The world produces a huge number of different floor coatings, which are successfully operated by the owners.

Recently, the tendency of increasing demand for bulk leveling mixtures has been observed, with which the flooring is aligned and made it elastic and durable.

It is the polymer flooring for sex that the concrete base aligns the concrete base and creates a thin protective layer that prevents moisture ingress.

Features of the composition and varieties of polymer coatings

Paul quality depend on the material from which they consist

There are several varieties of polymer flooring for floors that have their own separated scope.

At the moment, polymer coatings can be classified according to the following criteria:

- the thickness of the leveling layer;

- chemical composition of coating and difference of binding elements as a whole;

- The structure of the outer layer.

Currently, the construction market is tightly filled with various variants of polymer coatings, which in most cases differ from each other by using binding elements.

As a rule, different manufacturers apply various compositions:

- polyurethane;

- polyester materials;

- epoxy;

- coatings using polyurea;

- methyl methacryplants.

It should be remembered that, despite the different thickness, there is a wide variety of connecting elements.

All polymeric concrete floors are effectively aligned with black floorings, successfully fit into the interior of any room, and are also an indispensable variant of sex flooring with a limited thickness of the finish cover (doorways and built-in wardrobes limit the height of the floor layer).

Epoxy connecting compounds for bulk sex

Epoxy floors are distinguished by special aesthetics, but are not durable

This connecting composition has a wide scope of application. The polymer coating of this species is the most common variety of floors and is widely used in apartments and private houses, thanks to the affordable price for this product.

Article on the topic: The height of the inlet door threshold: installation of wooden and concrete thresholds

This type of flooring is distinguished not only by continuous advantages, it, like many other sexual materials, has a number of disadvantages, the main of which is possible evaporation of the main binder, which leads to fragility of the coating and some external changes. The use of such bulk floors is not recommended for premises with increased permeability and large sanitary requirements.

It should be known that Quarpentic sand in certain proportions are added to the composition of the polymer coating with a binding element in the form of epoxy resin, which makes the flooring sometimes not enough strength and resistance to temperature drops.

Methyl methacrylate binding compositions of polymer coating

Methyl methacrylate floors are quickly mounted and dry

This layout is a reliable method of alignment and organization of coating. The use of methyl methacrylate compounds in the composition of a certain variety of polymeric floors allows to organize a coating for the shortest possible time.

These coatings can only be deposited by specialists.

Experts argue that with the use of this mixture, cover is created for 35-50 minutes. Moreover, work can be produced at any temperature, but this polymer floor covering cannot be organized independently.

To perform the fill of this type of bulk sex, it is necessary to invite specialists who possess specialized technique for the process, since in a short period of time the entire mixture must be evenly distributed over the surface.

The creation of flooring is a rather toxic hazardous procedure that requires the use of personal protective equipment.

The composition of the polymer coating with this binder element is often added mineral fillers, which increase the strength of the product, give hardness and resistance to mechanical damage.

Polyurethane bulk floors

This type of polymeric floors requires mechanized styling by professionals, as it has sufficiently large requirements for roughing. It should be as purified as much as possible from the garbage (this composition is poorly in contact with foreign materials in its composition). For details on how polyurethane mixtures are poured, see this video:Article on the topic: Methods for creating a cupboard decor with their own hands

The underground before the fill of the bulk coating should have a certain humidity, otherwise all the shortcomings may affect the operational qualities of the outdoor material.

Polyurethane floors can be poured at any temperature, and they have excellent resistance to atmospheric drops and small mechanical impacts (scratches).

Polymeric polyurea-based coatings

Indoors with a large humidity floor from the polyurea is optimal

This flooring has the greatest universality of all above the above options. It is used in conditions with high humidity.

The polymer floor of this type can be stacked on any surface (concrete, metal, wood, wood stove), including on unprepared.

The strength and resistance parameters for various impacts in the polyuctural floor are always "at height", as well as its appearance.

But, despite all the advantages of the material, it is not so often exploited, as it has a considerable price and fills exclusively using special equipment, which is not every customer can afford.

