The lambrequins are three species. You can highlight soft, rigid and combined lambrequins. Sure hard lambrequen to make the interior of the room completed. The dimensions of the lambrequins of any kind are determined by the ceiling height. Sew a hard lambrequin can be standard length, which is about 1/6 of the total size of the curtain length, which will make the lumens of the winds perfect.

Hard lambrene is a decorative element of a curtain, which sews from hard tissue.

Hard-type products are a tissue strip, which should be duplicated by another cloth with the greatest density. Material for duplication can be different, for example, a dense pleated cloth, phliselin or other lining, which allows you to excellently hold the shape of the panel.

It is possible to fix the products using chapels on the bar in front of the eaves itself. Soft lambrequins always have folds attached to a machine string. Sweating folds wear the name of the Swag, the dimensions of which determine the amount of tissue consumed.

How do you like hard lambrene

By the method of sewing, the lambrequins are divided into complex and simple.

For lambrequin decoration, you need beads.

The first combine soft and tough types. The combinations data are more often made of softer materials. When selecting ready-made purchased products, it should be focused on the main color of the curtain material.

If you start learning to sew the lambrequins of a hard type, then it is better to make it better for the kitchen. This will not require the invention of special templates on a specific design. The lambrequined window of a hard-style type called Bando will be ideal for any room, starting with the children's and ending with the working office.

Decoration of products is fringe, cords or flowers from different fabrics. To make it yourself, you will need tools and materials such as:

- Base Bando in finished form - 45 cm wide, you can take the adhesive tape.

- Iron.

- Decorative finish.

- Sewing machine.

- Scissors.

- Sticky tape.

How to perform stages of sewing

You should follow the instructions:

Article on the topic: Separation measurement

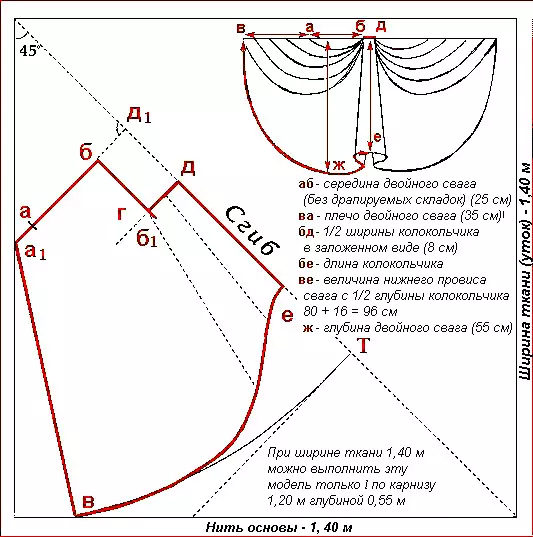

Pattern of rigid lambrequin.

- Enter a special pattern prepared in advance to cut the Bado base.

- Turn the cloth with a warm iron.

- The tissue on the bandana is glued with a warm iron.

- Excess fabric from the edges is cut into 5 cm.

- Next, the fabric is applied to the lining.

- With the help of a pin, three sides should be pierced.

- From each edge of the bandage should be strained one centimeter.

- Next, the excess fabric is cut.

- After that, the product is straightened on the front side.

- The top edge is rotated by the front side, stretching it, challenge the pin.

- After that, it is necessary to push the Velcro Velcro with a tough side to the eaves.

- After that, the velcro is fixed with a machine line.

- Next, it is necessary exactly next to the sticky ribbon to enhance the material.

- After that, the sticky tape is twisted and pierced by a pin.

If this method of performing hard lambrequin is too complicated, the panel is made without a special lining, cutting off exactly the tissue where the edge of the adhesive basis passes. With the help of an adhesive gun, the finishing material should be strengthened throughout the edges. The finish can be a cord, braid, fringe.

In the process of manufacturing rigid lambrequin, you should adhere to several simple stages:

For sewing, the lambrequin will need a roll of dense fabric.

- Make the usual pattern. At first, for the template, the entire dimensions of the future lambrequin bandoon are removed. Previously, it is necessary to accurately decide how specifically the product will look, break all the cornice. Bando shape can be strict or have figures and teeth.

