Circular saw is a productive, convenient and maneuverable tool, with which various construction and finishing works are carried out. If you need to perform large volumes of tasks, it is quite difficult to work with manual circular. In such situations, an excellent assistant becomes a table for a circular saw. It can be collected independently of boards and plywood. The saw itself will be placed at the bottom of the table top, and the toothed disk will be held in the slots. The saw turns on, the disk starts to rotate, the sawn timber is supplied and its sawing occurs. If you wish, you can collect a great table for circular saws with your own hands. There is nothing difficult in this work.

It is difficult to work with large volumes of wood with a regular circular, so it is better to install it on the table.

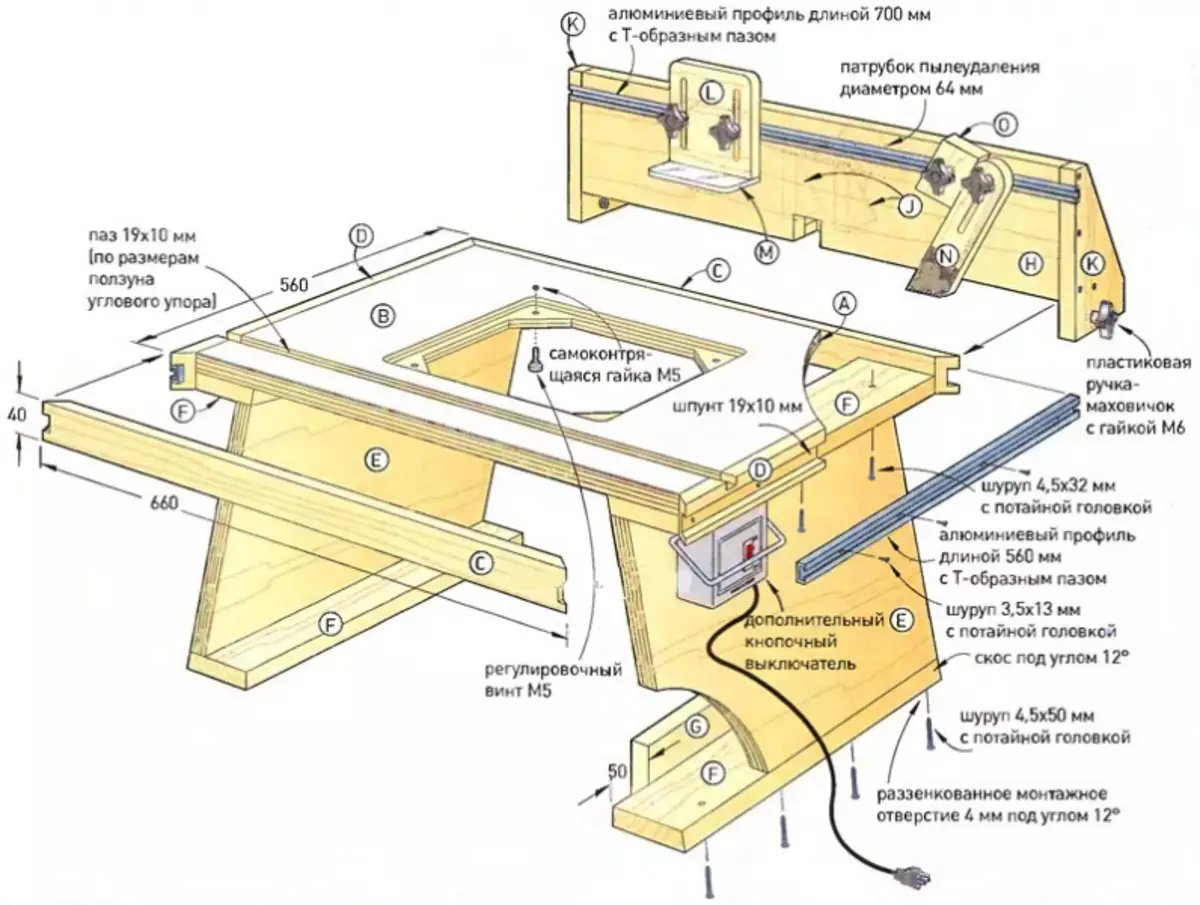

Table design for circular saw

Before collecting a circular table with your own hands, you need to thoroughly think of its design. At this stage, your task is reduced, first of all, to the load calculation, which will be displayed in the future. Collecting the table for a saw with your own hands, take into account the power of the unit. So, for industrial high-power tools, it is recommended to use a reinforced steel welded structure. In the case of a home saw in the device, such a powerful design is not necessary. It will be enough to assemble the table for a saw with your own hands from boards and plywood.

