Recently, owners of private houses and apartments establish additional heating of the floors. This allows you to increase the effectiveness of the heating of the premises, since ordinary radiators are not able to evenly distribute heat. The warm floors system saves on energy consumption due to the possibility of adjusting the necessary floor temperature.

True, such a prerogative applies only to the water heating system. Warm electric floors do not contribute to savings on electricity. However, experts argue that film or warm infrared floor gives such an opportunity. It is this system that is accepted for linoleum. This is due to the low temperature of the film heating, which is required when laying a warm floor under linoleum.

Before starting installation, you should choose a reliable flooring. Not every type of linoleum is suitable for the warm floor.

Choosing an outdoor coating

The optimal option for laying on the warm floor will be the natural type of linoleum. The fact is that it does not contain synthetic components, thus, when heated above 28 °, the material will not be released toxic substances. Moreover, it is much better tolerates constant heating, the threat of appearances of stains or other troubles.

However, the high cost of the natural linoleum of many stops. In this case, preference is better to give the polyvinyl chloride material of heterogeneous type. This is a multilayer linoleum that meets the requirements when laying on a warm floor.

High-quality material has the following indicators:

- Wear resistance.

- Strength

- Moisture resistance.

- Hygienicity.

Try to avoid linoleum that does not have the relevant certification. Her absence speaks only about one - before you fake. It is often accompanied by filling toxic substances, when heated that will begin to evaporate. This will lead to health problems, linoleum will quickly fail, covers stains and wrinkles.

In this regard, it is important to be interested in quality certificates for the product. Moreover, the responsible manufacturer will always indicate the material features on the roll. Among the indicators there will be marked with an indication of compliance with the warm floor, its type and the desired heating temperature. No type of linoleum can be heated over 28 °. Even a high-quality synthetic product will inevitably begin to distinguish toxic substances.

Article on the topic: How to make a round lamp of lace with your own hands: 2 ways

The optimal heating temperature of the linoleum surface without prejudice to health will be 25 ° -28 °. The exceedable indicator will result in the surface of the surface, in the worst case the material will start melting, the threat of ignition will arise.

When choosing a linoleum, pay attention to its foundation. Too thick product will reduce the "effort" of the warm floor for no, since heat for the most part will be concentrated in linoleum, and not indoors. Choose something average between thin and thick material.

Usually adapted to the warm floor of the product have an optimal thickness. If you decide to save on the facing, it will end the rapid output of the material. After a month, it will have to buy high-quality material again.

By selecting the necessary type of linoleum, you can start the installation of a warm floor system.

Laying infrared film

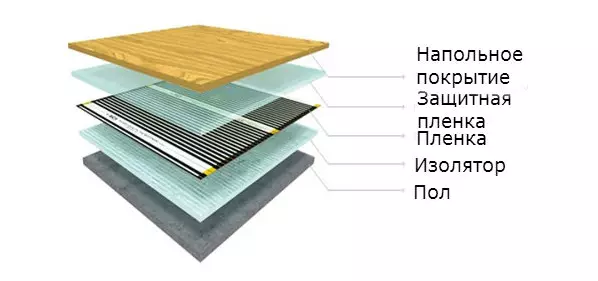

Film warm floor under linoleum is a thin polymer flooring, which is mounted carbon or graphite strips - coolants. Silver and copper conductors supply a current to the strips where it is converted to IR radiation. The resulting electromagnetic field is very weak and has no harmful effect on human health.

Infrared film very simply lay. The manufacturer's instruction is highly available explains the contact connection scheme. Installation of the system is carried out on a prepared base. Is it worth mentioning that it should be smooth and without flaws.

Before starting installation, it is necessary to immediately prepare all the necessary materials:

- Warm floor system with all components.

- Insulation.

- Parosolation.

- Plywood sheets.

First of all, the foundation is prepared. It should be smooth with a maximum drop of 2 mm on 2 m². If the difference is greater, you should pour the floor by self-leveling mixture or cement-sandy solution.

On dry, smooth, without bugs and cracks, the base can be mounted a warm floor system. But it is advisable to apply primer. Stage work is reduced to the following steps:

Article on the topic: White Tulle - Nuances Selection of Material

- Determine the place for the thermal sensor in the wall. The distance between the floor and the thermostat is 50-100 cm. Make a mark. If you want to drown the sensor in the wall, you should make a niche in the concrete using the appropriate tools. But usually the sensor is left outside.

- Next, it is necessary to note the path of the wires to the thermostat on the wall. Follow the bandwidth of 20-30 mm wide from the floor to the sensor tag. This place needs to be laid for laying wires into it.

- The next step will be the laying of the insulation to the floor. It is recommended to acquire a heater with a reflective basis - foil. It can be a foam. The basis of this material is thermal insulation coated with reflective foil. By purchasing such a material, there is no need for laying and insulation, and an additional reflective material. The presence of thermal insulation when installing the IR-floor is required. Otherwise, heat will go to the stove, and not to the room. The insulation is pumped with a metallized scotch in the joints.

- Film installation is made on the insulation. The location of the furniture is calculated in advance. The film does not fit under it. It must lie on the open sections of the floor, freed from furniture and technology. Crop the material is necessary according to the indicated dottedira, otherwise important heating elements of the film will damage.

- The next step is to connect the contacts of the film. The manufacturer provides detailed schemes for connecting the system. Once all the wires are connected, the conductors are output to the sensor in the wall. If the wires are planned to be dragged in the wall, you need to pick them in a corrugated tube. It is already mounted in the designated niche in the wall. Conducts to connect to the sensor according to the manufacturer's scheme. All communications on the film must be isolate and bleed in the insulation. This will not allow constant pressure to compound during operation.

- After connection, it is necessary to check the performance of the system. If everything is fine, you can continue the installation of the IR floor.

- A layer of vapor barrier is placed on the thermal film.

- The plywood sheets will be mounted on it, which are nailed in the film-free places to the draft base. Linoleum laying is made on the fane.

Article on the topic: We make a beautiful rug from old things with their own hands

Mounting linoleum is made as usual. The only nuance is its laying on the working infrared floor. You can glue or fix the material with a bilateral tape after two days after laying a linoleum for a warm base. Measure will allow the material to adapt to temperatures.

Installation of a warm floor under linoleum will not take much time. Connection work is quite simple and do not require special skills and skills. The main thing is to carefully study the manufacturer's instructions for connecting contacts and comply with the installation standards of electrical equipment.