Vitaly, Voronezh asks the question: Hello! I consider myself an experienced homemade master, but never had to face using the construction, repair or manufacture of profile structures. I heard that it has a fairly wide range of applications. I would like to know the opinion of a specialist about whether this is true, and for what reason the metal elements have become so common in private and industrial construction. If the quality of this product is so high, then I would like to know how the aluminum profile is fastened, since I also intends to apply it when performing a kitchen headset and the installation of the ventilated facade of your country house. In what sequence to fix the facade pie, if it is assumed to use the metal component in the process? The expert replies:

Ventilated facade of the building.

The mounting of the aluminum profile is distributed, it is due to the fact that the products are not only economical, but also universal self-supporting structures. The process of attaching aluminum profiles is often produced during the arrangement of the facade systems, these products act as an element of the carrier component.

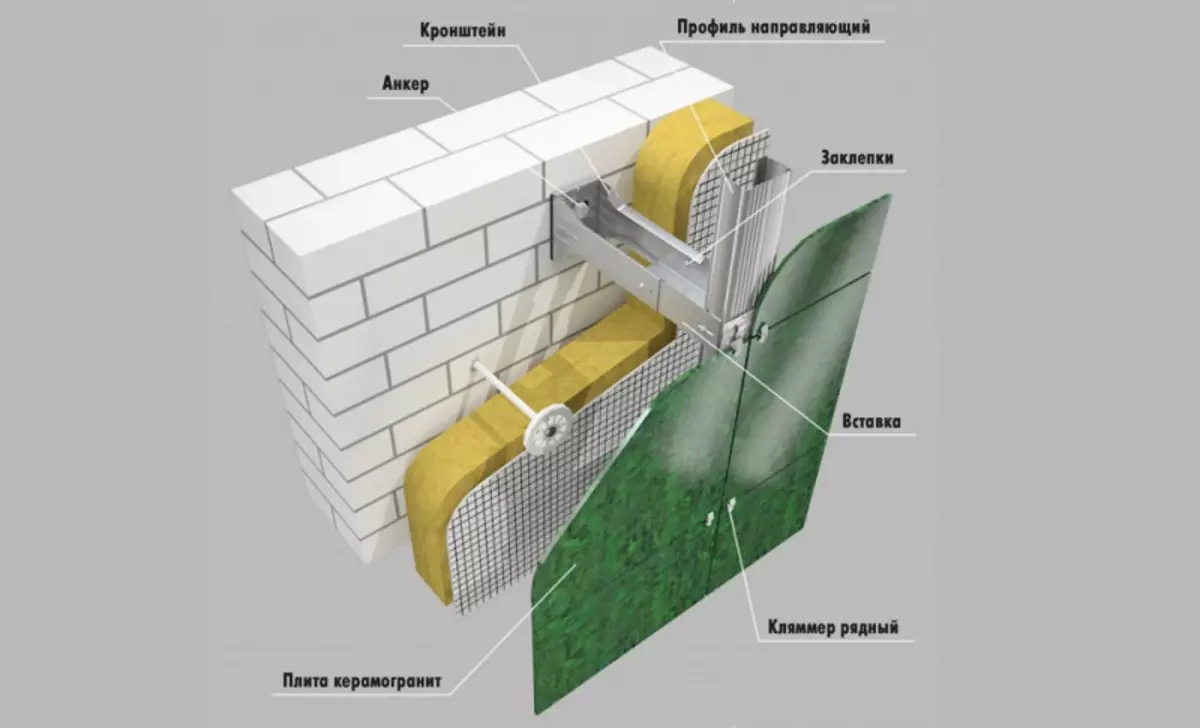

The fixation is made by means of facade anchors to which the metal element is installed. Until the start of installation on the wall, the heat insulator should be mounted. Its fixation is made by umbrella dowels. After that, the facade insulation protects the membrane that prevents blowing and wetting. The membrane must be attached to the braziness between metal elements. The installation process should be done in such a way that there is an air layer between the insulation layer and finishing of the facade.

The facade anchor is used to fasten the profile to the outer wall of the building.

Aluminum elements can be used inside the house, for example, when making doors for a kitchen headset. The role of filler in this case protrudes MDF. From the stove it is recommended to cut a rectangle with certain dimensions. To one of the ends of the workpiece from the MDF, a C-shaped bar should be performed. Only after that the size of the element is permissible to correctly correct the hacksaw so that its length is equivalent to the length of the segment of the segment. The workpiece must be put on the end, and then strengthen with a stapler and nails. In order for the facade, enclosed in an aluminum component, was deprived of external defects, it is necessary to install a decorative bar, which will close the fastener hats.

Article on the topic: How to independently make a podium in the apartment

In order to make the corners of the facade of nonostile, they will have a decorative angle to be put on, which will be connected to each other. After that, by the same technology, it is necessary to adjust the element for the other side of the MDF workpiece. It is necessary to install the material in the corner, and then in the same way to strengthen and produce decor. Once the facade is ready, it is necessary to equip the recesses intended for canopies using a milling saw.

Facades based on the described component will have characteristics of strength and aesthetics.

Aluminum C-shaped strips can have any color. In addition to the simple installation, the profile has a low price, it saves on the production of structures from the material.