Among the abundance of the species of interior doors, a wooden version takes an honorable place. Despite the fact that the wood doors are quite expensive, after installation you can not worry about problems that may arise throughout their operation.

The doors made of wood are resistant to mechanical exposure and have high sound insulation.

In addition, such a product has an excellent appearance, with proper operation it will last for many years. In order to save money on the purchase and installation of a wooden door, everything can be done independently. If the installation can be made without any problems, the question of how to make the door of the door himself, causes many doubts.

Features Wooden Interior Door

The most important and mainst advantage on which the consumer draws attention is the environmental friendliness of the material. The tree creates a beneficial microclimate and absolutely does not harm human health. Specifications can also be isolated:

- aesthetics;

- high level of heat and sound insulation;

- Resistance to mechanical loads.

Today, with the help of modern technologies, doors covered with veneer can be created, which is capable of imitating any wooded rock, but they differ from the doors made from a natural tree.

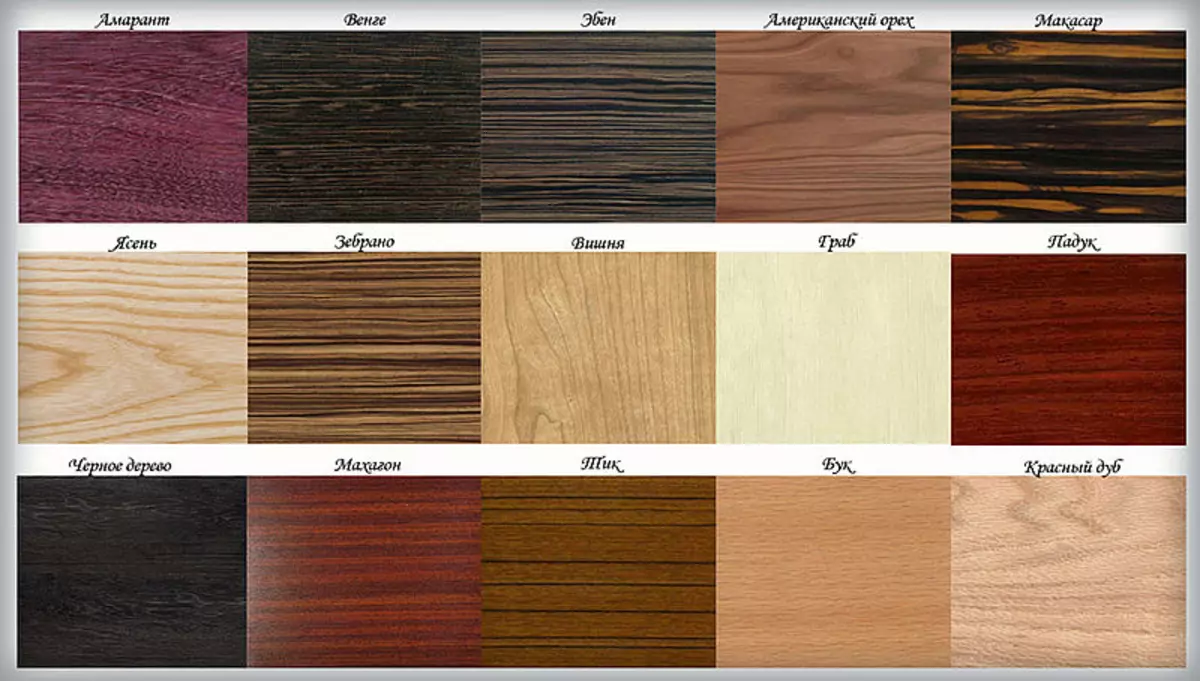

Types of wood breeds for the manufacture of doors.

Like any product, the doors made of wood have shortcomings, but, by observing production technology and proper operation, all flaws can be minimized. It is very important to pay attention to such a property of wood as absorption. Absorbing moisture, the door can change the form over time, this happens in the drying process. To prevent this process, you need a canvas door to cover with varnish.

It is worth noting that the qualities will be directly dependent on the process of production of the canvas. It should be well dried, saturated with oil solution and processed by a hot ferry under high pressure.

Materials that can be used to create a door

For the manufacture of doors you can use deciduous wood, such wood is characterized by high density, beautiful color and an interesting texture. Among the most sought-after breeds today you can allocate:

- oak;

- ash;

- beech;

- cherry;

- nut.

