After installing the door, the walls adjacent to it - the slopes - they have a smoking look. Perhaps the fastest way to put them in order is to separate the laminated panels. It can be MDF or chipboard. There is no particular difference. The main task is to choose a drawing and a shade to the tone of the door or other finishes in the room, and make door slides from MDF or LDSP easy. And there is a way that requires a minimum of time.

The slopes from the laminate are made quickly, the appearance at the same time, at least, good. No special skills required, you need to be able to handle a saw or a jigsaw - to cut fragments of the desired size. The rest of the work are simple and uncomplicated: glue, mounting foam, wooden planks, self-tapping screws. Does not even need plaster as if you bring slopes from drywall.

The easiest way

The easiest way to close the door slope can be using "G" -d-like volunteers, they are usually made from MDF. All that in this case is required - cut off the desired depth, correctly and clearly cut into 45 °. Then you need to wash the end part with liquid nails, on the inside, apply the mounting foam and press everything to the wall.

The easiest way to arrange slopes - use "g" -nya panels

And, as always, there is "but", and serious. The first is these tricks expensive. The second - they are only in major cities and in specialized outlets. The third is usually available only a few colors, everyone else is supplied under the order. Therefore, more often use other ways to facing the MDF door slopes.

Installation of slope for liquid nails and mounting foam

If the discovery width does not exceed 20-25 cm, the laminated panel can be installed on liquid nails and the mounting foam. The method requires a minimum of time costs, and the result is good.We are preparing elements of slope

Door slopes from laminate consist of three parts: two side and one top. If the slopes are made at an angle, then one edge of the sidewall will be bevetled.

Article on the topic: Decor of the present and decorative well in the country (20 photos)

So roughly looks like "Pattern" for slope from MDF or laminated chipboard

Measure the distance from the door jamb to the angle in several places, cut off the bar of the required width and height. Cut sidewalls should be a pair of centimeters above the desired length - just in case, suddenly missed the size. You can cut off, but exit - no.

Sidewines try on, insert the top. If the edge turned out on the same level with the main wall, and the gaps near the door box are minimal - everything is done correctly. If there are flaws, they correct them.

Cutting off the item, trying on their place

Then the outer edge of the chipboard or MDF is triggered - stick to the ending film: you feed the platbands you are not to the very edge, so some part will be visible. Therefore, it needs to be re-organized. Without a trim, you can do if the edge is separated by a decorative corner in the tone. But it is from plastic, and how well it will look - the question.

Stick the ending film is easy. It is on adhesive basis. Only the edge should be smooth and clean - without dust and dirt. It is smoothly glusted to the strip of the ending, then take a dry x / b fabric that does not melt, and through it you stroke the end end (on medium power). It is glued then tightly, but all irregularities are visible, so discharge smoothly.

If you manage to choose a plastic corner in the tone, it looks good, and the works are less: it is glued to liquid nails or silicone

If a telescopic platband is used at the finishing stage of the discovery, under it with a cutter, in a sealing end, a groove is made. The width is exactly under the thorn of the platband, the depth is a little more required so that he is good "sat down." For an ordinary platband from MDF nothing is needed. It is simply glued to liquid nails.

Installing slopes

Having finished all the preparations, begin to install slopes from MDF (laminated chipboard). The end, which is directed to the door, is riveted with liquid nails. The composition is better to take transparent - it will not be visible. The jamb, to which the MDF is glued, degrease. By pressing the sidewall, it is exhibited in the right position, checking the verticality and observing the same indent. Then they dug it and wait until the glue will dry out. After 5-7 minutes, the fragment is installed in place, existing the position relative to the walls.

Article on the topic: Adhesive for EXCLUSIVE Wallpaper, General Overview

The second sidewall is installed in the same way, and then the upper part. The top will additionally squeeze: above the place where it is joined with the sidewalls are installed spacers. This will not give the finish to progress and additionally "clamps" the sidewalls.

