The heating systems in private homes and apartments need periodic flushing. In apartment buildings of this work, employees of public services are engaged in the fulfillment of this work, and the owners of private houses have to do independently or hire third-party specialists. During operation in the heating system, various small particles are falling, which are settled in batteries, pipes and a boiler. Without flushing, these particles will accumulate and compact, which will lead to the blockage of heating and pipes, water circulation disorders in the heating system, the output of the heating system. To prevent all these problems, a periodic washing of the heating system is necessary. Before rinse the heating system with your own hands, be sure to learn the rules and features of this work.

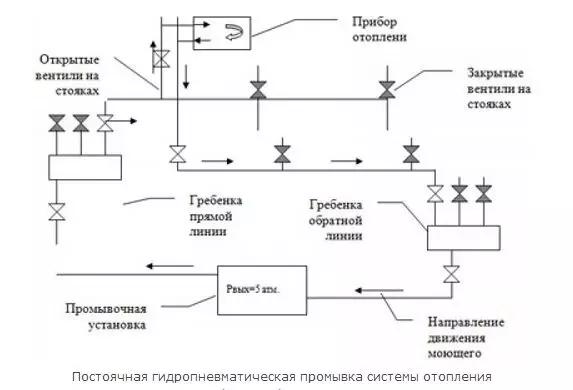

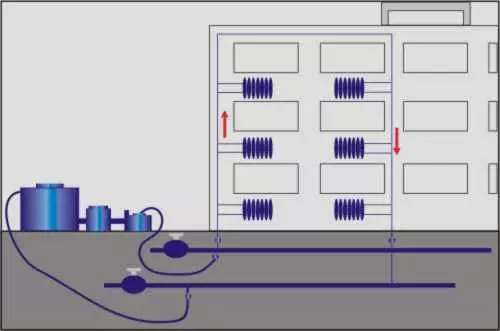

Diagram of the permanent hydropneumatic washing of the heating system.

Washing pipelines of the heating system: why is it necessary?

To rinse the heating system correctly, you need to know why this washing is performed.

The technology of flushing pipelines of the heating system is quite simple, so, observing certain rules, you can do everything yourself.

Washing pipelines and other parts of the heating system are needed in cases where the heating system that has not been washed for more than 5-10 years has low energy efficiency, which is associated primarily with a large number of magnesium and calcium salts on the heating pipe walls. It is known that a layer of sediments with a thickness of only 1 mm reduces heat transfer by about 10%, which immediately affects the overall energy efficiency of the system of heating and electricity consumption. Moreover, the overbring of pipelines of the heating system by scale and sediments leads to a drop in temperature in heated rooms.

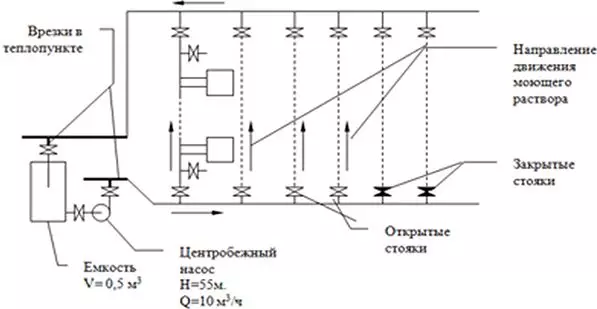

Standard technological diagram of washing the heating system.

In case of refusal of timely flushing of pipes, the heating system consequences can be simply catastrophic. It should be understood that the flushing of pipes of the heating system is a mandatory service procedure. This technology is designed to maintain the heating system in proper condition for a long time. High-quality and long-term operation of the heating system is impossible without periodic flushing, which, of course, should be performed correctly.

In case of refusal of timely flushing of pipes, the heating system is possible and the destruction of expensive equipment of the thermal point is possible, the likelihood of different emergencies is not excluded, until the defrost of the heating system in winter, which ultimately leads to idle system of heating and significant financial losses, noticeably diminishing mechanical destruction processes Heating pipes, etc. That is why the rules of operation of the heating system regulate its mandatory periodic verification.

Why are deposits formed on the walls of pipes of the heating system?

The main conductor of heat is water. It is she who represents the main reason for the contamination of the heating system. The sludge, formed by the salts of hard water or the smallest particles, becomes sculpt, solid sediment. Singing on the inner walls of pipes of the heating system, scale significantly reduces the efficiency of the heating system.

Article on the topic: Mercury Counters: species, characteristics, features

Scheme of washing the heating system.

