The comfort of being in the garage depends largely on whether the floor is made correctly. It should be durable, reliable, moisture-resistant. These requirements are not answering many materials. One of the most common is concrete floor in the garage. So that he performs his functions, it must be done correctly. As - in detail, on the steps we describe in this article.

Preparation of the foundation

Concrete floor in the garage do on the ground. But most often the soil itself is not sufficiently reliable and dense base, therefore a base device is required - cushion from rubble and sand. Preliminary and mandatory work - removal of the fertile layer, up to pure soil. The organic and most of the microorganisms are removed with the fertile layer, and they contain their minimum quantity.

The first stage of the device of concrete floor in the garage - removal of the fertile layer

Zero level mark

As a result, you turn out to be hit some depth. It will fall asleep crushed stone and sand, but to understand whether its depth or excessive is sufficient, it is necessary to determine the "zero" level of gender. Conveniently, if the floor is lying with the door threshold. They often make it just below the threshold, but then it will have to somehow make a removal of water, and it will definitely be if not in the spring, in the fall, in winter, with the monstering snow, - for sure.

Mark on the perimeter of the walls zero floor level. It is most convenient to do this with the builder of planes (electronic or level or level). Include the instrument to display the horizontal plane, exhibit at the desired level and draw on the beam.

With laser level work easier

If there is no laser level, use water. It is not so convenient with him: you have to transfer the mark many times on all four walls. These marks are connected direct, instead of the ruler, you can use a bubble level, at the same time you can control whether all the marks set.

Water Level will have to transfer marks to all walls

Calculation of the thickness of the PGS layers

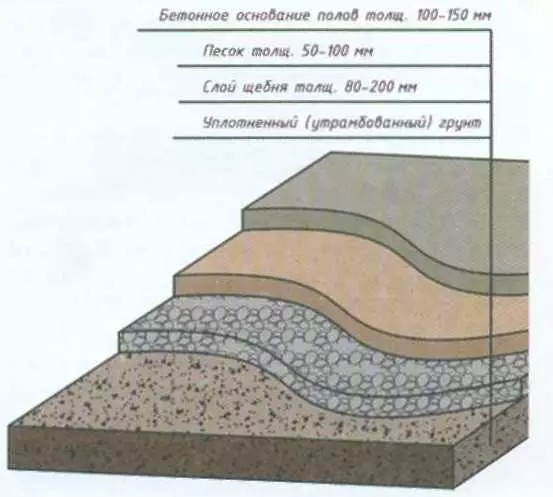

As a result of these works, we have a pit and zero floor mark. Now you can calculate what thickness layers are necessary to exit the desired height. It is necessary to proceed from such sizes:

- The optimal thickness of the concrete floor in the garage (if there is a passenger car or easier transport) - 10 cm;

- The thickness of the crushed stone layer is at least 10 cm;

- sand is at least 5 cm;

It turns out that the pit should not be smaller than 25 cm deep. And this is without taking into account the floor covering. If you are a concrete floor just to handle impregnation or paint, then no additional centimeters are required, for any other coating, add the required thickness.

Concrete floor structure in the garage

Having received a specific figure, you can plan the amount of sand and rubble. If the layers are very large, it is possible to fall asleep to the bottom and the ground (but not a fertile layer). If the depths of the pit is not enough, we take out a certain amount of breed.

On the walls of the garage, you can apply marks for which you can control the thickness of the layers. With a small garage width - 2 meters or so - these marks are enough. If the garage is wider, it is necessary to set several more stakes in the middle and they also apply marking. Affective thing, all marks must lie in the same plane. It is convenient to do this again with a level. Another way is to take a flat bar or board, attach to the applied marks. Top on the bar / board put the level. If everything is set correctly, the bubble will be in the middle.

Article on the topic: Where to throw out the construction trash?

If you plan to make a hole in the garage, it's time to dig under it a pit. If the pit is with the walls of the brick, you can immediately pour the concrete floor in it. While you will be drawn under the concrete in the garage, it will type the required safety margin and it will be possible to lay the walls. They can be expelled after frowning on the floor cushion cushions and sand.

Materials for submail

For a normal concrete floor in the garage, it is better not to take gravel, but crushed stone. Gravel, with its rounded edges, you never comply to the necessary degree. And if the base under concrete is unstable, even a thick reinforced plate burst. Therefore, bring crushed stone, medium and small fraction. Middle 60-70%, the rest is shallow.

Pillow consists of rammed rubble and sand

There is no special demand for the sand for the pillow of special requirements. It is important that it be without clay inclusions, but it is possible to sift it before stacking.

