The beauty of natural stone is incomprehensible. Since ancient times, this building material was used when finishing the premises and furniture. You can sing about it for a long time. But there is one big drawback from natural stone - this pleasure is too expensive. Mining in career, transportation, cutting, molding and grinding are too costly processes, which only increase the cost of products. It was possible to replace it before the tree could be only, but it did not have those qualities that would increase the service life.

But scientific and technological progress presented to people the opportunity to have a cheap stone finish in their homes. This is an artificial stone, which possesses all the same qualities and properties as natural, only its price is many times lower. We also will be interested in this article - the manufacture of artificial stone countertops with their own hands.

What is an artificial stone

Let's start with the fact that the artificial stone is primarily a solution from various ingredients, which necessarily includes a binding material. It is after it is frozen that the composite (and in a different solution cannot be called) becomes durable as a stone. Therefore, the classification of the stone solution is divided according to the binding element used. Currently, it is also used or cement, or different types of resin.Cement base for artificial stone used for a long time. If you correctly comply with the proportions of all components, then the product will be very durable. As fillers, stone particles (granules) are used for this. After pouring the solution in the form and solidification, it is grinding the stone surface to a mirror state.

It should be noted that the cement countertop is a lot of weight, however, the last century. Today, such table covers are no longer manufactured. They are too heavy, it is long happening to dry out the product, and on the shock loads such countertops did not pass the test.

The second category is products from acrylic. What can be said about this option? Let's start with the advantages.

- Low weight, can even be said, small in comparison with cement.

- Decent strength, not inferior to cement structures.

- Moisture resistance at 100%.

- The life is practically inconsistent if the product is properly operated.

- The widest range of colors, which is provided by pigments.

- Artificial stone is not a radioactive, which cannot be said about natural. In any stone, there is always a small dose of radiation background.

- Speaking about repairing countertops from artificial stone with your own hands, it should be noted that this process is completely simple. Knowing the rules and nuances of repair work, the countertop can be put in order at home without spending large money.

Everyone is well artificial stone, but it also has its drawbacks.

- The acrylic countertop does not withstand large temperatures, so it is not recommended to put hot dishes on it. Maximum it can withstand temperatures up to + 180c. By the way, materials with polyester resin are withstanding the temperature to + 600c.

- Depending on the resin-used product, after a few years of operation, scratches may be fragmented or they can be formed.

Article on the topic: holder for curtains - how to fix these devices

As for the filling of artificial stone, the granules of any stone rocks can be used here.

Making countertops

There are several technologies for manufacturing countertops from artificial stone. But in any case, everything starts with the preparation and definition of the shape of the product, which should fit into the kitchen interior. That is, you need to take the paper and sketch sketch on it for a stone countertop. The form is determined by the taste preferences of the host of the house, and the dimensions are determined from the dimensions of the kitchen space. All this and must be transferred to paper.

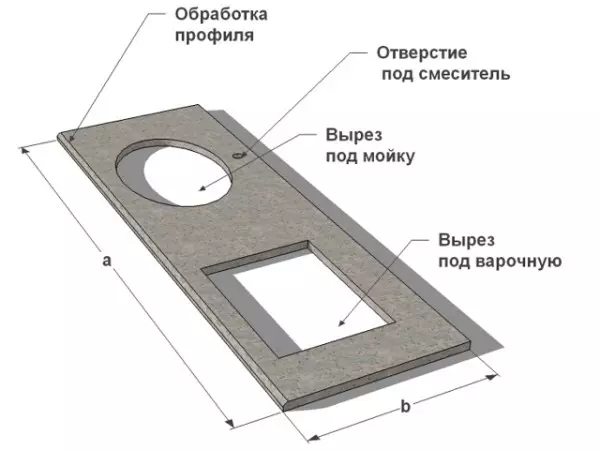

Of course, the easiest thing is the stone countertop to make rectangular without any bends and rounds. Even novice homemade master will cope with it. More difficult, if the form of the product is diverse with different sizes. It is not easy to also make a tabletop of a P-shaped structure, in which it is additionally necessary to make holes for the sink and a cooking panel.

Therefore, it is necessary to begin to make a tabletop from an artificial stone with their own arms. The optimal width is 60 cm, the length depends on the collected furniture on which the tabletop will be installed.

Making acrylic stone

Let's start with the fact that there are two versions of this type of artificial stone on sale. These are ready-made sheets with dimensions of 3.66x0.76 m, 3-12 mm thick, and the so-called liquid stone, which can be formed by itself.

Consider the first option. So, in front of you, the sheet that needs to be adjusted under the sketch dimensions is pre-applied by you on paper. It is very important to move to the stone and the size of the table top. Now the cutting diamond disk should be carried out along the lines of incisions, giving the preparation of the semi-finished product, but almost with the exact size. If you need to drill holes in the worktop, then it is necessary to do it now.

Now with cutter (good quality), it is necessary to seet the ends of the obtained billet. It also concerns the ends of the cut holes. Of course, the thickness of the sheet in this case plays an important role. But even 12 mm is not a guarantee of high strength, because the installation on furniture racks will be obtained, which can cause a break. Therefore, under the table top it is necessary to establish the basis. For this, the moisture-resistant plywood is usually used, because the kitchen is wet. It is not necessary in this case to use materials such as chipboard or fiberboard.