- It will take to buy a frame, that is, the ready-made product of the band-pro-rolon. It is a dense fabric, which is phlizelin or dublerin, possibly material for decor.

- On the pattern, it is necessary to cut the frame, given all allowances on the seams (5 - 6 cm from all sides).

- Prepared pieces of fabric need to be glued to the band panel (you can use the steam generator, which is ideal for applications).

- The bands of the bandanda are processed by a velcro, which passes with an indentation from the edge of about 3 cm so that it is invisible.

- The lambrene decorated should be placed on a special cornice where it was planned.

How to independently sew a figured hard lambrene

All sizes of the future lambrequin move to a dense tissue.

Article on the topic: How to Clean the dirt paper wallpaper

Pre-relate to the size of the future product from the width of the room. All sizes are transferred to the panel of wood or dense material, where the figured pattern and sidewalls are indicated. Next is the special lining and the gasket of the same form with a breakdown on the seams of 1.5 cm along the edges of the template. To make rigid lambrequin yourself, you will need:

- Towder made of wood.

- Special material for tosing a template and lining.

- Rings sewn to lambrequin.

- Cord and braid.

- Special glue for fabric.

The phased work on cutting includes:

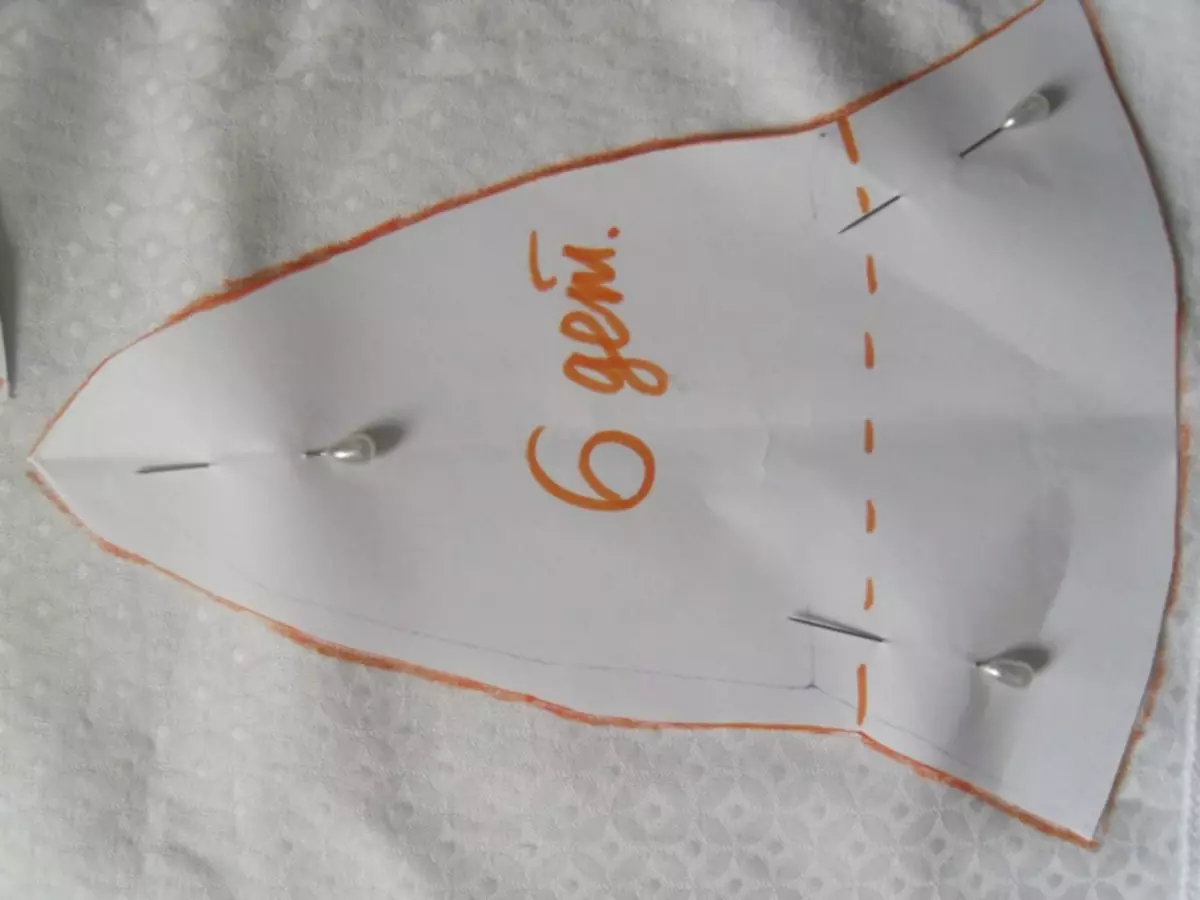

Strengthening the tissue on the rigid base of the product is performed using a pin.

- Strengthening the gasket tissue. The product is placed on the laying, observing it with the middle. After it is necessary to cut its edges where the allowances are passing. Make all cuts to make it more convenient to convert the edges of the gasket for all angles and roundings. After that, the bar from the edges and the material is lubricated with special glue. All edges are stuck, strongly pressing with their hands. Similarly, it is necessary to attach the gasket and from the side of the product.

- The implementation of the cutting of the product from the main material. It should be cut, adhering to the share thread. The panel is placed by gasket down from the origin of the base material. After that, it is necessary to cut the cloth, leaving the seam allowance equal to 3 cm, by a total perimeter. After that, similarly make the tissue and for each of the sidewalls.

- Strengthening the tissue on the rigid base of the product. Cuts should be made on the fabric, as well as on the gasket, to bend all the edges on the roundabout of the prepared gasket fabric. Details must be made using a pin, stretching the same cloth, laying on the base of the panel. Cut corners are glued to the base and padding tissue, then stroke the hot iron. With the edges of the lateral parts come in the same way.

