The modern market for finishing materials offers many practical solutions for finishing the bathrooms. More recently, those who were going to make repairs in the toilet were only two options - painting walls or facing with tiles. Now you can choose immediately from several available options, each of which has its advantages and disadvantages.

In today's article, we would like to tell you about one of the easiest and most convenient ways of finishing the walls and the ceiling in the bathroom - plastic panels. You will learn about the features of this finishing material, about the basic principles of working with it, as well as how to choose the right plastic panels in the toilet.

pros

To begin with, consider the positive aspects of the use of plastic panels as a finishing material for the bathroom. The list of advantages of these products is quite impressive:

- Low price. This method of finishing surfaces is one of the most low-cost. It will be cheaper except that painting with water-emulsion.

- Easy installation. Plastic panels do not require special skills in the sphere of repair. Even one who took up repair for the first time can cope with their installation.

- Speed installation. Installation of one panel of PVC takes a few minutes. Since the bathrooms usually have a very small area, all work will take you extremely little time.

- No need to prepare surfaces. Under the plastic panels do not need to align or stucked the walls.

- Neutility in care. PVC is a waterproof material that perfectly transfers wet cleaning and contact with various detergents. Therefore, to maintain the purity of the walls in the toilet will not be difficult.

- Wear resistance. Despite the fact that plastic is fragile material, if not to expose it to a strong mechanical exposure, the panel of PVC will serve you long enough.

Minuses

However, plastic panels have not only positive sides. Negative qualities of this finishing material are not so much, but still they are present, so it is impossible to silence about them. So, the laptops of PVC panels are:

- Instability to heating and fire. Plastic panels are deformed under the action of high temperatures, so it should not be close to them heaters and toweling devices. In addition, plastic is not a refractory material: it can catch fire from contact with fire. Therefore, with smoking in the toilet, you need to be careful.

- Large dimensions. At first glance, it seems that plastic panels are absolutely flat, but in fact they can be thick up to 2 cm. In addition, a few more centimeters of space often "eaten" if the walls are indoors are uneven. For large bathrooms, this is not critical, but in small-sized toilets it can become a real problem, as it will not allow to use the tiny area to the maximum.

Article on the topic: Cardboard fireplace from the boxes do it yourself

Types of panels

Plastic panels designed to finish the walls and the ceiling in the bathroom, there are several varieties.