The thick layer of scale is characterized by high thermal insulation properties, i.e. prevents heat exchange. In addition, the scale intensifies the mechanical processes of pipe wear and other elements of the heating system.

That is why the rules of operation of heating indicate the need to periodically carry out various prophylactic work, the inalienable component of which is washing.

Washing the heating system: how to find out what time has come?

There are a number of features, according to which it can be understood that the time of washing the heating system has come:

- Heating radiators are heated unevenly. As a rule, the top of the battery is warm, while the bottom is cold;

- When heating the heating boiler, characteristic crackling is heard due to a thick layer;

- Premises warming up much longer than this required before;

- reduced power of the boiler;

- the costs of the coolant are significantly increasing;

- With hot battery pipes remain cold.

The flushing rules of the heating system provide for the possibility of applying chemical and physical cleaning methods. Physical methods include waterproof and hydropulse flushing, which require the use of special equipment - compressor. The chemical method of washing is the use of various drugs dissolving the deposition of the sludge and scale.

Diagram of chemical flushing pipes.

To rinse the heating system yourself, prepare the necessary tools:

- Construction Key;

- chisel;

- spanners;

- basin;

- scrap;

- Funds selected in accordance with the washing method (compressor or facility to remove scale).

Flushing of the heating system with a water-pulsing mixture and biopreparations

The basis of this method is the purification of heating tubes with a pulsating mixture of water and compressed air. Rules and technology are quite simple. Compressed air is supplied to the heating system, whose twigs with water raise salts, corrosion, nagar, sand and other sediments. Further impulse air supply displays sludge from the pipes of the heating system, not allowing it to settle on the walls.

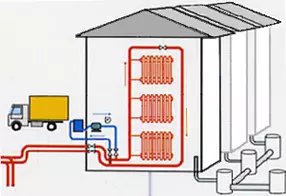

Observing the rules and technology of such a washing, you can extend the life of your system for 20 or more years. This method allows you to clean the thermal network for any period of the year without dismantling the risers and batteries.

Standard diagram of chemical flushing pipes.

Washing pipes of heating systems by biopreparations is a highly efficient and environmentally friendly method, the rules and technology of which include the introduction of microbiological drugs into the heating system.

Circulating through the pipes of the system, biological preparations split organic, oily-mud and solid deposits. The rules and technology of this method do not provide disassembly or shutdown. Another positive point in this case is the safety of modern cleaners for old systems.

Washing the heating system through pneumohydrogen and chemicals

This method is commonly used to flushing old heating systems. The rules and technology of performing such work provide for the impact on the drum hydraulic system, which extends through a system at a speed of 1200 m / s and punches the brackets from screaming and sludge. The walls of radiators and pipes, while not destroyed, because They have no more than 2% of the total strength of the wave impact, and the remaining 98% fall on various deposits, which are destroyed and output through a flexible sleeve in the sewer system.

Article on the topic: How to measure the entrance door: Selection of the door canvase

Observing the rules of the hydrotreaty, it is possible to significantly reduce operating costs, because There is no need to replace pipes and radiators.

Various chemical preparations allow cleaning and rinse pipelines, risers and other nodes of the heating system with reagents based on organic and inorganic acids. This method of chemical flushing is considered one of the most economical, and covers not only surfaces, but also hard-to-reach sediment places.

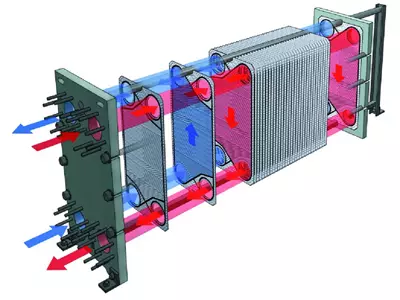

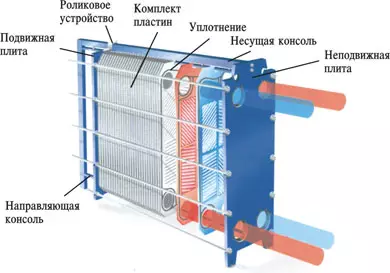

Scheme of heat exchanger device.

In the case of applying such reagents, it is very important to follow the rules for their use, which are usually given on the package. Technological means completely eliminate traces of scale and corrosion in the heating system for 5-10 hours.

However, the rules for using such funds indicate the need to estimate the state of heating equipment. The physical condition of the radiators and pipes, the degree of wear, the wall thickness - these parameters must be thoroughly examined for the risk of damage to their chemical reagents, the composition of which, as a rule, includes hydrochloric acid.

