Drilling wells is most often required when the well device is on the water, but also periodically, such works need: install metal poles for the fence (gazebo, pergola), create a field for collecting heat from the ground when the heat pump device, earth-air, with a column foundation device And many other construction work. Easy and significantly speeds up the processes of a small-sized rig. Having some welding skill, you can make it with your own hands.

Homemade drilling rig

Types of homemade drilling rigs

For independent drilling of wells (on water and not only) it takes at least a small drilling rig. The depth of wells is rarely less than 20 meters and without applying the simplest mechanisms to do is very difficult. If we talk about the drilling techniques and types of butt installations, you can make the following drillings:

- Shock-cable setting. The principle of operation of this type of equipment is based on the strength of gravity. At some height, a heavy drilling rig in the sharpened edges is a glass or an illegum. His "drop" a few dozen times. Each time, the shell cuts over some part of the soil, and the breed is stuck inside the hollow projectile (for bulk soils they are supplied with valves). The glass is removed from the well, the soil is removed. Next, the process continues until the well reaches the required depth. For self-execution, such devices are the simplest. In the most budget version, this is a kind of bed that allows you to fix the block over the well. Through the block, the long cable with a tied iron is thrown. For the cable, you can pull "manually", and you can install a motor reducer with a drum.

One of the shock-drill plants

- Auger rig. The recess in the ground occurs with the auger - a rod with a welded screw blades. Schneck can be manually dried well in a couple of meters - under the pile foundation, for example. To pass dense layers of clay or dense sands, a solid effort is required. Therefore, the engine is required with a large torque, and they work from 380 V. and then the screws are practically useless on stony soils. And anyway, it's just a small stone type of rubble or rock breeds - the screw will not pass.

Auger rig

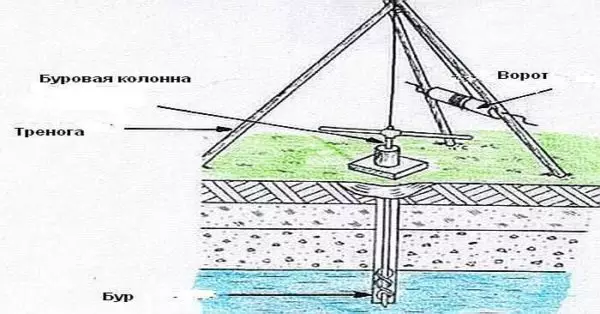

- Rotary drilling. The principle of rotation is also used, but a drill solution (water) is supplied inside the bera. This is an effective way - water takes place on the surface of the sludge (fragmented breed), and the bee is very rarely removed on the surface. Its only on top are constantly increasing, installing additional rods. There are rotary installations of "dry" drilling - without solutions, but they require great effort, the drilling rate is much lower. Therefore, such installations are made and used rarely.

Rotary rig

Selecting the type of drilling rig for making it with your own hands depends on the geology of the area, where the depth of the aquifer of aquifer also affects. The most universal method is shock-rope. Different soils are well undergoing using rotary equipment using water (this method is also called a hoist). For different types of soils, different shapes are used, and the chopped soil is washed into the surface with water.

The most "capricious" junction of the screw boring, but he copes well with viscous soils - clays, loam, but with boulders and stony soil he gets stuck.

Water purification methods from well or well are described here.

Types of homemade cable-shock drill plants

In the manufacture of the drilling rig under the cable-shock drilling, there are two important elements: a bed and a glass (cartridge, ulute). For the simplest option, you can make a box of three-four pipes, which are connected above the place where drilling will pass. There is a fastener block, a flexible steel cable is thrown through it. At the end of the cable tied a drill projectile. That's the whole design. This "installation" of muscle strength is activated - for the cable is pulled, then sharply lowered. Shell gradually deepen.

The most simple designs

To reduce physical exertion, a winch is installed for even greater automation - a motor with a gearbox rotating the shaft of the winch. At the same time, it is important to come up with a system that will allow the release of the winch shaft and reset the ulute.

Rama-Trenoga is not always convenient - it requires a large area. Moreover, for the stability of "legs" should be at an equal distance from the center. Also the jumpers between all the supports will not. In this case, the drilling rig will stand reliably. There is another option of the frame - in the form of the letter "H" with telescopic rods (in the photo below).

Made with your own hands mini rig

Vertical stand also telescopic. It allows you to change the height with which the projectile is reset. The rest of the equipment is the same.

Bed for a small drilling rig side view

How the drilling drilling drilling drilling drilling rig made by their own hands from the girlfriend, look in the video. This design is accurately repeated.

For details on how to break through and equip the water well is described here.

How to make installation for rotary drilling

The drilling hydraulic installation must have a bar, which allows you to move up / down the motor to which through the swivel is connected by the Boer. Also through the swivel inside the column amenable to water.

Principles of constructing drill

In the manufacture of the drilling rig with their own hands, this procedure is recommended:

- First there must be swivel and rods. If you are not a qualified turner or you have no such thing on accept, then these details are better to buy. With their manufacture, high accuracy is required, which can be achieved at high qualifications. Moreover, the carving on the swivel and the rods should be the same, or the adapter will be required. The carving on the rods is better - a trapezium, since then a conical few of the Tokarei can do.