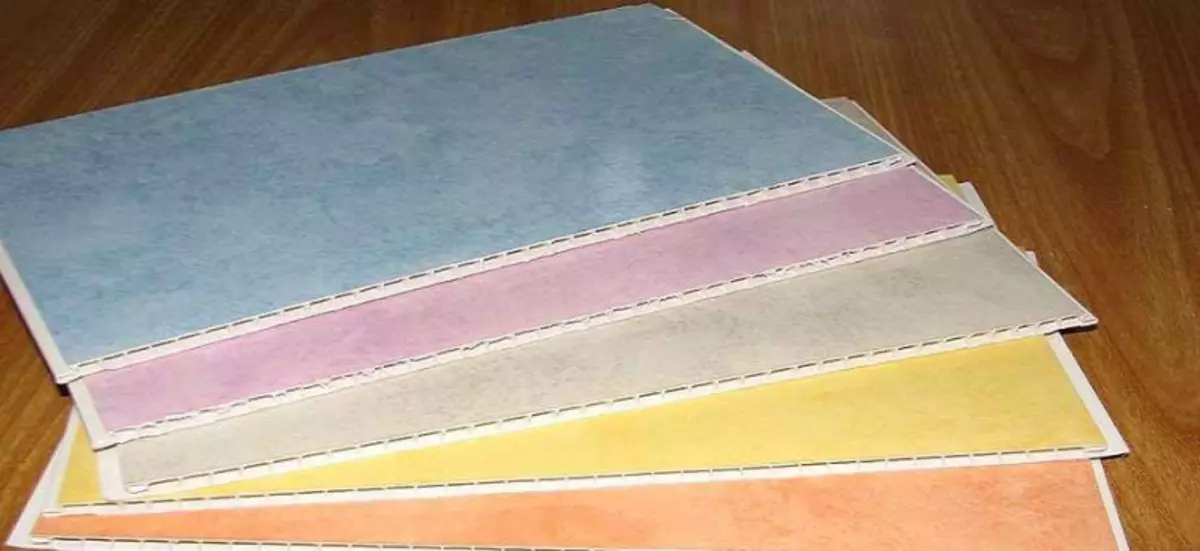

Leafy

The most popular view is the leaf panels, which are rectangles from one to one and a half meters long. The thickness of such panels is 0.3-0.6 cm. They can be monophonic, with an ornament or imitation of natural structures - wood or stone. Working with sheet panels is most convenient due to their large dimensions.

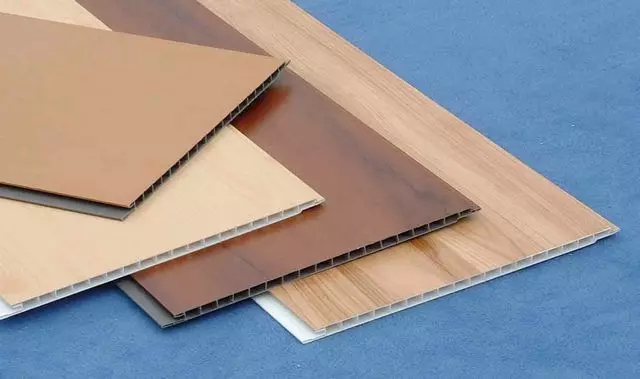

Rachet

Rush panels for finishing the bathrooms are used much less frequently. More often they are used for exterior work or large areas of premises. This type of plastic panels is similar to long narrow strips. The length of such panels is from 4.4 to 3.7 meters, and the width is from 12 to 30 cm. Hard panels, imitating wooden timber, especially spectacularly look.

