Regardless of the form of the fireplace, it requires a unique framing, which should still be harmonized with the stylistic direction of interior design. To give a certain appearance, the portals are finished finishing a fireplace, marble or artificial stone, tiles, decorative plaster, plasterboard and other materials. Everyone can give elegance or nobility a fireplace.

The choice of materials for finishing the fireplace depends on the type of room interior.

Let's give some practical recommendations regarding the facing of the man product.

Tree application for decoration

The tree is perfectly combined with many interior styles. Fireplace shelves are performed from wood and carry out the design of the portals. The finishing of the fireplace with wooden elements is very much reflected by the construction, adding the magty of magty and luxury. A red tree and an oak massif uses special honor. The finish of them is quite expensive. Plates of DVP and MDF - their budget alternative. These materials are more resistant to different impacts and much more durable.

Wooden finishing of fireplace structures does not cause concerns even for wood focus wood models when it is performed on all standards and rules.

The scheme of finishing the fireplace furnace.

The main requirement here is the observance of technology. If it is decided to transform the wood fireplace inserts from a tree, then they should be placed too close to the hearth. Mandatory processing of all wooden elements by means of flame retardant in front of them.

The furnace is equipped with a protective screen to prevent sparks from scattering far beyond the structure. When decoking false structures, these measures neglected by these measures.

Making a portal for an electrocamine, a niche space for the installation of a firebox should have dimensions somewhat large (approximately 5 cm), rather than the firebox. It will contribute to good ventimation and eliminate the overheating of the heat chamber and the probability of fire from the tree portal.

Article on the topic: Wallpaper for the living room

Design of fireplaces tree

To separate the fireplace tree, enough in the already existing framing add inserts from wood (for example, pilasters, arches, columns, etc.).

Sequencing:

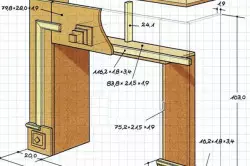

Fireplace tree finishing scheme.

- Billet (4 x 2.5 cm), which will perform the role of a frame for the entire decorative design. For a stone portal or trimmed with tiles, it is necessary to prepare polypropylene tubes for screws.

- Marking for the frame and doing the victorious drill drill holes under the plugs. It should be accumulated. Then the tree drill is made of small sizes of the opening on the rails for screws. Rakes are attached to the base, wrapping the fastening details of the screwdriver. The rails installed with the help of carpentry synthetic glue are closed with decorative overhead elements. When covering with a tree of false structures or electro-cycling, plow joine glue.

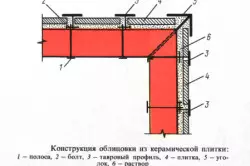

Camera design tiles

A rich selection of shades and patterns of the tile allows you to perform the author's design of the fireplace installation. The following types of tiles are suitable for finishing the fireplace:

- Maitolikova - glazed for cladding;

- terracotta - unlocked facing;

- Ceramographic.

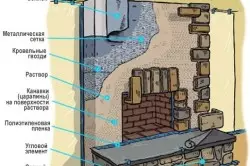

To properly bonded the fireplace surface with tiles, respectively complies with technology.

The first thing is to prepare the surface, dusting and degreasing it. Paint believes. If it is impossible, the surface is covered with a reinforcement grid with cell sizes of 1.5 x 1.5 cm. Made each product in size. The trimming of the elements is performed by the tiles or a disk with a diamond spraying of the Bulgarian.

Facing chart of fireplace tiles.

Prepare everything, go to the masonry. Laying begins to bottom, in advance to withdraw and exhibit a diagonal. Tile laying on the fireplace surface is made using heat-resistant glue or special mastic. Otherwise, after some time, the ceramics will stretch from the walls due to the temperature difference and will begin to crumble.

Upon completion of the laying of the first row, the accuracy of the masonry is checked by level. As needed to make adjustments to rubber hammer-inquark. The remnants of glue from the tiled surface immediately remove. Slightly fall out with this - and removal can damage the tiled glaze.

Article on the topic: How to grow strawberry on the balcony

When laying a facing tile, plastic crosses are used. With their help, it turns out to create uniform connecting seams between the products on the entire area of the fireplace installation. Laying tiles is considered unfinished if the seams are not made. A rubber or silicone spatula is used to apply a solution.

Design of fireplaces of plasterboard

Plasterboard cladding for the fireplace is considered to be a classic option as the framing of the mantelpiece. The structure of the scenery from this material will save finances and take their own creative abilities on the full power. Plasterboard is convenient to use when it is necessary to create all sorts of shapes with different geometry.

More often, plasterboard involve electrotope and falsecamines for facing.

Finishing the fireplace plasterboard plates performed in the following order:

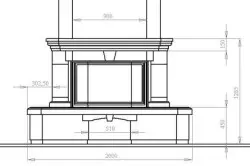

The scheme of the design of the fireplace plasterboard.

- Start with the sizes of the portal. On the wall and surface of the floor draw a pencil sketch of the future product.

- The wall plane in which the fireplace will be installed is mandatory covered with sheet asbestos. The main frame is made from PN 28x27 mm profile. Mounting to bricks or concrete is produced by screws 0.6 x 6.0 cm. Self-cutting (0.35 x 5.5 cm) on wood is suitable for wooden partitions.

- Another of the profile is bonded by clouds (0.35 x1.1 cm by self-drawing). The strengthening of the entire construction is created at the expense of metal profile of PP 60x27mm. Then make a frame for a focal niche, using a 60x27 profile and not forgetting about gain.

- The frame installation procedure is monitored by attracting the level. Before separating the frame with plasterboard material, check the accuracy of the electrocouper niche. The electrical device is installed in a niche to make sure that the ventilation gap is provided on all sides. Take into account the plasterboard trim and facing with a heat-resistant cafeter.

- After the triautors, take out the furnace and weave the whole frame surface with plasterboard. In accordance with the technological flue holes, performed exactly the same in the portal case. All corners outside are masked by a plastic or galvanized corner.

- Before starting decoration, the entire surface of the fireplace frame is thoroughly applied. After that, covered with soil and expect complete drying. Take the Venetian plaster and, diluting it with water according to the instructions, are applied by a thin layer by spray. To obtain a bright coloring to solution, a color is added, which is acquired separately and in full on the entire solution of plaster. The kel is mixed immediately with all the amount of solution, because it will later achieve the desired shade will not be very easy. Apply a plaster composition with a roller, a spatula or brush with a rigid bristle.

Article on the topic: Bordeur for the bathroom - types, selection and installation

Good luck in your work!