At first glance, the design of the floor on a concrete basis is nothing complicated.

However, for the correct installation technology, it is necessary to take into account many factors that may affect one way or another for its service life.

This is a multi-layered house design element, subjected to numerous loads and exposure to the external environment, so the design of work should be taken with due attention and responsibility.

Technological requirements

The correct flooring device on the concrete plate is performed in accordance with the construction requirements and norms. They are characterized by the design features of all elements.

In addition, they must comply with the standard requirements characteristic of this situation: to be durable, moisture-resistant, wear-resistant.

By making the floor for a residential premises, you need to think about heat and sound insulation in advance. If we talk about standard technological requirements, we can allocate a number of rules characteristic of this situation.

| Characteristic | Name, technical condition | Short description |

|---|---|---|

| GOST 31358 - 2007 | Dry building floor mixture on cement basis | Properties and compositions of cement mixture. Use for a floor |

| GOST 10178 - 85 | Cement | Technical features and requirements for the material used for the screed |

| GOST 25328 - 82 | Cement for building mortar | Regulatory data relating to the composition and characteristics of the mixture |

| GOST 24640 - 91 | Additive for cement | View and method of using the additive used to fill the floors |

| GOST 7473 - 94 | Concrete mix | Formulations, manufacturing and use of a mixture on a concrete basis |

| SNIP 2.03.01-84 | Concrete and reinforced concrete design | Installation of w / w designs, Floors with reinforcement |

| Snip 3.02.01-87 | Earth construction base and foundation | Process of mounting draft floors |

| SP 52 - 101 - 2003 | Concrete and reinforced concrete design without pre-voltage of reinforcement | The process of reinforcing concrete |

| SNiP 2.03.13-88 | Floors | Constructive Floor Solution, Installation Requirements |

Designing, the choice of material and installation must be performed on the basis of the requirements presented in these documents. Compliance with standards will create a surface that will respond to all set parameters.

Among other things, it will have the following characteristics:

- A smooth and solid foundation will be created, convenient and practical for the safe movement of people.

- It will be high-quality, wear-resistant, durable.

- According to sanitary-epidemiological regulations, the foundation will be created harmless to humans and providing good conditions for living.

- The operational standard characterizes the ease of care and possible repairs.

All documents were developed by experts and engineers, so it is not recommended to neglect them.

Classification

Floors consisting of screed, insulation and floor coverings are called separate

The full analysis of the element allows you to select several categories of floors separated by purpose. These are manufacturing buildings, residential buildings, public institutions and livestock facilities.