Article on the topic: Shade do it yourself

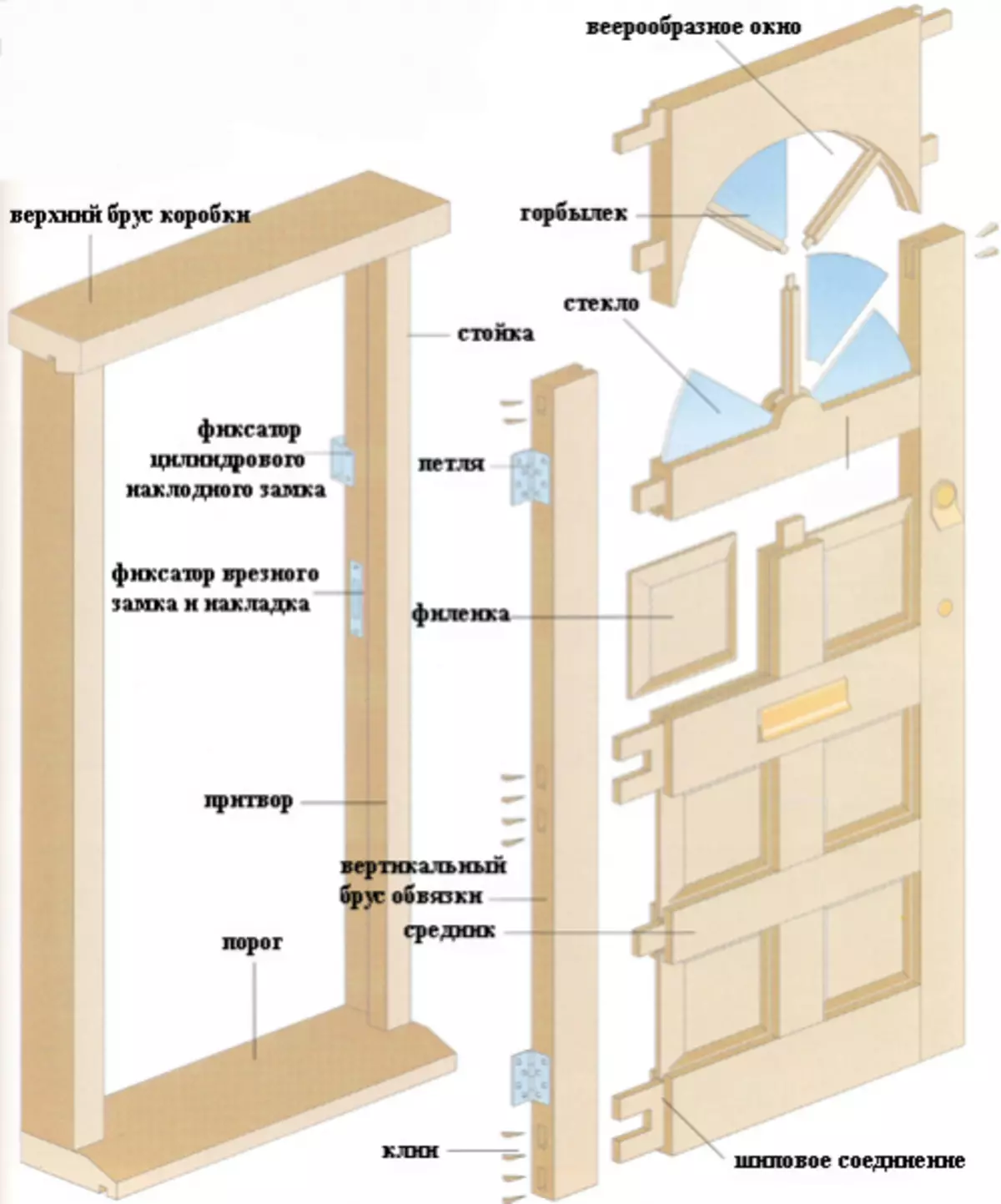

Wooden door making scheme.

A more budget option is an array of pine or glued option. Despite the low cost, pine doors will serve not one decades, the main thing is to comply with the manufacturing technology and correctly care for them. In order to make such a door more attractive, it can be covered with veneer veneer. The value of the veneer is not very high, but such a door will be almost indistinguishable from the original.

Making the doors on their own, you can use the glued array. This material today is very popular. To make such a material, the lamellas of dried wood, glued together with each other special composition. Each layer of lamellae is glued perpendicular to the previous one, this location makes the door very durable and reliable.

In order to independently make a wooden interroom door, it is necessary to have an idea of the main stages of work. The product performed independently may not be so ideal as factory production, but this option will be much cheaper.

Preparatory stage of work

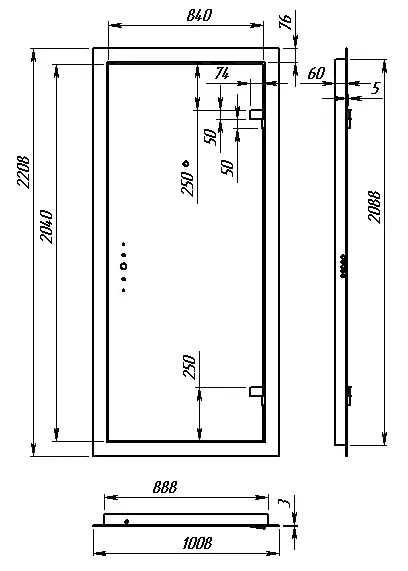

Drawing door.