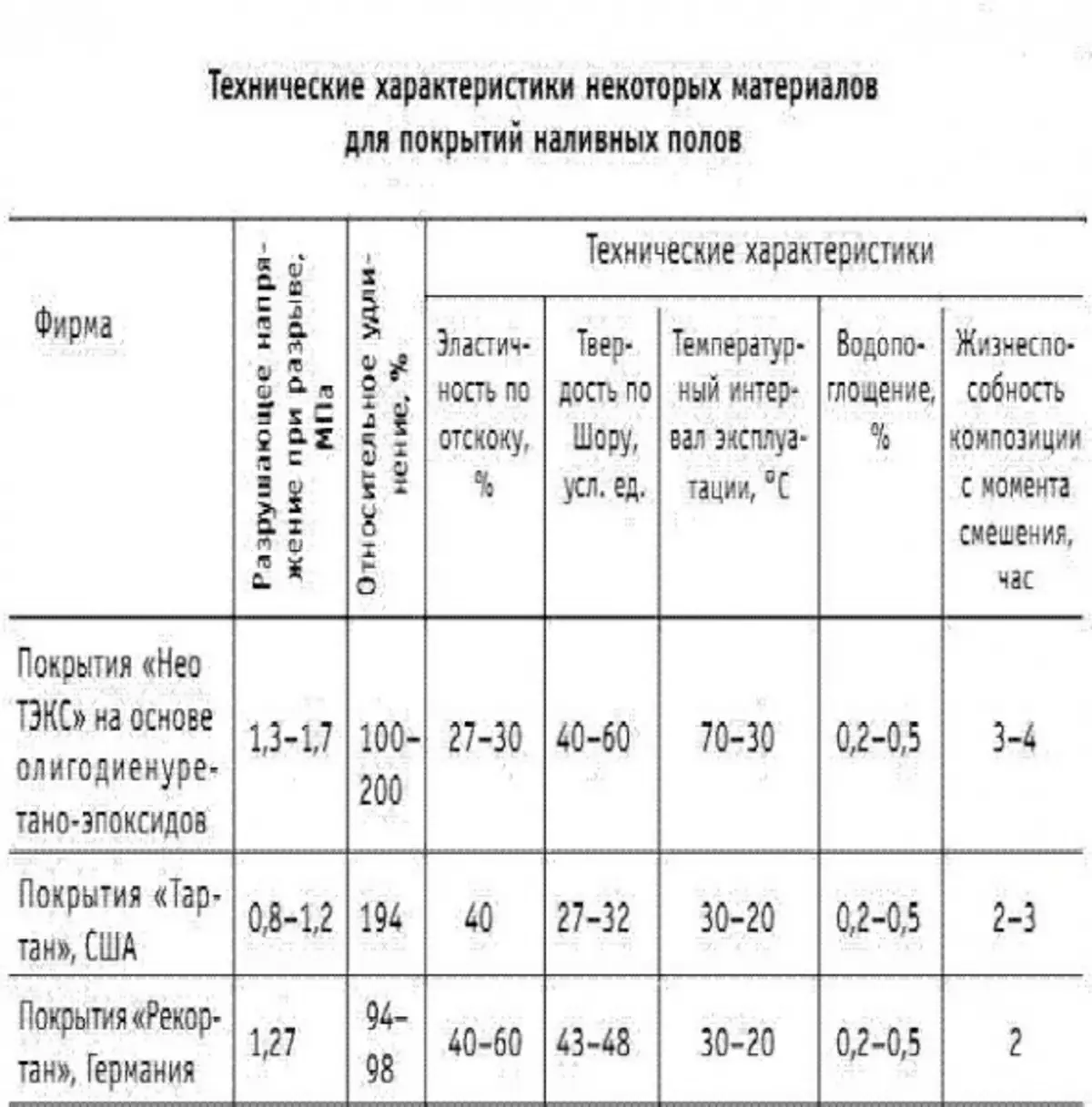

Some comparative characteristics of bulk polymer coatings of various manufacturers can be seen in the table.

It should be known that the cheapest variant of the polymer floor is the composition with polyester binding elements. It is poured independently without the use of special equipment, it has an attractive appearance, but poorly tolerates temperature differences.

As a result, it may be collapsed, so such a flooring is used in rooms with the possibility of constant temperature control.

Polymer coating thickness for floors

The thickness of the floor polymer flooring can be different. It is according to the thickness parameter that there is an additional classification of bulk floors:

- Dusty formulations;

- painting polymeric materials;

- polymer coatings of the thin layer;

- Flooring with a thickness of 1.5 - 3 mm;

- Durable floor system 4-6 mm thick.

Dusty polymer composition is a temporary protective coating. His life is usually not exceeded 1 year. The mixture can be poured by an independently thin layer, and quite often such a flooring is used as an intermediate version.

Apply such a polymer floor is recommended for concrete surfaces.

The painting polymer layer is a protective coating that has a direct intended purpose. The thickness of the material can reach 0.5 mm, but this layer is enough to protect the overall coating for a period of 5 to 10 years, but not for alignment. For details about the painting layer, see this video:

Article on the topic: Find out what kind of AluCobond panel

Areas of use

Thin-layer polymer coatings are represented by bulk floors with epoxy and polyurethane binding elements.

These coverings are often used for leveling purposes and have excellent operational properties.

These coatings are used in elite housing

Polymer floors with a thickness of 1.5 - 3 mm are often used to decorate elite houses and apartments. The thickness of the layer allows you to produce as leveling work and decoration, with glossy vinyl films.

Thick bulk floors are organized by the frame method. Initially, a metal or fiberglass mesh frame is installed on the overlap (from any material), which is filled with a mixture.

This type of flooring is often applied not only for private needs, but also for household premises. It has the best operational characteristics of all listed species.

It should be known that for the organization of a bulk sex, a thickness of 4-6 mm do not need to be processed and specially prepared a rough surface.

The entire coating process is done manually, which makes the installation period rather long. For details on thin-layer coating, see this video:

After reading the article, each interested reader will be able to independently choose its polymer flooring, which will correspond to individual operating conditions and the draft undercase, as well as the required external parameters.