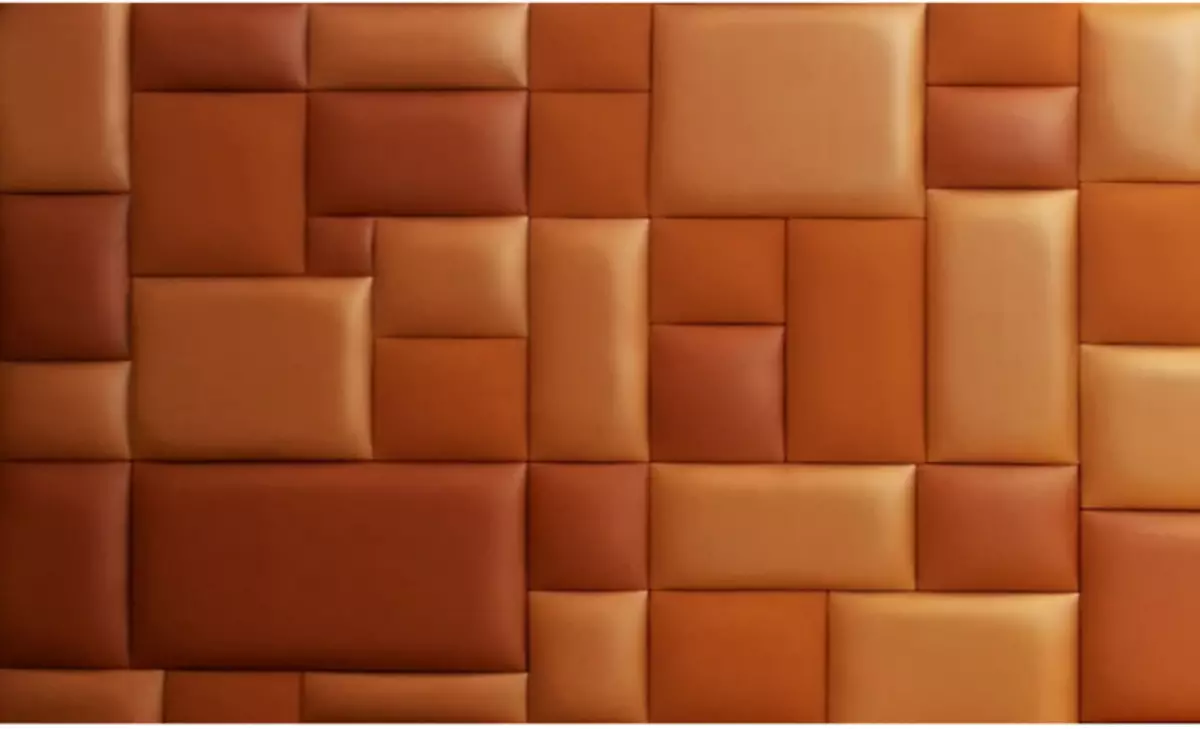

Set of tile

The least common variety of plastic panels is a typeset tile. They are squares of different sizes, which allows you to lay different patterns on the walls and ceilings, like from mosaic. The connection of the elements occurs through the pubs in the panels, and is fastened with all with special glue or cleathmen.

Tips for choosing

- If you want to purchase a product with maximum strength, choose plastic panels with a thickness of at least 0.8 cm. In addition, pay attention to the number of "edges" on the inside - it is they give extra rigidity.

- The quality of plastic panels can be determined by its appearance. Carefully look at the front of the product: the paint should be applied evenly, and the drawing, if it is, is printed well.

- As in the case of wallpaper, the color of the same wall panels and different batches can vary by several shades. Therefore, buy products only from one party.

The high cost of wall panels does not always talk about as high quality, so the price should not be a determining factor when choosing. However, the material that is much cheaper than its counterparts from other manufacturers is usually made unfair.

Preparation and repair stages

Before starting the toilet finishing with plastic panels, some prerequisites should be conducted. To this stage of repair, you already need to install the toilet, align the floor, lay out it with ceramic tiles or clamping linoleum.

Article on the topic: Is it possible to glue phlizelin wallpaper on the ceiling tile?

Specialists advise prepare the plastic panels to install and further exploitation, processing them with an antiseptic agent. This will protect the material from heat and moisture, so the appearance of fungus and mold can not be afraid.

Next, the installation of plastic panels in the toilet will be held in several stages.

- Stage 1. Installing lateral racks that will serve as a base for the frame.

- Stage 2. Diseases design with rails and crossings.

- Stage 3. Fastening plastic accessories.

- Stage 4. Cutting and installing plastic panels.

Basic principles and installation

Consider each of the above-mentioned stages of work in more detail.

- Each of the corners of the room should be put on one rack. At the same time, they should not be in contact with the floor and the ceiling, so there are any material between the racks and surfaces. After the design is fixed by screws, the temporary support will need to be removed. It is necessary to put the side racks on a plunder so that they are strictly parallel. Between the fasteners, we observe step 0.3-0.4 meters (we use screws as fasteners).

- The side of the side struts is performed by wooden bars around the perimeter of the construction from above and below. Fasteners should be screwed at an angle of 45 degrees - so we can securely fix two rails at once. Next, the rails need to be fixed on the walls using self-tapping screws. This is the main framework, which, if necessary, can be supplemented with side racks or transverse rails. The step between the frame elements should be about 0.5 meters.

