Today, plastic windows are used among consumers with the greatest demand, but this does not mean that the wood models have lost their relevance. The main advantage of such structures is as follows: almost anyone can make wooden windows with their own hands.

Benefits

To date, wooden windows with a double-glazed window are considered an elite option who can afford not every homeowner. According to its technical and operational characteristics, they do not extend the PVC structures at all, and in terms of environmental safety, they are largely superior.

The undoubted advantages of wood models include:

- naturalness;

- safety in use (do not release toxins during temperature drops, with high-quality installation do not change their parameters);

- simplicity and ease of installation, repair work;

- Aesthetic appeal (on wooden models almost invisible dirt);

- Several opening options, mosquito net.

Of course, such structures are not cheap. But make them with your own hands - the way to save.

Made on special windows of wood windows distinguishes the accuracy of the assembly. But the observance of all technological features of the compound process of various design elements will make it high quality and reliable.

Instruments

To make such a window with your own hands, you will need such tools:

- drill;

- a hammer;

- screwdriver;

- milling machine;

- roulette;

- line;

- Strapboard;

- glue;

- sealant;

- Fasteners.

Ku

The greatest popularity among materials for the manufacture of the box in consumers of the middle class uses pine. It is available in the price plan and is practical in use.

High quality will be a window of oak. But this material is quite expensive, so specialists are not recommended to make a window structure from it for the first time. Also do not apply soft wood species.

Pine boards, which will be used for the box, need to dry correctly.

Council

When buying a board, choose the material without bitch, cracks, undeformed. The box is experiencing the greatest load, so it must be made of high-quality board.

If the glued bar was chosen, then if you are guaranteed to get a high strength window, you will not change its parameters during operation.

Article on the topic: Bamboo canvas for walls How to glue (photo and video)

To avoid subsequent deformation, the window block must be a pair of centimeters less open.

Depending on the thickness of the window, the timber is selected. The minimum indicator is 6 * 4 cm.

The grooves in the timber can be done using a mill or electruruck. Before carrying out this stage of work, it is best to practice on a separate piece of blackboard.

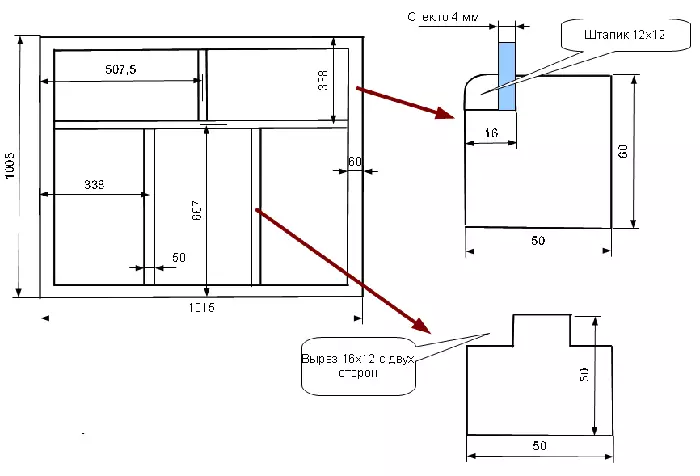

First, it is necessary to make measurements, according to which you can make a box. In the workpieces to it to a depth of 1.5 cm, grooves should be made, having the shape of the letters of the first ends of the bars bequeered at an angle of 45˚. After that, all the elements of the window box must be joined with a joinery glue, make holes in them through which to insert rods from a tree with a length of 3 cm.

Council

Do not forget to lubricate the hole with a hole under wooden rods.

Thus, the resulting design will become fixed and rigidly fixed at right angles.

The opening in which the box will be mounted, it is necessary to pre-prepare: clean from garbage and dirt, align. In the walls, drill holes (with a step of no more than 80 cm) in which you need to drive the dowels. The box is fixed using selflessness.

After that, with the help of a mounting foam, it is necessary to close all the slots between the walls and the box. The advantage of such fixation is as follows: the design does not depend on temperature differences.