Circular table table.

When planning to make a table for a saw with your own hands, you need, as already noted, take into account the power of the tool. In the home workshops most often used saw up to 800 W. At the same time, it is necessary to take into account the frequency and volumes of the work performed. For example, during the construction of the house there will have to cut a much larger material than with any other conditions. Experts do not advise you to buy saws for a house more powerful than 1200 W. In the case of a domestic workshop, this simply makes no sense.

The higher the power of the circular saw and the higher the volumes of the work performed, the more reliable, the table you create is stronger and more stable. Circular saws of the professional class are mounted on the base from metal products. In some cases, such tables are even fit into the floor, since due to the vibration, the operator can briefly lose control over the saw, which will be sufficient to obtain injury. The creation of this table requires certain skills to work with special tools, welding, etc. Assembling the same wooden table for a home saw is available to almost every person even in the absence of such experience.

Article on the topic: Applying Venetian plaster. Master Class. Photo. Video

Preparation for table assembly

Table assembly scheme.

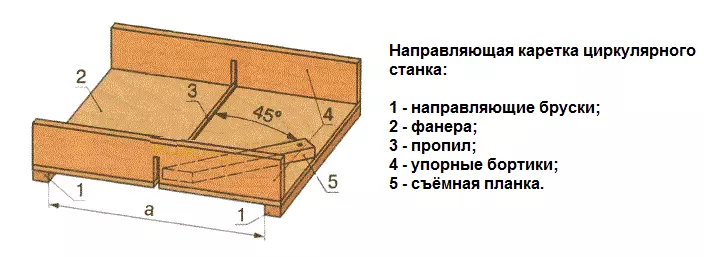

The easiest option of the table for the circular is the design of sufficiently thick plywood and boards. Plywood in this case will be used for the manufacture of table tops. Directly the table top will be stationary. The tool must be installed under it. Previously in the lid, a slot is created, which will move the saw blade.

Call the table sizes, first of all, with a guideline. You should be comfortable and comfortable to work. The instructions consider the average and most common sizes. You can change them at your discretion. The height of the table is 1-1.15 m. Lenten choose with regard to the nature of future works. If most often you saw long boards, the table cover also needs to be done long enough. With a tabletop length, more than 2 m design is recommended to equip an additional pair of supporting legs. Without them, the table will vibrate strongly.

The thickness of the plywood used for the manufacture of the countertops should be from 5 cm. Plexiglas are suitable for the same purpose, fiberglass. From using the Master chipboard, it is recommended to refrain in view of not enough high strength of the material.

The cover is polished and varnished in several layers. This will ensure the required slip of the processed materials. The best option is to strengthen the metal sheet on the worktop. This will increase the reliability of the surface and will extend the life of the product as a whole.

Materials and tools for work

Table topics.

The table for circular saw requires a mandatory presence of guides, due to which the higher accuracy of the sawing of materials will be ensured. Guides are boiled from a metal corner. Clamps usually use clamps to consolidate to the tabletop. Guides are not recommended to make stationary. It will be more convenient if you can change their position in the future.

Prepare materials for self assembly:

- Plywood. If you wish, you can use another material for the table top.

- A metal sheet.

- Bar 50x50 mm.

- Board 50x100 mm.

- Clamps in the amount of 2 pcs.

- Metal corner for the manufacture of guides.

Pre-collect all the necessary tools:

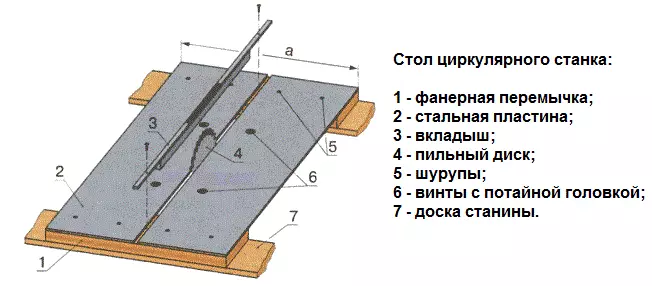

Stanna Circular Machine.

- Hacksaw. If possible, it is better to use the electrolovka instead of it.

- Screwdriver.

- Electric drill.

- Manual milling cutter or machine. In the absence, you can do without them.

- Roulette and ruler for measurements.

