When choosing pipes, it is necessary to take into account the large number of their features. For example, in addition to accounting for physicochemical properties, it is necessary to consider which length and diameter will be. It turns out that the hydrodynamics of the entire heating system directly depends on the diameter. Most often used and used for private houses are pipes with a diameter of about 16-40 mm.

The diagram of the device of the polypropylene tube.

Pipes of this size are able to withstand the pressure in the heating system, in addition, it is convenient to use them in operation, they will not create problems in the installation process. Using them, you can provide a lifting of a hidden pipeline.

Which diameter of polypropylene pipes is used for heating

To properly select the size, the inner diameter of the pipes is calculated according to the following formula:

d = √ (4-u-1000 / πl),

where u is a value that is equal to the total water consumption in the house that will fall on this water supply,

π - 3,14.

L is the flow rate of water, for the pipes of large diameter it is considered to be 1.5-2 m / s, for a small - 0.7-1.2 m / s.

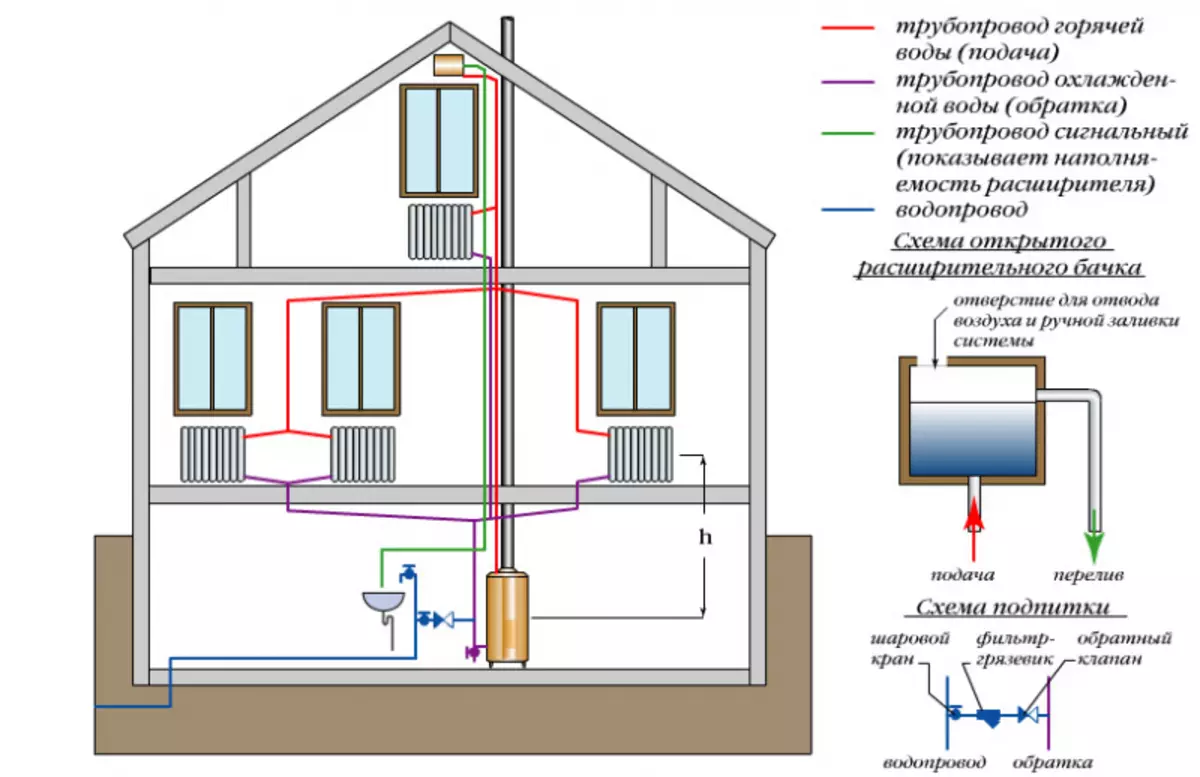

Scheme of the home heating system.

Polypropylene materials for heating are used in diameter of about 20-32 mm. To mount the warm floor, plastic with a diameter of 16 mm are most often used. It is also important at the beginning of work to estimate all its complexity and choose the necessary material. Given the various factors in the heating system, you need to correctly calculate the pipe cross section. It is important here a lot: the temperature of the carrier, the flow rate, the length of the pipeline, the diameter of the pipe and the water pressure is hot.