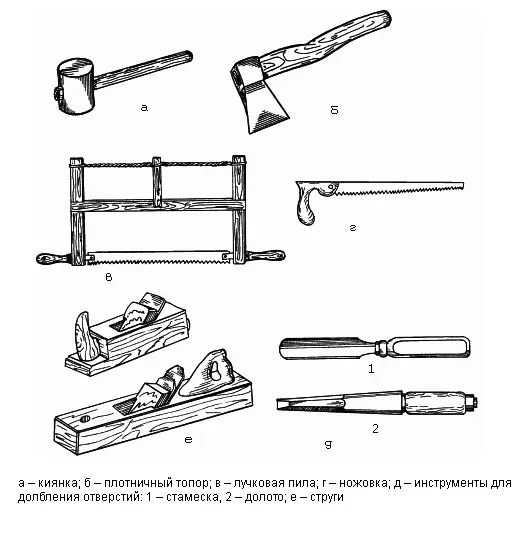

First you need to prepare tools with which work will be carried out. This is a standard carpentry set, which includes:

- wood hacksaw;

- plane;

- the chisel, you can several different sizes;

- clamps;

- stusla;

- markup pencil;

- line and roulette;

- Corner construction.

The presence of all necessary tools will significantly speed up the work.

After the materials and tools are prepared, it is worth assessing the front of the upcoming work. The first thing that is worth starting is to define the size of the web, it will depend on which box is installed in the opening or will be created. If there is a threshold in the box, then the gap between it and the door can be from all sides of 2 mm. If there is no threshold in the box, then the canvas should be less than 2 mm from three sides, and it is necessary to leave the lumen 8-10 mm below. This is necessary so that when opening the door it is not damaged, the floor covering and the door could be opened without problems and close.

Article on the topic: What color to choose wallpaper for the kitchen: designer tips

Manufacture of door web

Tools for the manufacture of a wooden door.

- To make the doors, you can use fiberboard. It is necessary to cut two canvases from it that will respond to the sizes of the future door. When cutting sheets, it is very important to withstand all the angles of 90 °, otherwise the door may not fit into the box, but it will look like this product. To create the door of the Fiberboard, it is necessary to choose the most dense, without various deformations - scratches, dents.

- For the manufacture of a frame to which the WHP sheets will be attached, you must purchase an inch unrestogolous board. The tree breed here does not play a big role. It is worth paying attention to the weight, the door should not be too heavy. For the frame it is necessary to cut off two long pieces, which will correspond to the length of the product, and three pieces in the width of the entire door. The edges of all billets need to stall well.

- The assembly of the entire design is carried out on a flat surface. This can be done on the floor, but pre-cover the floor with paper or newspapers. The first on the floor is laid by a sheet of fiberboard smooth side down. Long blanks from the board are laid out onto the sheet, followed by a piece of sheet width, a rectangle should form. The frame must be completely combined with the edges of the Fiberboard.

- Determining where the top and bottom will be, you can start a markup. In addition, it is necessary to determine whether the glazing will be in the doorway, if so, then at this stage it is worth conducting all the marking. The accurate location of the boards is also marked for the connective spikes, this markup is carried out at the place of intersection of the long and short workpiece. To avoid unforeseen situations, all the workpieces are worth numbered or sign. This will facilitate the assembly of the design.

- After that, it is necessary to make connecting elements - spikes. When stamped spikes, you need to be very careful. Using the pink, it is better not to finish, it will avoid full dipping. At the end, the sizes can be customized using the chisel.

After the spike is ready, the design must be decomposed again on the floor and check all connections.

Invalid is the protrusion of any size.

Article on the topic: Wallpaper in a children's room - 110 photos of the best ideas of design. Preparation and combination options.

It is very important to carry out all the work on the perfectly level surface, because after the assembly the deformation is almost impossible.

Finishing stage of installation

Fiberboard is attached to a wooden frame with a special adhesive composition. To do this, in places, the mark must be applied a layer of glue. After gluing for greater reliability in the upper parts of the wooden structure, screws are applied. It is very important that the hats of the screws did not go above the Fiberboard. The second sheet of fiberboard is attached in the same way to the frame with the help of glue. In the process of work it is necessary to control so that all the angles and the edges converge. After such a design is glued, it must be put under load. For this purpose, the door is covered on top of the Fiberboard, only then the load is evenly distributed differently.Extra moment: Trim blasting veneer

To give such a door to the finished look, you can use veneer. This is a very subtle material that imitates any breed of wood. In order to separate the door with it, it is necessary to prepare the surface. The surface should be perfectly smooth, there should be no scratches, bugs, chips. In addition, the entire surface must be treated with grinding paper. For sticking of the veneer, special joinery is used, which is evenly applied to the surface of the door and on the veneer itself. After applying glue must dry out a little over 10-15 minutes.

After the time of time, the veneer is superimposed on the door and recall from the center to the edges. So that the veneer glued better, on its surface you can walk with a hot iron. It must be done carefully not to burn the surface. If, in the case of sticking, air bubbles were not removed, you can wet a little surface and make a small incision or puncture.