The main stages of the manufacture of lambrequin

The inhibitory circuit of the front panel of rigid lambrequin.

- Implementation of the preparation of the material as a lining for the panel. The required lining fabric is laid out on the table for the front of the product. After that, they make special cuts on all roundings, making each edge inside out 2 cm, then everything needs to be treated with an iron.

- Strengthening lining on a rigid panel. The lining must be put on the front side up from the back of the front of the panel. The edge is treated with the help of secret stitches. In this case, one end remains free, that is, it does not sew it. Similarly, all sidewalls are treated, leaving each front edge of the panel open.

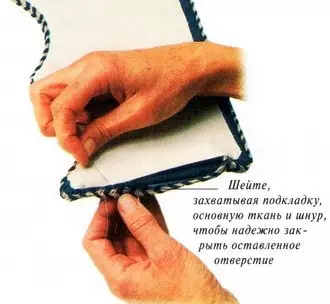

- Edging of the product, that is, its front panel. The length of the edges of the front panel is determined, the cord is cut down the required length. Start where there is no line, refueling the ends of the cut cord under the lining of the product itself. Select the cord to the edges of the front with the help stitches. Sew the unprocessed part of the lining, and in the end sewn to the cord panel.

- Effect of edging sidewalls. First, determine the length of all edges of the side parts, including the upper slice, rear and lower. Next, you need to measure and cut off the cord of the suitable length, which is sewn to each of the three edges. Ends should be filled with inside, and the holes are closed, like the front panel. Next, sew lining along the front edges.

- The sewing of a special rings on the lambrequin for its attachment to the eaves. Small self-tapping screws are strengthened on the top of the plank.

- Next, sew rings on the product from its back and on the side items that are below the cord. The distance between rings and self-drawing should coincide. After attaching the rings on the panel they are hung on the bar.

Article on the topic: Krepim Plasterboard on the wall and ceiling with glue

Since it is necessary to make rigid lambrequen, then it must be used to buy a sticky tape (Velcro), as well as glue moment. Fix rigid lambrequins can only be for a flat surface. The tape of the sticky side is glued to the outer side of the eaves, and the soft part of the tape is sewn to the lambrene where its outcomes.

If the eaves no desire to hide under the lambrene, as it is very beautiful, then the sticky half of the tape is glued to the invalid side of the baguette having a luxurious view. The soft half of the sticky tape sew from the front side of the lambrequin.