Consider the fact that even performing all the rules of flushing the heating system, you can not always achieve the desired result. Sometimes, because of particularly large contaminants, a comprehensive cleaning is needed, the rules of which suggest the use of several different methods.

Features of the collapsible washing of heat exchanger

If the heat exchanger is very polluted or completely failed, a collapsible flushing can help. The rules and technologies of the collapsible washing are quite simple. It is necessary to disassemble the heat exchanger, remove all the plates, soak them in a special solution, rinse each plate manually, insert the package of plates into the heat exchanger. After that, the heat exchanger is going and pressed.Observing the rules of this work, you will receive many advantages:

- The collapsible washing of heating guarantees the highest quality;

- Any contamination is eliminated;

- Everything happens visually, and you can see the whole process of work.

However, there are disadvantages that will not be avoided, even observing all the rules of work. So, if your heat exchanger worked for wear, in critical conditions, or the life of rubber seals ended, it is possible to change the heat exchanger sealing, which will lead to an increase in the cost and period of work.

As a rule, the above-mentioned heat exchanger technology mentioned above differs only in choosing a specific method of cleaning the device plates after its disassembly. Several main methods are used:

- In the case of collapsible flushing, it is sometimes possible to remove contamination with a jet of water from a special high-pressure apparatus;

- If there are more serious deposits, you first need to clean the heat exchanger plates from the top layer of sediments using a high pressure apparatus, then soak them in acidic solution, and then cleanse them again when the high pressure apparatus is rolled.

Article on the topic: We produce balcony glazing in the house of the P-44 series or P-44T

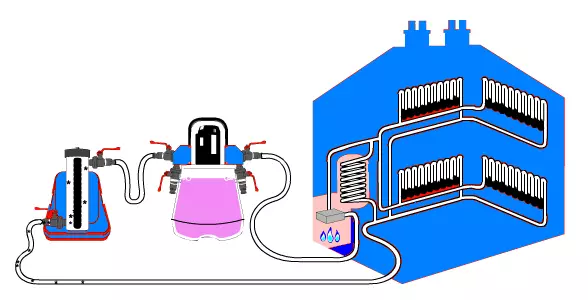

Features of the non-bleed washing of heat exchangers

For the prevention and renewal of the operation of heating systems, a non-bandwash is used, the rules of which include the use of special equipment intended for imaginary flushing. This method is used both for collapsible and soldered heat exchangers.

Among the disadvantages of this method, it is possible to distinguish the fact that if the heat exchanger is clogged with a variety of mechanical inclusions (particles of sludge after welding of pipelines, etc.), the impact washing of heating will not be effective enough, even if all the rules are fulfilled. And the advantage, in fact, is that it is not necessary to disassemble the heat exchanger.

The composition of the heat exchanger.

Damage chemical flushing is performed using a special device. This device allows chemical cleaning of welded, soldering or lamellar heat exchangers. Externally, it is a tank made of high-strength plastic equipped with a built-in heating element and a reversing pump. In the course of washing, for example, a plate heat exchanger This device is alternately connected to the contours of the unit through the drain holes.

Inside the device itself, in the process of operation there is a special detergent made on the basis of organic additives and orthophosphoric acid. Orthophosphoric acid is very well suited for chemical cleaning and washing: falling inside the heat exchanger circuit, it dissolves the compounds from which it consists. Along with this, due to the fact that in the washing solution for chemical washing of heat exchangers also includes inhibitors and organic additives, it does not cause any harm to the heat exchanger plates.

After the whole scale is dissolved, the detergent solution must be drained through the drain holes, and rinse the heat exchanger with clean water. After that, he is ready to use again.

This modern technology, if you follow all the rules of its implementation, has many advantages, namely:

- The ability to perform work without dismantling or with partial dismantling of the heating system at any time of the year, including in the heating season;

- The use of environmentally friendly and certified chemical preparations provides safe working conditions;

- Economic efficiency and high performance productivity;

- The fulfillment of the entire complex of work with high quality and as much as possible.

To clean the heat exchangers and heating systems, modern drugs are used capable of dissolving ferrous and carbonate sediments from surfaces of copper and steel alloys, and the inhibitor existing in their composition prevents the aggressive effect of hydrochloric acid. The active substances in the composition of the cleaning agent accelerate the flushing process, which allows you to quickly remove even hardly soluble and dense sediments. The dispersant prevents the re-deposition of washed sediments (especially in places of circulation), and the anti-inflation component does not allow the working solution to be recycled and prevents the formation of the so-called. "Dead zones", allowing you to completely clean the surfaces of the heating pipelines.