reducing the installation time. The assembly work is capable of performing an employee who has no professional qualifications, but it is important that the surface of the base remains smooth and clean.

Article on the topic: What are the castles on plastic windows and installation methods

Sticking the panels with a split groove groove simplifies the installation process. It is not necessary to tightly press the panels to each other, and the laser level will be needed only at the beginning of the installation when applying axial floor lines.

After the assembly, the laid coating is rolled up with a roller, and the glue is cleaned. The PVC floor covering released with the click and lock system is assembled without glue into the floating plastic floor. Read more about laying tiles in this video:

The coating assembly begins on the wall opposite to the entrance to the room. A number of panels are placed tightly to the wall without a gap. Subsequent rows are collected with the displacement relative to the previous one, so that the joints of the panels in the ranks did not coincide.

Correct care

Polyvinyl chloride flooring is reflected in the rules of the manufacturer's instructions:

- Daily dry cleaning vacuum cleaner with soft bristle nozzle.

- Daily wet cleaning with a washing vacuum cleaner or a mop with a mop.

- In commercial premises, daily wet cleaning with a rotary machine and a neutral cleaning agent.

- Periodic reduction of glossy coating with a special means for polyurethane coatings.

PVC flooring, thanks to positive properties: durability, wear resistance, moisture resistance, sound insulation and designer innovation is recognized by many consumers, and the competitive price helps the product to increase the share in the flooring market.