Make a pillow under concrete floor

First of all, it is necessary to align the bottom of the pit. We remove the irregularities, fall asleep the depressions, we derive the level into the horizon. Do not think that the concrete floor in the garage can be done with violations. You can do, but then the stove cracks, you have to redo.

Now we take the vibroplatform (you can rent) or manual tamping and compact soil. In the course of the case, once again aligning the plane. When the soil is sealed, you can pour rubble. They fall asleep not the entire volume immediately - 10 cm do not normally catch up. The maximum layer is 5 cm, but better - 3-4. We fall asleep the necessary part, distribute, resurrect (robbles) to achieve approximately one thickness. Take a tuck or vibrating plastic and trambam.

Better to rub the vibroplitoy

This rubble tumbler with a concrete floor in the garage is very important - a certain amount of rubble is driven into the ground. As a result, it becomes even more dense, the carrying capacity increases, the possibility of drawdown is excluded. Tamping is considered sufficient if it comes to the surface, you do not leave tracks. In the same way, all servings of rubble are trambed, bringing to the required thickness.

On the rammed crushed stone pour sand. It is also divided into pieces of 2-3 cm. Feature of the sand tree: it should be moistened, still say - shed. Wet sand trambed, again focusing on the layers.

Now you can take care of the pit walls, if it is. They are displayed in a level with a clean floor or even a little higher - so that you can wash the car right in the garage, without fear that water will fall into it.

Dampfer clearance

The concrete floor of the soil is often called "floating". This is because it is made incoherent with the walls of the structure. In this case, the walls and the floor can dry out or rising independently from each other, while maintaining integrity.

In order for the floor in the garage from the concrete, it was connected with the walls, along the perimeter put the damper tape (sold in construction stores) or cut into stripes thin sheets of foam (thickness 10 mm). The width of the bands - 12-15 cm - they should perform a little over the finish finish of the floor. The excess height of the damper is then cut into a floss with a floor.

Dampfer tape.

Waterproofing floor of concrete in the garage

The moisture concrete itself is not afraid, the increased humidity is harmful to the body of the machine, as well as for things and equipment that a lot in the garage is gaining. The choice of materials for waterproofing depends on how close the groundwater is located and how highly they can rise in the season.

If the groundwater is high, no special measures for waterproofing can be done, but to be used on the sand dense polyethylene film (density of 250 microns, you can reinforced, you can not). In this case, the film is more needed so that the moisture from the concrete does not go into the sand, which is impossible to allow. With the lack of moisture, the concrete does not gain the required strength and will crumble.

Article on the topic: Auditing hatch under the tile - Hidden access to communications

Waterproofing film Pullion

With a high level of groundwater, it is better to take waterproofing more dense and reliable - hydroizol or its analogues. In any case, the film panels spread overlap - they overlap each other by 10-15 cm. To minimize the possibility of water penetration, the joints are sampled with two-way skotch, you can double (at the beginning of the joint and at the end).

Waterproofing starts onto the walls, above the damper tape. There it is temporarily fixed. After the fill of the concrete and its setting it can be trimmed.

Reinforcement

Since the loads are assumed to be serious, concrete floor in the garage reinforced. Under the passenger cars, you can use the finished mesh from the wire of 7-8 mm in diameter, the cell size is 15 cm. To obtain a single reinforcing system, mesh pieces are placed at each other by one cell. Two grids are binding to one with another plastic clamps or a special knitting wire.

The waterproofing of the floor in the garage is made by hydroograph, the reinforcing mesh is installed on bricks

Another point - the grid must be in the thickness of the concrete, in about the middle. Just put it on the film will be incorrect - the metal is not corrosion inside the concrete only if it is at a depth of at least 3 cm. In order for the concrete floor in the garage for a long time and did not crack, the grid is lifted over the waterproofing by 3-6 cm. There are special support for this, but more often use halves of bricks. They just have a thickness of 6 cm. Lining them under the reinforcing grid so that it is not very troubled.

Installation of Mayakov

So that the floor in the garage was even, it must be aligned. It is more convenient to do this with a special long strip, which is called "rule" (emphasis on the letter "and" from the word edit). This bar is based on the smooth planks set by the desired level. They are called lighthouses.

Any smooth and long items can be used as lighthouses. It can be pipes, bars, special lighthouses that are sold in building stores. They must be set in one level with a concrete slab applied on the walls.

They put lighthouses from the far wall, towards the one in which the doors are arranged (most often it turns out that along the long wall). Installation step - 25-30 cm already than the length of the rule. If a rule is 150 cm long, the distance between the beacons should be 120-125 cm. From the walls, about 30 cm retreats, they put the first lighthouse, then others with a predetermined distance.

So poured concrete floor in the garage on beacons

It is usually installed on the islands of the densely mixed solution. Lay out the slide a little higher than necessary, the lighthouse is pressed into it so that it is at the right level.