It must be remembered that the window geometry should be clearly observed: angles - 90˚, the difference between diagonals - no more than 10 mm, deviations in flatness - no more than 1 mM per 1 m window of the window block.

Frame

Specialists advise to measure the frame to invite professional masters, since the slightest error in calculations can lead to undesirable consequences. It is best to make a frame from a bar with a cross section of at least 6 * 4 cm. For Eurocon, a bar is needed, the humidity of which does not exceed 12%. Oak, Grab, beech ideal for such designs.

Council

It is worth applying for the manufacture of frames of solid pieces of timber, it is better to make it from several boards in several layers, connecting each of them with joinery glue; Make sure that the fibers of each layer are perpendicular to the previous fibers.

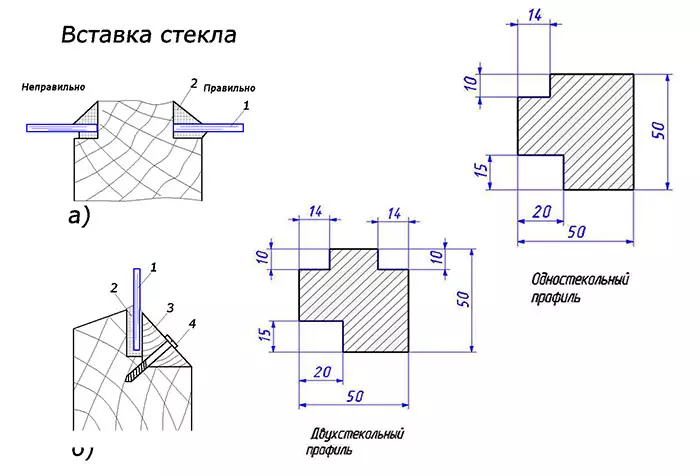

The amount and thickness of the glass, the stroke parameters depend on the shape of the frame profile. There is a pair of rectangular grooves in a single-setway model. Double-decker is an additional groove for the second glass.

Article on the topic: Homemade with your own hands

The shape of the profile is given by a milling or electrical ruble. In this case, the glass is 4 mm thick and a stroke of a thickness of 10 mm.

Prepared boards are collected, the corner of the cut across the edges should be 45˚. They are connected by the type of spike-groove and fix on the screws in such a way that their caps are recessed into the tree (if you wish, you can "hide" under the mixture of glue and sawdust).

Then the entire design is collected, the joints of the joints with joinery glue are thoroughly. After the frame is dry, the locations of the compounds are grief.

Window models with sash need to install accessories.

Council

Do not forget before installing both the box and frames, to process all the wooden components of the antiseptic composition.

Glasses can be mounted only after the frames are installed.

Installation features

In order for the wooden window to be installed strictly horizontally, mounting pads must be applied. The window is previously adjusted, then fixed with wedges.

Specialists are recommended for final installation to apply mounting plates. They are mounted on the window block at a distance of 25 cm from each angle. Wedges after that can be removed.

Council

If your window is more than 1.5 m, then install the additional mounting plate and in the middle of the design.

Glasses

It is important to correctly calculate the size of the glass, this will avoid the formation of cold bridges. The measurements are removed with an accuracy of 1 mm. When cutting glass with a diamond self-tapping screw, it is necessary to take care of the safety technique (use gloves to protect hands, glasses - to protect the eyes).

Prepared pieces of glass are inserted into the frame for fitting, then they are taken out. The grooves are applied to the grooves and the glass is inserted again. Then the entire design is fixed by the head with small carnations.

Latest strokes

Completely prepared design is installed in the grooves and fixed on the screw.

Council

Self-tapping screws should pass through the box, make it a mounting gun will help you.

In the last stage, it is necessary to close all the cracks of the mounting foam, give it to dry and shook the surface of the walls.

Article on the topic: Dryer for linen - Features and varieties

After that, you can mount the flows and windowsill.

As you can see, the manufacture of wooden windows is quite possible. Of course, for this you need to adhere to a certain sequence of work and comply with some technological subtleties.

If you doubt that you can make such designs yourself, seek help to professional craftsmen. They will manufacture and install wooden windows quickly and efficiently.