It is believed that only the correct size of the desired diameter of polypropylene pipes for heating will help make the entire system reliable and efficient. In cases of incorrectly selected size, some deficiencies in the system are possible. For example, if the diameter is larger, the pressure in the heating system will become below the desired, which will lead to violations in the circulation of water for all apartments in the Big House. And only the repair work will be able to establish the operation of the system, which suggests the replacement of pipes on the proper size pipes.

How to choose the right diameter pipes

In cases where heating is carried out in a private house or cottage, the pipes should be selected, taking into account the fact that the diameter will not change only when there is a direct connection to the central heating system. In the case of an autonomous pipe system, you can use any size (different diameter and length), depending on the preferences of the host itself.

Article on the topic: How is the electric heated towel rail?

Choosing the necessary workpieces, you need to take into account all the features, especially if we are talking about the natural heating system, where the ratio of the cross section to the power of the pump will not be a primary sign. This fact refer to the advantages of this heating system.

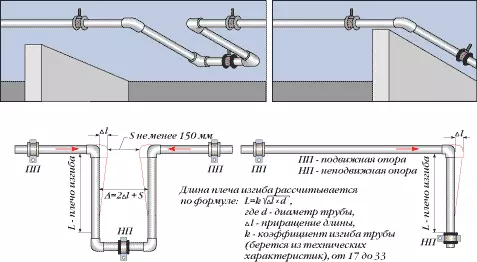

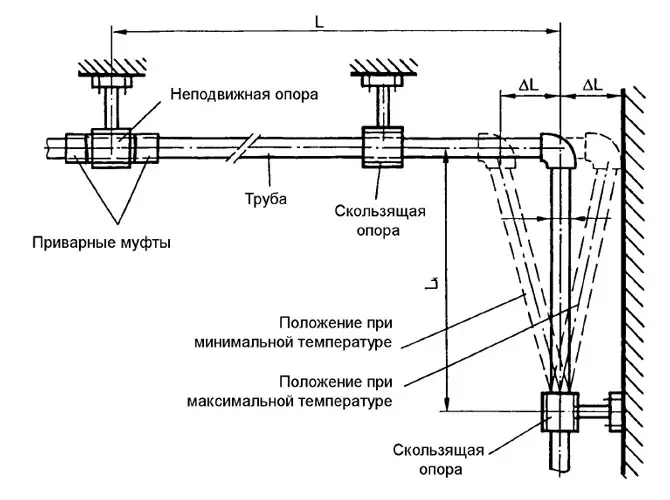

Pipe mounting scheme.

The disadvantage of such a system is a small radius of action and the greater the cost of the elements of the large size used in this case.

To ensure the efficiency of the system, it is necessary to maintain a certain level of pressure, allowing moving inside the water to overcome all obstacles in its path. Resistance (obstacles) can be in the form of friction of water about walls, removal or crane and heating instrument. The most interesting thing is that precisely from the length and diameter of the pipeline pipes depends on the resistance and the speed with which water will flow. With a high speed of water, a small cross section and a long pipeline, the resistance level on the water path rises.

What pipes are suitable for the heating system

Any heating system involves drafting a project scheme. After that, it is necessary to prepare in advance and choose all the necessary (materials and tools for installation work): pipes, reinforcement and necessary tools. And only after that, it is possible to start the installation of polypropylene pipes.

Elements are selected for a certain room, given all its features and type of heating. It is important at the preparation stage to determine their strength and understand what work will be. After all, the installation is not always easy to do with your own hands, sometimes you have to seek help to professionals.

For heating systems, the use of polypropylene, metal and metal-plastic materials is possible. All these materials have their advantages and disadvantages that need to be taken into account when selecting for their system. Polypropylene is considered the optimal material for the elements of the heating system. In turn, metal differ in an overestimated price, as well as complex in use, they are unstable to corrosion, which leads to a decrease in their service life. Metal-plastic materials are cheaper, easy to use, but their reliability and durability leaves much to be desired, so it is better not to consider this option for mounting the heating system.

Scheme of heating from polypropylene reinforced pipes.

From here we can conclude that the polypropylene is best used for the heating system, as it serves as a good option for mounting pipes for water. It is important to know and be able to separate different types of polypropylene pipes that are designed for hot or cold water. Use materials only for a specific type of work. For example, pipes for heating, where hot water will go, you should not use for pipelines with cold water, as the temperature regime will be different and various disorders and malfunctions are possible.

Article on the topic: Flooring is your own hands: Wooden painted cyclishing, such a video for the board, the tool is old

To mount a warm floor or the heating system, you can safely choose polypropylene elements that have a large number of positive characteristics, among which it is worth noting the following points:

- Reliability.

- Durability (operated for 100 years).

- Infertility corrosion.

- Lack of mineral precipitation.

- High resistance to the effects of chemical compounds.