When installing lighthouses, it is possible to make a light slope of concrete floor towards the doors (0.5-1 cm per meter). In this case, the water will be self-shot from the floor to the street. Just note that concrete in this case requires more - it is necessary to decide the far from the entrance of the edge of the floor, but this is compensated by ease of operation.

For the next day, after the fill, the beacons are removed, the emptiness is filled with a solution and align in one level with a previously filled floor.

Concrete Filling in Garage

Brand concrete for the floor in the garage - M250. Its characteristics are more than enough for strength and frost resistance. Due to the fact that the stove thickness is large, even in a small size, the garage requires a large volume of solution. Let's estimate: on a small garage with dimensions 4 * 6 m with a thickness of concrete floor, it will take 4 m * 6 m * 0.1 m = 2.4 cubic meters. With the fact that you need a bias, it will be all 3 cubes. If you do it with your hands in one day, you need to use two concrete mixers - one will not cope. For work it will take a decent team.

Article on the topic: Plastic roof drainage: Montage with your own hands with ties, gutters, pipes

To knead the concrete in the concrete mixer you need a big team

Each concrete mixer should stand one person. This is provided that all components are immediately and they will also download them to the pear. If the components need to be taken - these are two more people. Plus, two should carry the concrete to the place of its laying and one - Rush. There is a considerable brigade. The composition will have to work all day. Even if the helpers are free, feed them to feed them. It is unlikely that this alignment will help save a significant amount of money compared with the order of finished concrete from the factory. Unless you work in one hands, pouring the floor in parts. This is also possible, but can threaten the cracks in the fields of the sections of the floor sections, filled in one day. It is possible to reduce the chance of the appearance of such cracks if you remove the cement milk with a metal brush, which is formed on the surface.

If you decide to order concrete in a mixer, it is worth installing a receiving tray, which will send the stream of concrete to the center of the garage. From the center it is already easy to distribute in all angles, and then stretch the rule. To facilitate the recreation of concrete and increase its brand, immediately after the preliminary distribution of concrete, processed by a submersible vibrator for concrete. At the same time, air bubbles come out immediately, the concrete becomes more fluid and fills all the cavities. Lighthouses will be needed only for orientation, and maybe partial alignment.

Curing

After filling the concrete, if the street is not very hot, you can simply close the garage doors. If there is a window, it must be drilled so that the sun's rays do not get on the concrete. If the street is too dry and hot, concrete is covered with polyethylene film or wet burlap.During the week, the slab must be daily water. It is more convenient to do this in burlap - it is possible not particularly tormented by relatively small jets to water the burlap, and she will give moisture concrete. If the concrete floor in the garage covers the film, it is removed before irrigating, then stretch again. When watering in this case, it is necessary to ensure that the drops are small - you need a nozzle with a lot of holes. In any case, the degree of irrigation - to a evenly wet state (it is determined on the dark gray surface of the surface), but without large puddles.

Insulated concrete floor in the garage

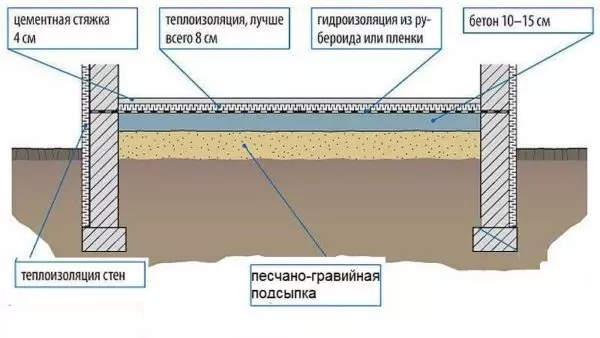

There are two options - insulate the already flooded slabs, the bay on top of the screed (the structure in the figure below) or make insulation immediately, putting it under the main plate.

Insulated floor in the garage

When choosing a second variant, the insulation is stacked on top of the waterproofing layer, the reinforcing grid is set on it. All the rest of the filling process in the garage is similar, only it is necessary to take into account the thickness of the insulation when calculating the depth of the pit.

As a heater for a given case, it is recommended to use extruded polystyrene foam (EPPS) with a density of at least 35 kg / m3. It has very good characteristics, can withstand heavy loads, does not absorb and does not let water or steam. So this is also additional vapor-waterproofing.

So that there is confidence that under the wheels, the insulation is not sold, it makes sense on top of it to lay a layer of geotextile. This is a nonwoven membrane that is used in the device of highways. Its function is the distribution of the load, just what we need.

The minimum EPPS thickness is at least 5 cm, better - 8 cm. Stop it better in two layers, when laying shifting the seams - to isolate the floor from the soil as much as possible.