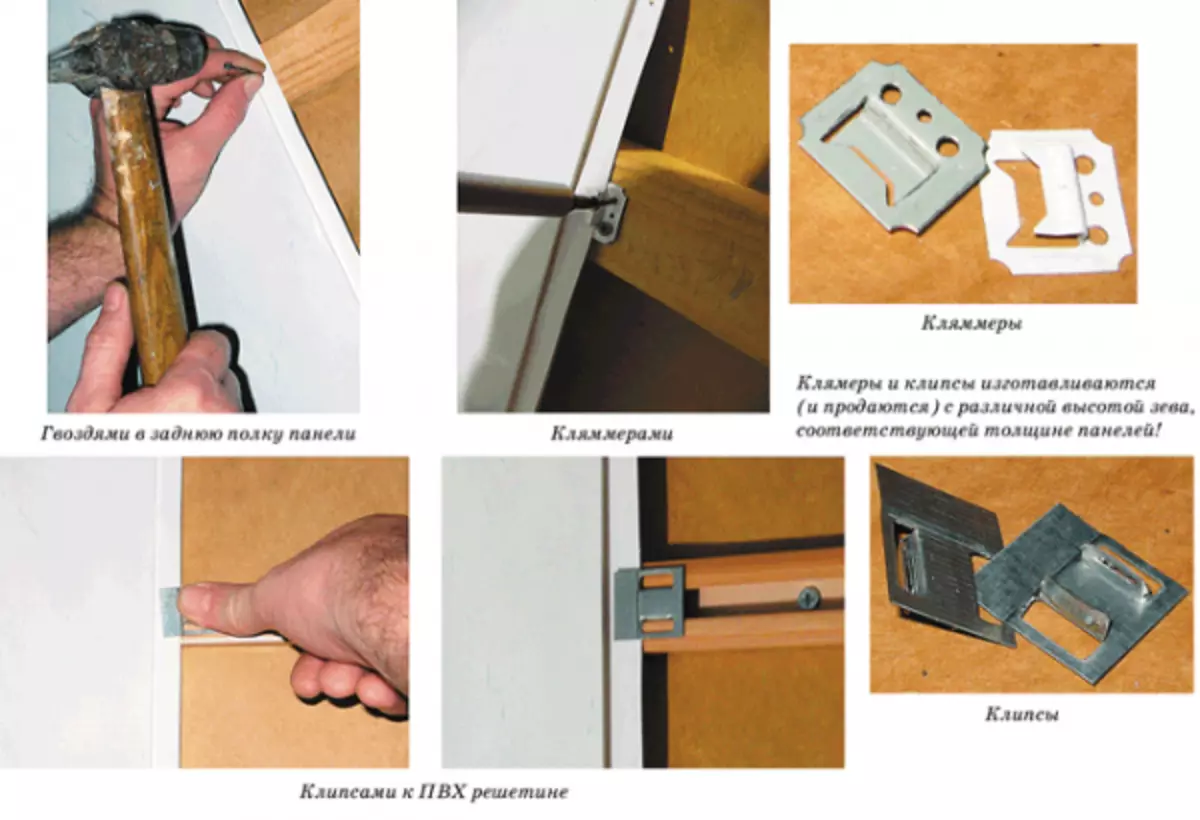

- Plastic accessories nail to the frame using nails and a hammer. Fittings need to trim at an angle of 45 degrees - so it will fit the tight. Since PVC panels are quite plastic, fittings are installed, including in the corners. If there is a gap between the rail and the wall, lay it with cutting plastic, then score a nail. Nails for mounting should be selected with large flat hats. In order not to damage the plastic elements, scoring nails, we do the last strikes without a hat, but by a protective nozzle (for example, you can use a nail).

- The final stage, with the proper installation of the frame and fittings, takes quite a bit of time. Plastic panels we cut with a hacksaw. At the same time, the size of each sheet should be on a centimeter-one and a half less than the place prepared for it, since the missing length compensates for plastic fittings. Sliced leaf insert into the grooves and secure to the raids. Insert the next sheet into the previous one, then also nail it to cross.

Article on the topic: crafts from the cones: What can be made of spruce and pine cones for home with children (100 photos)

The last panel mounted somewhat differently. Sut it along the entire length, then we turn into the angle until the stop and drive in the lock of the previous panel using a thin screwdriver. To lock this panel with nails will not be able, so it is necessary to provide in advance in advance the most inaccessible place in the room.

Advice

- Before proceeding with the purchase of materials and finishing the toilet, sketch a simple design project of the future room. Think not only about the color scheme and the placement of interior elements: it is equally important to provide for the location of windows, niches in the walls, plumbing box and ventilation.

- In advance, take care that you have all the necessary materials and tools at hand. In addition to the plastic panels themselves, you will need: metal profile, wooden bars, nails, screws and screws, hammer, silicone glue, construction level or plumb, hacksaw or cutter, perforator with a drill set.

Toilet planning tips with plastic panels read in another article.