The veneer refers to wood materials having a type of thin sheets of wood whose thickness ranges from 0.5-3.0 mm. Veneer, as a rule, pastes on wooden panels or DVP, thus giving a more aesthetic and attractive look.

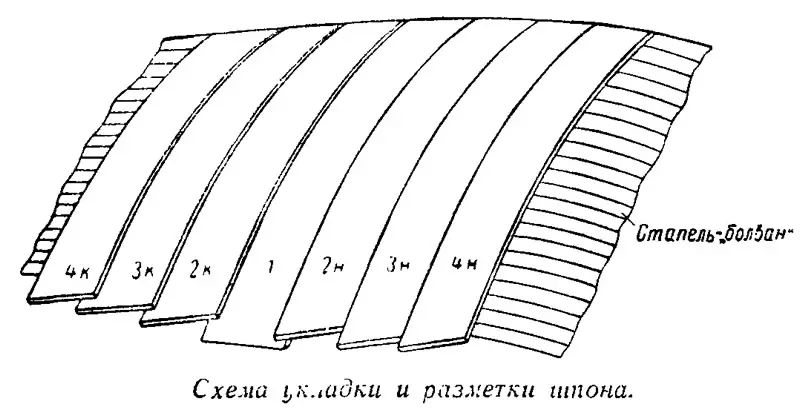

Scheme of laying and marking veneer.

Very varieties

Veneer is divided into various types. Depending on the production method, the material is divided into:

- lucid;

- sawn;

- planed.

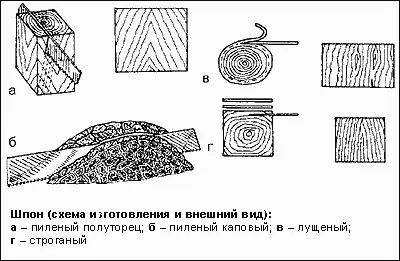

Types of veneer.

Depending on the appearance, the veneer is divided into the following types:

- Natural. Such material has the form of thin sheets of natural color and structure. The main task in the production of such a material is the preservation of the natural nature of the tree. The advantages of a natural veneer is its environmental friendliness, the preservation of the unique structure of the tree, an attractive appearance. Products decorated with material similar to wood array products, but are an order of magnitude lower, and the weight of the structure is less.

- Color. In the manufacture of a colored veneer, its surface is scratched, processed by a mourn. As a result, the material is distinguished by a wide range of colors.

- Fine Line. This type of material is obtained as a result of the reconstruction of the imperial veneer obtained from soft wood. Initially, blocks are generated, of which there are later veneer of various structures, drawing and color of natural wood. This method allows you to imitate the valuable rocks of the tree in the manufacture of material from cheaper wood. As a result, the veneer has a more aesthetic look, and it is cheaper.

Veneer has found an application in the manufacture of various designs and products. The most popular material for finishing doors, furniture, for the manufacture of plywood. Also quite often apply in the production of guitar hull, during decorative work. In addition, the veneer is widely used in car tuning, for the interior decoration.

It is worth noting that some manufacturers are saved on high-quality glue and varnish, using poor-quality compounds. All this significantly affects the environmental purity of the product.