- Easy mount.

- The ability to carry out repair work in cases of malfunction or breakage.

- Availability of price.

The only one, but the main disadvantage of this type of materials is melting and instability to high temperatures.

For the heating systems, the right choice is needed, which depends on the correctly selected diameter.

The diameter of the pipes should be not very small, but not large, so as not to affect the cost of the system and head of water in it.

Installation of the heating system using polypropylene pipes

Installation of the heating system involves the right choice of the work scheme. For example, the use of polypropylene pipes provides several options:

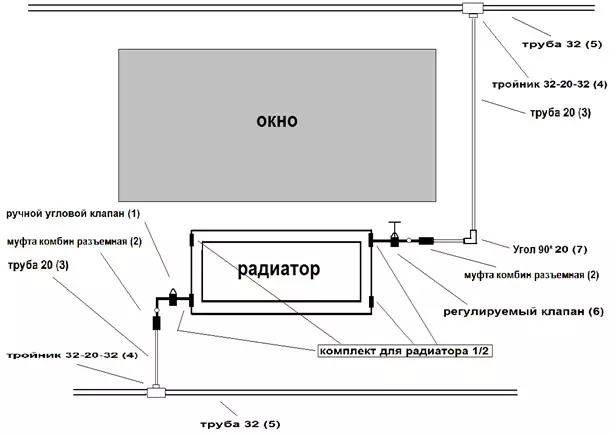

Mounting scheme of hot water pipes.

- Self-type water circulation in the system. In this case, there is no need to install a circulation pump, since the movement of water will be independent. This option is suitable for premises where frequent are the probabilities of problems with the operations of electricity operations, which will lead to the impossibility of using the pump.

- Lower spill system in heating. In this system, there is a radiation layout that assumes the presence of a pump used to increase water pressure, for which a smaller diameter is needed.

- It is possible to use single and two-pipe systems with connecting to the radiator using a side or lower type of connection.

Installation of the heating system from polypropylene pipes

Installation of polypropylene elements can be easily carried out both personally, and it is not necessary to trust this process of work to the masters. When installing, welding (soldering) is applied, in no case cannot be used threaded compounds for polypropylene pipes.

Before welding, the billets are cut into segments of the desired length using special scissors, so that the edges turned out to be smooth, without burrs, and all this turns out very quickly. The welding process is performed using a special apparatus intended for this purpose. For welding, it is necessary to insert the pipe into the nozzle of the correct diameter (the diameter must match the nozzle) and heat up to a temperature of 260 degrees. The heating time of the pipe depends on its diameter, for example, 20 mm pipe will be heated for 5 seconds, but a pipe with a diameter of 50 mm will be sinking 18 seconds.

Article on the topic: how to make a plasterboard arch - phased technology of installation and decoration

After the end of the pipe is heated, it must be connected with a heated fitting and hold out within 7 seconds to cool the parts and formed a very sealed and reliable connection as a result. It is important to know and take into account that in the process of work it is necessary to use only dry and clean elements, this is largely affected by the tightness and reliability of the entire compound and the heating system as a whole.

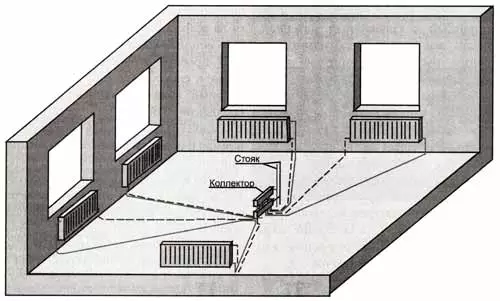

Scheme of collector pipe wiring.

If it is necessary to repair on the already created pipeline system, it is necessary to drain all the water before starting work. The use of reinforced elements from polypropylene implies preliminary stripping, involving the removal of foil from the pipe on a plot of 15 mm using a special acute knife. In cases where the aluminum layer is located inside, then the welding is carried out without this stripping.

In the process of soldering pipes, it is important to monitor the temperature regime, it is impossible to allow overheating, otherwise the formation of internal adhesions is possible.

When the whole work process is completed, the entire pipeline system must be checked and produce. In the case of easy air passage in the system, you can be sure that there is no smell. If there is some obstacle to air, it is necessary to remove it in the shortest possible time and do not postpone on then. Otherwise, this defects can then pour into a big problem. Yes, and again return to the work done, then hardly wants.

When all the work is fully completed and verified, water can be connected and check the system already with water. It is important to check all the joints, make sure that the water does not succeed anywhere and does not eat. All work should be made by pipes of one diameter so that the system is reliable. The main thing is not to forget about the aesthetic side of it.