Now from the plywood sheet it is necessary to cut exactly the same products with holes and sizes. After that, both materials are glued together with a two-component adhesive composition and are tightened by clamps. In such a state, they should go around 7 hours.

Attention! If a thick sheet of workpiece is used for the production of countertops, then the basis can be made not solid. To do this, you can cut the strips with a width of 7-8 cm, which are evenly distributed and glued to the back side of the acrylic stone sheet.

Please note that from the end of the front side and from the sides will be visible to plywood, so it must be closed by strips of artificial stone. What they are cut from the same sheet. The width is determined again with taste of preferences, but there are standard sizes - 3-4 cm. Rear end will need to close the finished profile or plinth. All these elements are glued in their places in the same adhesive composition. Contact glue carefully. He dries quickly, so here you have to sleep, but with due care.

Article on the topic: Homemade folding knife with their own hands (Guidelines, step by step, photo)

And one moment. If a M-shaped countertop is made with your own hands, then you need to install a strip of plywood directly along the connection line at the junction of two parts. It will play an additional rigidity edge, which will increase the strength of the product.

And the last final stage is a grinding of plywood stone countertops with their own hands. Make it can be grinding.

Liquid stone manufacture

What materials are needed to prepare a liquid stone at home. Let's list them.- Acetone as a solvent.

- Hardener, it is a resin.

- Calcinite is calcium soda or calcium nitrate, which dissolves well in water. In essence, this fertilizer.

- Epoxy gelcoat is an elastic pigmented type material. It is made on the basis of resin.

- Stone fillers.

In principle, the base of the liquid stone is gelcoat, fillers, hardener. The proportions are: gelkout about 60%, hardener up to 40%, the rest of the filler. When mixing should turn out a liquid pasty substance. Now to the question, how to make a countertop of artificial stone? There are two technologies.

The first is that you first need to prepare a template with form and sizes. To do this, you can use Paneur, OSP, chipboard or DPV. Liquid material is applied with a layer of 2-4 mm. After drying, it grinds on the front side.

The second technological production of table tops is called reverse. It uses different materials that are not in the previous list, but they are necessary when filling.

- You need to make a pattern of plywood sheet, you can use chipboard. The main thing is that the selected sheet is not thin, because the strength of the material is necessary here to withstand the weight of the poured solution. The size of the template must be greater than the original by 5 mm on each side.

- Cut from plywood strips width 5 cm, and glue them to a template around the perimeter using thermocons. Put them on the edge.

- If there are holes in the worktop, then they need to be cut and pasted all the same strips on the edge.

- For the tightness of the design of the shape of the side and the template, you can deceive with plasticine.

- Now the resulting form from the inside should be cooled with wax or any other separation composition.

- Everything is ready, you can pour a liquid stone.

- Without half an hour withstand, then superimpose fiberglass. It will perform the functions of the reinforcing frame to increase the strength of the product.

- Now it is necessary to pour the soil on top. This is a mixture of calcite (80%), hardener (1%), resins (8%) and pigments.

- From above, the primer layer must be laid another pattern, with which it is evenly distributed on the bottom. That is, it will have to be cut in advance from the plywood sheet. Optimally, if there is a small cargo on the upper template, it will squeeze the excess soil, which should be immediately removed.

- In such a state, the design should chase one and a half hours.

- After that, the goods and the template are removed, and the upper surface is grouped to the mirror glitter.

Article on the topic: Bathroom renovation. What can be saved on?

Some masters recommend soil to fill in two layers. This will increase the strength characteristics of the table top made from the liquid stone with their own hands. At the same time, the first layer is poured at the rate of 5 kg per 1 m² of the surface, the second - 3 kg. Consider that the liquid stone itself will leave 3-4 kg / m².

Made in this way of tabletop is much stronger than on the first technology. And accordingly, they have a longer service life. Of course, this operation takes a lot of time, but it is worth it.

Repair countertops from artificial stone

In principle, repair countertops from acrylic is made on very simple technology. For example, if a crack or scratch appeared on the surface. This will require all the same glue that plinth and flights are glued to the product.

First of all, it is necessary to calculate the crack, that is, increase its width. Then the glue composition is poured into it, which is grouped after drying. All, repair is completed.

If bloating or spot appeared on the surface, then this area must be cut to a depth of 1-2 mm. This is done with a cutter planted on the Bulgarian. Then, from a piece of the same finished liquid stone, a smaller piece is cut out, in shape and sizes coinciding with a cut area. Now this piece should be glued to the cut-out area. After soaring glue, the border of the patch should be squeezed, fill them with glue composition, and after drying it.

Conclusion on the topic

It should be noted that the manufacturing technology of the tabletop from this material is not the most difficult in mind the simplicity of the product itself. For example, make a sink from an artificial stone with your own hands much more difficult. After all, this is already a bulk design that requires the use of a more complex template. To that rounding washing create certain difficulties in their formation. Therefore, for obvious reasons, it is made only from liquid stone.