Article on the topic: Replacing the loops of balcony plastic doors

Methods of manufacture of veneer

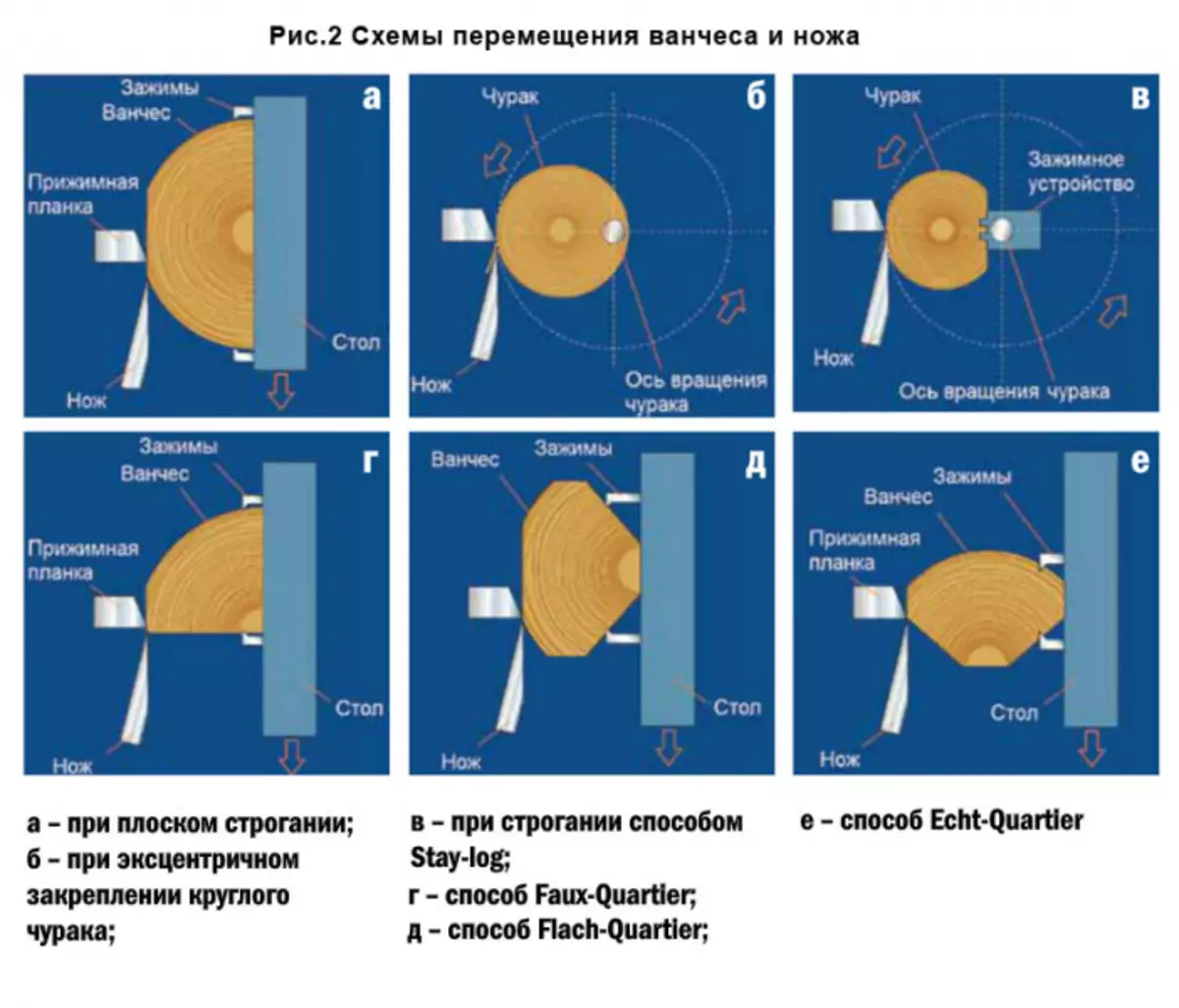

Veneer manufacturing circuit.

As mentioned above, the veneer according to the method of manufacture is divided into three types. Let us consider in more detail these methods for the production of material.

- Difficulty method. In this case, specially prepared wood is used, when rotating which the top layer is removed using a special machine. During the production of veneer, soft and solid rocks are used. With this processing, the upper layer is cut off spiral. As a result, large sheets of veneer are obtained, but the drawing is not very clear and bright. Therefore, the peeled veneer is most often placed on Phaneur.

- Planing method. With this method, the top layer of wood is cut into a transverse or longitudinal direction. Make a veneer of this type only from solid wood. As a result, a sheet of material is quite large density with a bright and beautiful pattern. Therefore, the planed veneer is used in the production of furniture and doors.

- Sawing method. In this case, the veneer is obtained by unsinking from the prepared logs of sheets with a minimum thickness. The material obtained by this method is the most expensive, since a large amount of waste is formed during production.

In the production of veneer it is important to pay attention to the quality of the wood itself. The tree must have a smooth trunk with a minimum number of bitch and branches. The trained log is inspected by a specialist and is determined by it on this or that method of processing.

Making veneer with your own hands

You can make veneer and do it yourself at home.

Production of planed veneer.

Of course, for this you need to have a special tool and have at least some snorkeling on working with wood.

For the manufacture of sawn veneer, it will take a blank in the form of a bar. The surface of the workpiece is drawn by vertical stripes with a step of no more than 12 mm. After that, the timber is fixed in the workbench and is crucified by leafing with a jigsaw.

Article on the topic: Types and features of the installation of pendulum loops

The planed veneer is initially manufactured similarly to sawn, but then the surface is processed by a mechanical or electrical plan. It is better, of course, choose an electric margin, as it provides better processing quality. In this case, it is necessary to work extremely carefully that the thickness of all sheets of veneer was the same.

For the production of implant veneer, it will take a blank with a round cross section. Therefore, it will take a grinding machine to obtain a cylindrical shape billet or a ready log. Further veneer manufacturing technology is similar to the processes described above. The only difference is that a large sheet of material is obtained.

Further processing of the resulting veneer depends on the personal preferences of the owner. To obtain the required effect, grinding, treatment with paint and protective compositions.