Article on the topic: Differences of plastic windows

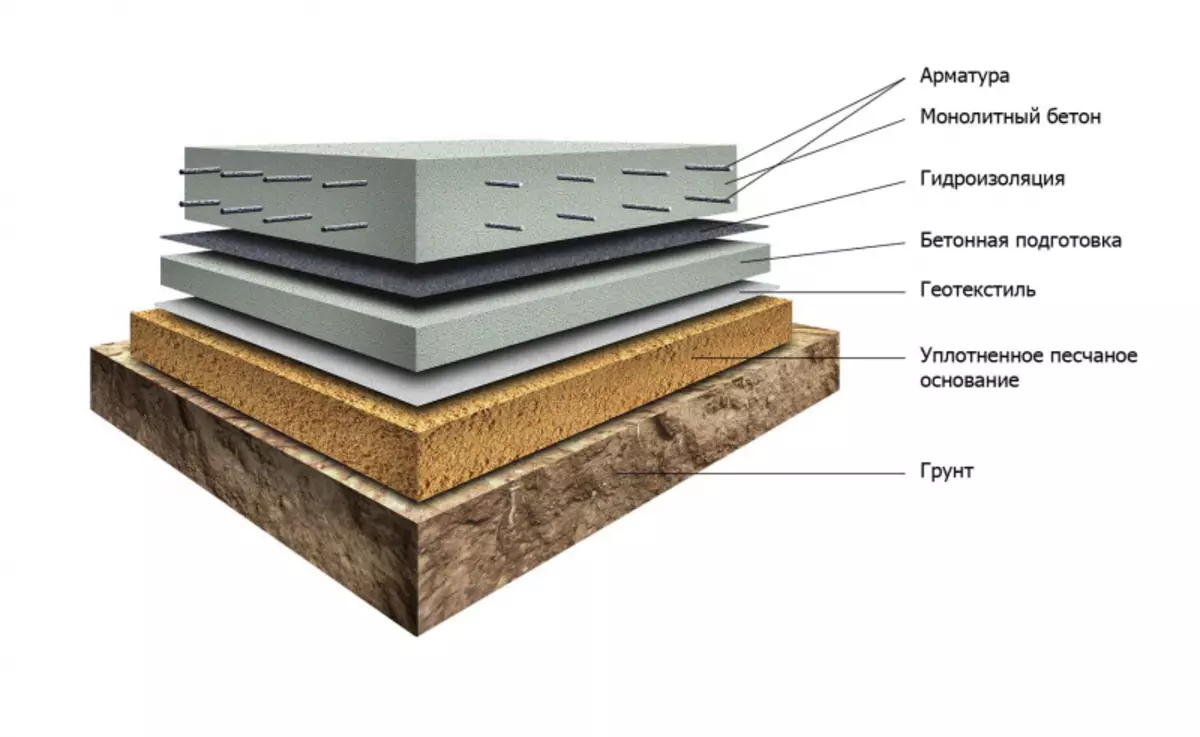

There are some more distinguishing features, first of all, separation by type: monolithic, rolled and piece. The installation of the installation site is divided depending on the location: above the heated room, the design of the flooring on the ground, according to the intergenerational overlap.

Relatively sanitary standards highlight 3 types of floor installation:

- Single-layer, manufactured from a material corresponding to GOST for heat loss and sound-resistant;

- Separate design made of a separate layer of sound insulation, screed and finishing coating;

- Empty, performed by lags (subservabuses) with styling between them and sound insulation.

Understand how to make a good floor when complying with numerous requirements, it is possible only after fully familiar with the standards.

Characteristics of concrete base

Being before the question of which sex is better, many come to the conclusion that the concrete base is one of the most unpretentious.

It exceeds a tree for many reasons, the main one of which is immunity to the formation of rotting processes.

In addition, the concrete will not scary from time to time, has a sufficiently strong surface, which is practically not afraid of mechanical impacts.

Concrete is not susceptible to loads and durable

Indicators of moisture resistance compared to the tree, too, at the height. However, it should be borne in mind that some of the disadvantages of wooden floor can be eliminated by using modern technologies.

Do not exalt the concrete surface and forget about its minuses. From constantly cold sex you can get rid of only after installing an additional source of its heating (warm floor). Based on this, the most optimal option will be laying directly on the tile concrete in the bathroom, toilet or kitchen. For residential premises, living rooms are advised to use other materials with peculiar warmth and comfort.

Laying wooden floor

Boards can be glued to concrete or put on wooden lags

To put a tree on a concrete base, you can use one of 3 methods.

Each of them is rationally different from the previous one, which allows us to talk about different advantages and disadvantages.

Methods are as follows:

- Boards are glued to concrete base;

- stacked on wooden lags;

- Stay on plywood sheets.

All methods of the floor of the floor on a concrete plate combines one - the surface preparation is performed identically, regardless of further action.

The screed must be carefully sucked and leveled.

Convex sites can be removed with grinding grinding, depressions - poured a self-leveling mixture.

After that, it is recommended to prepare the basis for laying communications passing under the floor. It can be elements of warm floors, a sewage pipeline, water supply, electric, television or internet cable.

Cuts can be made by a grinder

When processing the room with an area of more than 50 m2, it is desirable to make seams that limit the strain deformation. In this case, with the help of a grinder with a diamond circle, several cuts are made. Only after that the primer base is allowed.

Article on the topic: Store things on the wall: Organizers, buckets, baskets and other storage ideas

The antiseptic will perform the role of waterproofing and will prevent the base from the formation of mold or fungal growths on wooden elements. The most optimal impregnation option is a single-component primer mixture. Making sure that the concrete is completely dry, you can be taken for laying the floor.

