Industry not so long ago to produce metalplastic. Pipes from this material became popular in the sphere of heating of private and apartment buildings. Installation of such a heating system is fairly simple and can be performed even a non-professional.

The device of the heating system from metal-plastic pipes is not easy, but knowing all the nuances with this can be cope without attracting expensive specialists.

Selection of heating scheme

It should be immediately noted that the heating scheme in which metalplastic is used is based on various factors, such as the location of the heating boiler, the location of the rooms and other similar.

One way or another, you can allocate general principles for constructing the heating schemes for which they can be classified:

- collector schemes;

- one-tube or two-pipe schemes;

- Schemes with top and bottom of pipes.

There are other types of schemes.

It is worth noting that in many ways the heating scheme depends on the location of the gas boiler, if it comes to a private house that has such a heating element.

The thing is that the gas boiler can only be installed on certain conditions, that is, in compliance with all the requirements and holding of all these distances to some items according to the boiler technical documentation.

In addition, in many respects, the type of heating system scheme determines the water supply of water supply pipes to the house. There are other factors.

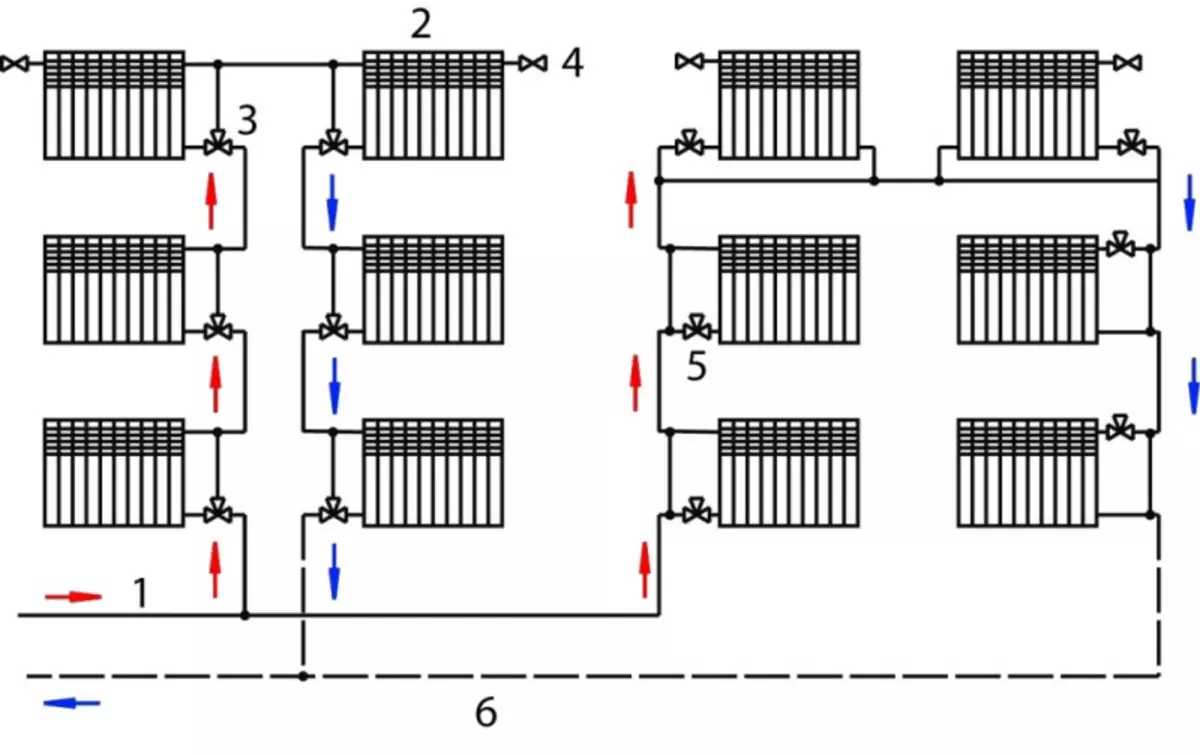

Scheme of a single-tube heating system: 1 - feeding line, 2 - heating device, 3 - three-way crane, 4 - air intake, 5 - regulating faucet, 6 - reverse highway.

So, with regard to a specific type of system, each of them can be distinguished both positive moments and negative. For example, a single-tube heating system from metalplastic is good, rather, for a small house used as a giving, in which the number of radiators does not exceed 5 units.

This is due to the fact that with a single-tube scheme, each subsequent radiator will have a smaller temperature than the previous one. With small amounts, the temperature will be approximately the same, with a large - the last radiator can never warm up at all.

Article on the topic: Calculation of the cabinet Coupe do it yourself - frame and doors

A positive point of such a scheme is that the amount of material being expended is much less than any schemes.

As for the collector scheme, it requires the largest amount of material from all existing schemes. However, adjusting the heating temperature of each individual item is so simple that it will easily compensate for all costs. In addition, the distribution of heat between all elements is almost perfect.