Having installed all parts of the slope from the MDF, at the top put the clins

Fixation

After the wedges inserted, check as far as everything is worth correct and smooth. If everything is fine, take foam, and in the interval between the panel and the wall put the "Lats" - apply a small amount of foam islands. They must be all the depth, but be non-strokes. All the volume is not necessary: and a lot of foam will be required, and can exacerbate. Therefore, do precisely islets.

After the polymerization of the applied foam, the slope fragments are kept rigidly. Now you can start filling the empty space. It is also more convenient to seal foam, but not for the whole depth, but only ahead.

The procedure for fixing slopes from laminated fiberboard

After hardening the foam, its excess is cut with a knife. You can proceed to the finish finish.

Installation of trimming

This section of the work passes standard: first measure and cut off one side bar, then upper, then - the second sidewall. Trial of all folded and checking the accuracy of the docking, the platbands are sitting on a foam or liquid nails - depending on the situation.How to sting the slopes is described here.

Door slips from MDF on the planks

If the slope is large (more than 25 cm), additional supports are required for stiffness: foam may not be tight enough. In this case, the planks are fixed. These can be sawn timber or metal profiles. Attach the planks can be vertically or horizontally. The scheme of installing a discovery from MDF panels with vertical strips is shown in the photo below.

How to attach wide slopes from MDF

Planks are attached to a dowel (they are used more often) or self-tapping screws - depending on the material of the wall. After the supports are fixed, the slopes are cut in size, the order of action is similar. First, the ends and places where the slope is adjacent to the plars, are riveted with liquid nails, the panels are flipped for a few minutes. Further, all actions are exactly the same.

Article on the topic: Installation of slopes on the entrance door with your own hands: Watching, finishing MDF and plastic (video)

If, as in the figure, the joint of the panel and the wall is ideal, you can do without bothering the slots and installing platbands. In this case, work is generally a bit.

Door slopes from MDF can be installed on horizontal strips. They are aligned so that they are all in the same plane. On the side of the four supports, at the top - three (retreating 10-15 cm from the edges and in the middle). Next, all the technology is the same.

How to make slopes on PVC windows of plastic.

Slopes from laminate

Often after repair remains some quantity of building materials. Why not adapt them? Making slopes on the door from the MDF, the material must be bought. If after the laminate flooring, you have a certain number of planks, you can also take away from them. Works will be greater than when using a solid fragment, but the material is free.

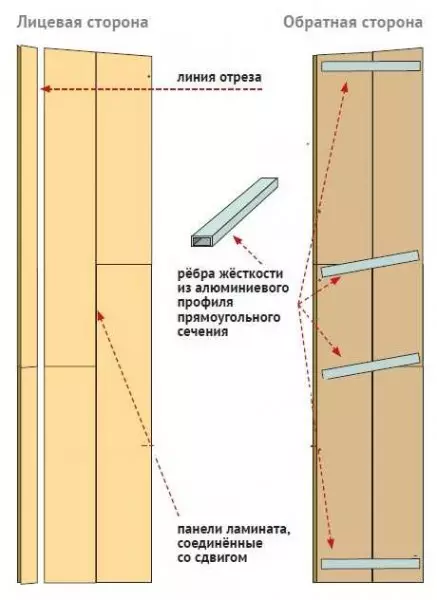

From the boards of laminate collect the sidewalls. They need to be shifted with a shift, the locations of the joints with the insole to fasten the planets - it is possible from an aluminum profile - it is less by weight. If necessary, the edge can be trimmed. How to make slopes on the door from the laminate, see the photo below.

From Laminate Planks, you can make team slopes for the door

You can install them on the mounting foam. To give greater stiffness to apply it to the back side of the snake and press the wall well: you can not leave large gaps in this case: the material will be fed.

In the video below, the door slopes from the laminate are made in the panel house. Sleep width is small - 7-8 cm, the sequence of work is described clear. Useful video lesson.

In general, homemade slopes from laminate on the entrance doors are better not to install: there are often large-sized things, and the laminate is easy to damage even heavy bag. This type of separation is better used for interior doors. The load is significantly less there. At the entrance it is better to make door slips from MDF or laminated chipboard, showers from drywall, but the most reliable - plastered.