The moisture content of the base plate should be no more than 4%.

Blind

Sharpen a wide board with polyurethane composition

The glued floor design is considered the most common wood installation method on concrete bases. This uses various types of compositions that differ depending on the type of board.

Wide massive is glued with a modified elastic one-component polyurethane glue. A narrow massive or engineering board is fixed on a two-component polyurethane composition.

The order of work is as follows:

- Screw the boards of the desired size.

- The adhesive composition is applied from the far corner of the room to the neighbor, the distribution over the surface is carried out using a toothed spatula.

- 3 - 4 boards are superimposed on this site and are firmly fixed. At the same time, it should be tightly pressing them to each other, it is allowed to do it with a tight belt or clins.

- After checking the laid series, the procedure is performed by the previously described method. For details on how to glue the finishing material to the floor, see this video:

The distance between the extreme board and the wall should be at least 10 - 15 mm.

Laying on lags

Lags should be no thinner 2 cm

Such a device involves the installation of boards on wooden lags, firmly fixed on a concrete base. This method can only be used if their thickness is more than 20 mm. Otherwise, they will be fed under load.

Distribute the timber on the surface is allowed according to the approved parameters, depending on the thickness of the board. To independently define this value, you can be guided by the table below.

The Lag cross section in this situation does not play the role, since their installation is performed on a solid surface.

Boards are fixed by self-drawing

Only after all calculations are made, and the material is purchased and sliced according to the desired size, you can proceed to self-install.

At the same time, do not forget to process all the wooden structural elements by an antiseptic that protects it from moisture and fungus.

The order of work is to fulfill the following actions:

- Lags are fixed to the concrete base with the help of anchor bolts. At the same time, the caps are desirable to drag into the wood. When laying on an uneven surface, you can use metal corners. They make the design less sustainable, but it frees from additional work on the alignment of the screed. In the case when communications were carried out inside the concrete slab, and the drilling is dangerous damage, it is allowed to use bitumen mastics for which lags are glued.

- A timber laid directly on concrete without alignment is once again checked by the level. All elements must be in the same plane. Detected irregularities are removed by the plane. As a result, the maximum deviation should not exceed 3 mm on 2 row meters.

- Between the extreme lag and the wall is stacked by a soft wood-fiber plate, which performs the role of sound insulator.

- The rest of the space between them is desirable to fill in thermal insulation (ceramzite, polystyrene foam, mineral wool).

- Boards are fixed on the Bar with self-draws. The use of nails in this case is not recommended, since some time after some time, the base is loosened and can begin to creak. About how to lay lags, see this video:

The feature of the design is more cost and the possibility of placing under the floor heat insulation, hide communications there.

On Faneru

Recommend to lay a phaneer diagonally

Article on the topic: paintings for interior - original masterpieces with their own hands

To lay the wooden floor on the concrete slab, sheets of plywood or OSB thick 16 - 20 mm are used.

Material must be moisture resistant. Bought plates are cut into small strips of 50 - 80 cm wide.

The laying is carried out in the diagonal direction to the location of the coating. The gaps between them should not exceed 3 mm. The strips are glued with glue or fix on a dowel of nails. After installation, the surface is thoroughly polished and cleaned from dust.

It is important that the plywood is too thin

The advantage of this method is the ability to level the surface having a height of up to 1 cm. The method of laying on the phaneer is considered the easiest and inexpensive.

However, performing installation, you need to take into account several features. First of all, it is the thickness of the sheets, which should correspond to the size of the boards, silent. In addition, mandatory processing of primer and careful sweeping.

The advantage over the method using the lag is that the height of the ceilings of the room is practically not changed.

Sometimes the opinions of ignorant people are heard that the flooring device on a concrete slab is quite complex, expensive and troublesome occupation. In fact, this is not so.

A wide selection of modern building and finishing materials allows you to solve this problem in a short period of time. At the same time, the coating will be sufficiently warm and durable, although it will be located on a cold concrete plate. About how to install plywood sheets to lag, see this video:

The only thing in this situation is required from you - accurate compliance with technological requirements and regulations related to the various characteristic properties of building materials used to perform work.