How to make the door from the lining, know professionals. They recommend using the following tools and materials for the manufacture of the cloth under consideration:

Doors made of lining will look good in the premises of those covered with the same material.

- boards;

- Fasteners:

- door furniture;

- primer;

- saw;

- drill;

- a hammer;

- level.

Step-by-step instruction

The door is made according to the pre-prepared drawing. To do this, it is necessary to determine the parameters of the future canvas. The height of the standard design is 2 m, and the width is 90 cm. Builders recommend to reduce the indicators (to reduce heat loss) to 180x180 cm. If the door is made for the bath, then a small window is made in a canvas from the wall panel.

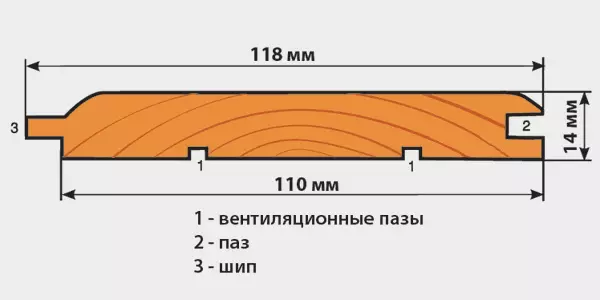

Lining scheme.

A good frame installed in the door opening is used for suspension design. Otherwise, the framework makes it yourself. This will require a ram with a cross section of 100x100 mm, hammer and construction nails. After installing the box, measurements are measured. The door made of lining is manufactured taking into account the data obtained.

Pre-apply wood. The weight of such a design will be significant. A more expensive analogue is considered a cloth from plywood sheets. Builders recommend making the door from the lining, combining a slight weight of the product and low financial costs. Rama is made of boards with parameters 100x300 mm. The central part is presented in the form of a lining. The required material can be bought in the construction market. When choosing boards, preference gives well-dried wood. Told treated with oil (one side smooth).

Manufacturing technology

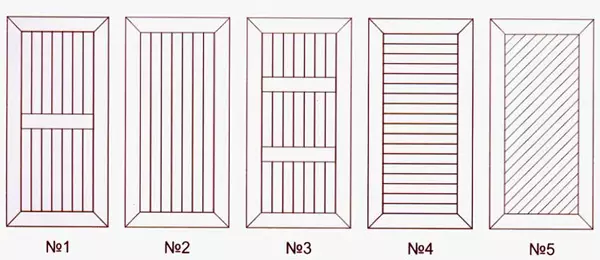

Variants of drawings when finishing with lining doors.

To make the door of 180x80 cm, the workbench will be required. The lining is purchased minimum thickness. With the help of electric jigsaw or saws cut 2 boards (180 cm). With their end side, appropriate grooves are made (the depth is 40-50 mm, and the width is 10 mm). Vertical doors are ready.

Article on the topic: an extension of the veranda to the house

Then three boards are prepared in a similar way (length 68-70 cm). By making an indent to 4-5 cm, the door is stepping at a depth of 10 mm (from below). The board is inserted into the grooves of vertical elements and is fixed with nails.

The next stage provides for the cutting of the clap length of 68-70 cm. Total will need 40 slats. The material is inserted into the groove of the vertical elements of the door, fixing them with nails. Preliminary assembly is completed using the 1st short pine board. Wood is inserted into the remaining gap. A short pine board is inserted into the middle of the design (for a screed).

Then the installation of accessories including lock and loops. The door from the lining is hanging on the frame. If desired, the plywood shield is inserted into the groove. Then the design is rummed by straps. The resulting canvas is ground, covered with varnish or paint.

Sliding design

From the wallboard you can make sliding doors for the cabinet.

To make sliding doors from the wallpaper for the wardrobe, you will need to make a frame. To do this, we use the board with a cross section of 100x20 mm. The size of the canvase depends on the parameters of the cabinet. When performing this work, it is taken into account that the door width is less than the width of the cabinet section. Folds must close the flashes.

After buying a material, it will take some time on its drying. Products that have passed chamber drying have high humidity. Installation of such elements without additional drying will lead to a warping and cracking of the canvas. If the design is stained, then an alkyd soil is applied to the front of the product. After thorough drying, the lining and the stream board are painted. You can apply for these purposes by varnish or lustering composition. After combining slat, the design should dry well.

It is forbidden to deform the door to the complete drying of the glue.

The lining is cut into the corresponding length. The planks glue between themselves (to give a sliding structure of a certain rigidity). To do this, you can use PVA glue. The front side of the door is mounted crossbars from a stream board (with a cross section of 100x20 mm). The wood is attached to the wood (bottom and top). If necessary, the bar is loaded and stained in the desired color. Similarly come with clapboard.

Article on the topic: Cozy balconies: sliding systems with their own hands

Self-tapping screws are used to fix the last material. Fasteners are tightened from the back of the product. Pre-make a hole. Otherwise, the main product can give a crack. Vertical elements made of a straw board are decorative. Sliding doors made of lining are ready to operate.