Something average between the two schemes described above is a two-pipe heating scheme. It requires slightly high costs compared to one-tube, but smaller - compared to the collector.

Heating according to such a scheme can be with the lower layout of the pipes and the top.

Installation of radiators, gas boiler and other elements of the heating system

Installation of the heating system, where metalplastic is used, starts with the installation of the boiler, radiators and other individual elements of the heating system.

It is worth noting that the installation of gas equipment should be carried out only by qualified employees from the relevant service. Independent installation of a gas boiler may result in serious responsibility.

Metal-plastic radiators are durable and durable. They are distinguished by large heat transfer and environmental friendliness.

As for heating radiators from metal plastic, they can be attached independently. At first, the places of fastening of radiators are selected. They are attached to the walls using special brackets. Brackets, in turn, are attached directly to the walls using anchor bolts. The holes in the walls are drilled under them, and then the bolt itself is screwed into the outer part, securely fixing the bracket.

If we are talking about cast-iron radiators, then for every 3 sections one bracket is assumed, but less than two brackets on the entire radiator should not be.

After installing all sorts of equipment, for example, a pressure gauge, if the gas boiler is not equipped, or any locking reinforcement can be proceeded to directly working with pipes.

Work with metalplastic

Metal plastic is quite strong material. Therefore, work can be carried out without special restrictions and requirements. However, some rules still have:- The installation of pipes should be performed only at positive temperatures above 10 degrees;

- If metalplastic was stored at least for some time at lower temperatures, then before starting work, he should be given a little adapt to the temperature;

- All such work should be made upon completion of the finish on the walls of the house;

- cutting metalplastic with the help of a special tool - scissors;

- In the process of installation, it is impossible to change the bending of metal plastic to the fracture, special rims should be used;

- All pipes are fixed in mandatory to walls using clamps or clips.

Article on the topic: Interior of the hallway in a private house: how to make a candy from the corridor (39 photos)

It is worth a few words to say about cutting such pipes. Cutting metal-plastic, as already mentioned, best with special scissors or pipe cutters. You can, of course, use and hacksaw for metal. Only after cutting the edge of the piece of pipe should be cleared with sandpaper to align it. You can use a simple sharp knife for this purpose.

Connection methods

There are several ways to connect such pipes for the heating system two main:

- with the help of compression fittings;

- With the help of press fittings.

The first method is good in that the use of compression fittings greatly simplifies all work. Such fittings do not require any special tools, with the exception of the above-mentioned scissors.

Besides them, maybe you may need:

- set of horn keys or adjustable key;

- FUM RTI;

- Calibrator.

FUM RENTA can be replaced by ordinary palauls with a special sealant.

As for fittings, they can be of various shapes:

- corners;

- tees;

- Adapters and so on.

All fittings have a fitting at its end, which contains one or more sealing rings. In addition, there is a clamping ring and a naked nut, which presses the pipe and fitting with each other.

Before connecting the pipe and fitting on the pipe, the ring and nut from this fitting are put on. Now you need a calibrator. It serves in order to create a smooth round shape on the end of the tube. If this form is not, then in the process of fixing the fitting and pipe, sealing rings on the fitting can be simply damaged, which will lead to leaks.

After calibration, the pipe is put on the fitting. Further tightened to place the clamping ring and a cape nut, which is spinning over the thread to the stop. The panel or fum-tape is pre-wound on the ring.

Nut is delayed with not very much effort. If you attach too much strength, the nut just burst or dispel the thread. Tightening should be continued until the characteristic metals screen appears.

Article on the topic: Nizhny Novgorod, climatic construction district

As for the use of press fittings, the installation can be divided into two types, although the division should be considered conditional:

- with the use of crimping couplings;

- using press fittings.

This method requires a special tool, for example, press ticks. This tool can be mechanical or hydraulically. It is worth noting that each type of press fittings requires the use of its type of tool, which differs in design and the principle of action. For example, the granular press fittings require a special expander.

In addition to this tool, the one that was specified above will be required.

The method of bending of metal-plastic pipes

In the installation process, it is often necessary to change the direction of the pipe, that is, bending the metalplastic, and sometimes even 90 degrees or very close to this value. In this case, it is necessary to use, as already mentioned above, special rims.Mandrels are springs. They can be two types:

- internal;

- outdoor.

Naturally, bending the metal-plastic pipe is required not immediately at right angles - it will inevitably be bent and breaks, - and gradually, that is, the arc.

With this method, there is one rule that it says that the bend radius must be 7 or more the diameters of the bending pipe. For example, if the pipe has a diameter of 20 mm, then the bending radius should be at least 140 mm.

If you need to bend the pipe at a right angle immediately, then you need to use angular fittings.

Fastening pipes to the walls

Pipes are fastened with clips to the walls. The clips themselves are fixed on the walls by means of self-tales. Then the pipe is simply inserted into the clip to the characteristic click.

Clips should be installed every 40-50 cm or more often, which depends on the diameter of the pipe.