Arched construction in construction is known for quite a long time. But earlier to use the arches in the design of the housing or other buildings were a privilege of nobility. Luxury palaces, churches and so on - this is what was the main direction in the use of arched structures. At that time, it was pretty hard in many ways. That is why their distribution everywhere began only in the 20th century. Progress does not stand still and with the development of technologies, installation work on arched arches has become available for wide segments of the population, as well as use in various fields of construction.

The entrance arched door is more than normal, since one-piece wood arrays are used for its production, while desired by metal.

Today it is no longer a luxury, but rather one of the most popular interior design options indoors or building design. Arched door with his own hands can easily decorate any room and make her design more original.

By carrying out individual construction, in the interior you can use the arches in the openings of the window and the door, when making the ceiling and so on. Of course, I want to note separately the design of the arched door. After all, it is distinguished by special sophistication and attractiveness. It is about it that will be discussed.

Varieties of arched openness

Types of arched doors.

Today it is very often in the design of both residential and premises of another destination, you can meet a variety of arches. It can be both inlets and interroom. There are a lot of their species. But if you think about the classification, you can divide them to the following types:

- Semi-Russian view. The most common for today.

- Gothic (fitted) arches. They are distinguished by the presence of an elongated shape that does not have smooth lines with a pointed upper part.

But this is not all, the first option is divided into several subspecies. It:

- Classic option. It implies the presence of a conventional semicircular shape.

- Ellipsoid. The name speaks for itself, their form resembles a slightly elongated oval.

- Modern style. Its use gives the arms a variety of original forms, having different kinds of protrusions and transitions.

- Romantic version of the arches. It is very simple, as it has a rectangle shape with a rounded upper part.

- Arches in the form of horseshoes (horseshoes). Their design implies the presence and semicircular forms, and forms with a pointed upper part. This option can most often meet in the interiors of different national cultures.

Article on the topic: Flexible watering for water: species, choice, installation, service life

Now a few words about the arched doors.

Arched Doors: Design Options

Interior arched door will help visually expand the small space of the corridor.

The classification of arched doors can be carried out in different signs. For example, according to the material used for the manufacture or features of their design. And one of the classifying signs is the place of installation. So, taking as a basis the last of the signs, arched doors can be classified on:

- Interior doors. As already understandable, they have a location inside the room. Their design is made of wood and very often has such elements like mosaic and glass.

- Entrance arched doors. This option finds its application in various buildings of public use, for example in stores. In addition, in its interior, they use various government agencies and trading or entertainment centers. Their manufacture implies the use of a plastic profile.

The next classification feature is the material from which arched doors produce. There is not a very big choice here. It is due to the complexity and existing difficulties in the manufacture of doors in the form of the arch. Allocate only 2 categories. It:

- Plastic. It produces profile designs, which are subsequently on the manufacture of doors, as well as windows.

- Wood. This material is recommended for internal use, but input doors can be made in construction of a private nature.

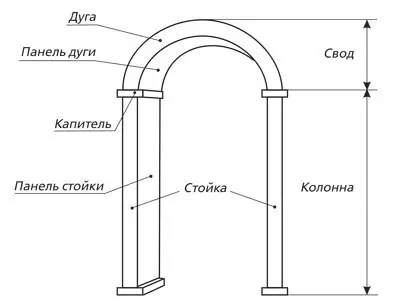

Scheme of arched opening device.

Finally, the nuances of the design are also a classifying sign. Focusing on it, you can allocate the following types:

- Doors having a form corresponding to the Obone. For the production of the design of this kind takes a fairly large amount of time. Yes, and the cost of them is not for everyone for pocket. Material for manufacture usually serves a tree.

- The door canvas having a standard solution with the arch. This option of doors has an already lower price, since the part in the form of a semicircle is installed separately from the web and remains stationary. In this case, you can use several versions of the doors, for example, hazard or sliding.

- Doors having only 1 sash. Used to design interroom space. Application as an input is also allowed.

- If the opening has large sizes in width, it will be advisable to use bivalve doors. Count 1 of the parts in the doorway, using such a device like a shatting.

Article on the topic: The membrane for the gas column

Making an arched door with your own hands: Is it possible?

This work is not simple, but it is possible to fulfill it with its own. Below will be the order of work and useful tips on the manufacture of arched door. I would like to note that the box for such a door will be better to make an order. To do this, you need to decide on the size and seek help from specialists. But the manufacture of the door canvase provides more simple technology.

Required devices

When installing a fixed arch above the door, it is recommended to use the level.

First of all, you need to take care of the availability of everything necessary for work. This applies to various tools and materials. Here is a brief list:

- Electric jigsaw equipped with wood sawmills;

- Electric milling mill (cutters must be 2 types: disk for the manufacture of grooves and cylindrical);

- Ribbon grinding machine (well if it is equipped with a skirt in different samples);

- 5 cm thick boards;

- Wooden wedges;

- Bruks of medium size and self-tapping screw (enough 4 pieces), the length of which is 30 mm more than the thickness of the bars used;

- Adhesive composition with waterproof qualities (for example, PVA).

Arch door leaf: how to do?

To make it, we need the width values in pure form. It is possible to calculate it in a simple way: from the total value of the width, take the thickness of the box and the estimated gap (usually 2 mm).

At the next stage, you need to decide on the size of the arch. For a harmonious view, it should be equal to half the width of the doorway. Finding out this, you can proceed to the calculation of the desired amount of boards. The location of the material (boards) will be horizontal.

When installing a fixed arch in the resulting cavity, you can "hide" all wires and cables.

Use only well-dried material for work. Using an electric milling mill, it is necessary to place the grooves. The protruding part of the groove should correspond to 2.5 mm. All grooves are performed by analogy with the first.

Article on the topic: We make a bin of storage of vegetables on the balcony in winter

The inner surface of the soldered grooves needs to be released from the dust accumulated in them, after which they can be treated with an adhesive composition. Then perform the connection of all parts and leave them without movement for high-quality drying.

The following actions imply a semicircular manufacture. This technology resembles working with plasterboard. Having placed a semicircular workpiece using an electric jigsaw, you need to trim it. Further, there is a grinder with the largest grain, then with small.

The remaining part of the door is made according to the principle described above. It will differ only on the position of the boards, it will wear a vertical character.

Please note that the canvas of the finished door includes 3 parts: the lower horizontal part, the shield from the boards located vertically, and the upper part in the form of the arch.

A thyroid method is used to connect.

For high-quality fixation, use glue and wedges for the backup. It remains only to perform the finish finish of the canvas of the finished door. What it will be, you will tell you your fantasy.