- Buy motor gear. If the power is from 220 V, then the characteristics of it are: the power of 2.2 kW, revolutions - 60-70 per minute (the best: 3MP 31.5 or 3MM 40 or 3MP 50). You can only deliver more powerful in the condition of the presence of power in 380 V, and more powerful are rarely needed.

- Buy the winch can be manual or electrical. Load capacity is preferably at least 1 ton (if possible, better - more).

- When all these components are available on hand, you can cook the frame and make a boring. After all, all this equipment is attached to it, and the types of fastening can be different, impossible to guess.

Homemade drilling rig

The mini-rig frame consists of three parts:

- horizontal platform;

- vertical frame;

- Mobile frame (carriage) on which the motor is fixed.

The base is cooked from a thick-walled pipe - the wall thickness is 4 mm, at least 3.5 mm. Better - from a profiled cross section of 40 * 40 mm, 50 * 50 mm or so, but the round is also suitable. In the manufacture of a small rig frame, the accuracy of unimportant. It is important to comply with geometry: vertical and horizontal, the same tilt angles, if necessary. And the dimensions are "customized" in fact. First, the lower frame is boiled, measured. Under the existing dimensions, a vertical frame is made, and by its size - the carriage.

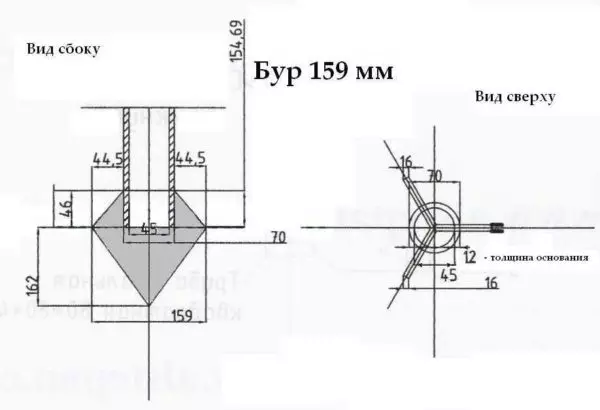

Simple forest forts can be made independently - they are boiled from ordinary steel (drawing in the photo below). If you take high-alloy steel, it is difficult to welcome to the rods. For complex and stony soils, it is better to buy a car in a specialized campaign - they have a complicated form, there are many different species.

Bura drawing by 159 mm

To work it easier, two remote controls are connected with the possibility of reverse stroke. One put on the engine, the second on the winch. Here, in fact, all.

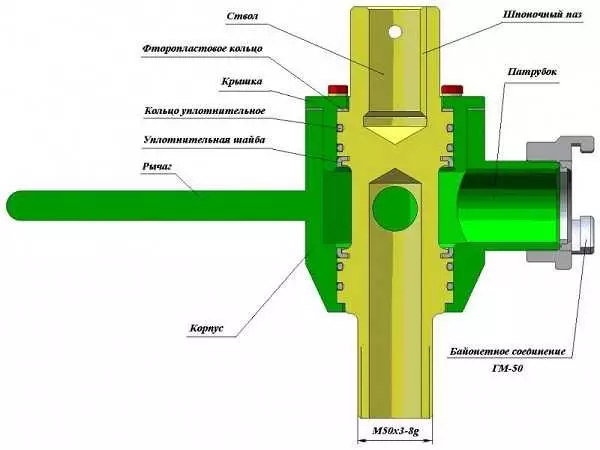

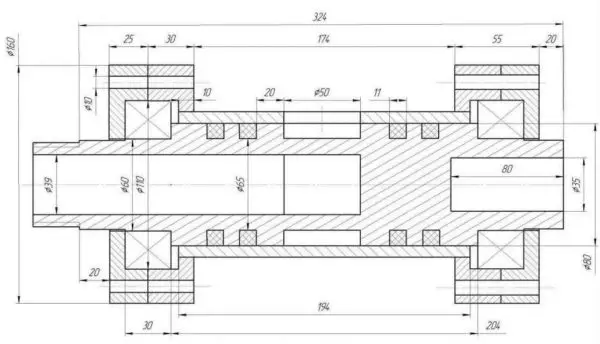

In the design of the drilling rig or screw drilling, the main thing is the swivel, but it is impossible to make it without experience. For those who want to make it on their own, lay out the photo and its drawing.

Vertiluga device for butt installation

Helicing drawing for small rig

How to spend water from the well to the house read here.

Simplest installation for screw drilling

If the aquifer is shallow layers, the soils are soft, you can do the mechanical drilling rig with a screw. This is the same tripod or any other frame with a block through which the cable is shifted. Only instead of a venture or drill glass to the cable tied auger. In its upper part there is a crossbar, with which it turns it.

Hand Rig with Schneck

To facilitate the process, the presence of a winch or at least a gate (by the type of well). But you can make a rotary drill, similar to the above described. Only the structure of the swivel changes - it is needed without removal under the flow of water. The work of one of the drill plants collected by the master man with his own hands, from the primary materials - on the next video. You can consider the features of the design.

And the last moment is a video about how to make a screw for the rig with their own hands.

Article on the topic: Wallpapers for the attic: Proper design