- Corolnic

Article on the topic: Santa Claus and Snow Maiden with their own hands

After the preparation of all tools and materials you can start assembling a homemade table. Some wizards use old dining and kitchen tables for this. But it is not worth counting on a greater durability of such products. It is better to do everything yourself, "from scratch". So you can assemble a comfortable table, fully appropriate to your needs and requests.

Step-by-step table assembly instructions

Table of circular machine from steel plate.

First you need to form a worktop. Take a plywood sheet and mark the markup. The edges of the sheet must coincide with two edges of the lid. Drink the workpiece with a hack or electric lobby. If you wish, treat the spike cutter. This is optional, so you can skip this stage. In the case of a table for circular saws, reliability is more important than a beautiful appearance. Perform draft countertops using sandpaper.

At the bottom, prepare a slot for the disk. Measure the sole of the circular saw. To make it possible as convenient as possible, remove the saw blade from the tool and simply circle the desired part of the saw.

Next you need to take a manual milling mill and choose the material about 8-10 mm. In the absence of cutters, use chisel. The result will be the same, but it will take more time and effort.

After the installation of the landing place is completed, try the stove and make the required adjustments. Seat the slots for the saw disk and fasteners. If the disk should rise and descend, the table must be equipped with a pendulum mechanism. In this case, the shape of the slot must have a type of truncated pyramid. The top of this peculiar pyramid should be sent down. For the manufacture of the frame of the lifting mechanism, it is better to use metal corners cooked with each other.

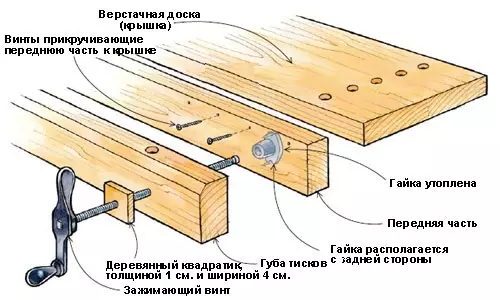

Build frame and setting legs

Table guide carriage for circular.

Next you need to make marking under the transverse and longitudinal rails. In the case of this table, they perform the rigid rigid function. Make it from the wrong side. Planks are made from Brousa. It is necessary to prepare 2 longitudinal ribs. Lenten pick up the tabletop length. It is enough to take away from it at 8-10 cm on each side. Transverse slats should also be 2. To determine their length, take 8-10 cm from the tabletop width on each side.

Prepare the nests for the self-tapping screw. The rails are fixed in such a way that the lid is about 8-10 cm acted for the edges of the frame. It is important to make the most reliable and durable mount. The first self-tapping screw at a distance of 4-5 cm from the edge of the rail. The self-samples themselves are mounted in a step of 20-22 cm. Details need to be drilled through. Hats of selflessness should be completely recessed in the material of the table top.

Article on the topic: Game zone for children in the country

Cross ribs are first attached. To ensure maximum reliability of the table, it is necessary to pre-mark the edges of the rails with carpentry glue. Turn the design of the clamps and fix the self-drawing. Leave the table cover until complete drying, after which the same scheme install longitudinal rails. Tighten the frame parts and install several mounts on each side. After that, you can remove clamps.

For the manufacture of legs, use bars. The height of these elements is selected individually in accordance with the growth of the operator. It is more convenient when the countertop is located at the thigh level. Before installing legs, construct them from 1 sides so that the processed side goes to the angle. As a result, the base of the leg will have a slightly large area than the peak.

To fasten the legs, the metal corners are best used. You need to slightly squeeze them in such a way that the base of the improvised table is located. Thanks to this, the bed will become more stable. The mount is performed using bolts with washers. They need to install hats outside. If you install differently, in the process of work, you can be drunk about protruding attachments.

Additionally, the legs are recommended to pull the diagonal slats.

It will make the design even more reliable. Reiki should be installed in pairs from the side of the homemade table.

Carefully polish the surface of the table top and cover it with several layers of varnish. Instead, you can fix with small self-tapping screws a smooth metal sheet.

At the end, the installation of a circular saw to the place intended for it is performed. Additionally, you can apply a markup to the surface of the table top, which will contribute to a more even and proper processing of the sawn material.

Control elements such a machine must be taken out on the outside of the table top. Usually they are fixed on some feet of the table. Performing this stage of work requires some electrical engineering skills. With their absence, it is recommended to contact the appropriate specialist.

Thus, there is nothing complicated in an independent assembly of the table for circular saw. Large temporary and cash costs it does not require. You will spend much less on the materials than on the finished factory, and the quality of the product is not worse than the instruction. Good job!