When repairing or building any premises, much attention is paid to laying a screed and the base for the finishing floor covering, which should be perfectly even strictly in the horizontal plane.

To assist in creating a smooth coating there are such devices like lighthouses for a tie of the floor. Lighthouses are called approximate structures that contribute to the creation of a horizontal surface.

Preparatory work before installing beacons

All dust and spots fungus remove before installing beacons

When repairs in the room before putting beacons for a sexual screed, it is necessary to dismantle the old finishing flooring. After that, remove all the plinths and get to the old cement-sand overlap.

The base must be cleaned of dust and mold, remove any stains.

In mandatory, it is necessary to carry out surface treatment with bioprotective and anti-grapple drugs. If there are cracks or destruction on an old screed, they need to be eliminated because nothing should prevent the installation of lighthouses for the fill of the floor.

After eliminating the defects of the old coating, the entire surface must be primed up for a good connection with the newly elevated screed.

Marking and determination of the zero level

To start, determine the zero level

Installation of lights for a tie of the floor should be made on the markup, applied to the walls of the room. Its proper application depends on the determination of the zero level.

To determine the zero level, it is necessary to determine the perimeter of the entire room on each wall and note the distance of 1 m from the floor (the mark must be applied at the place of measurement).

If we take into account that the room has 4 walls, then from four marks should choose the highest. It is possible to determine this with a laser or drip level.

From the zero level, drop by 1 m down - it will be the zero point

Regarding the selected point, it is necessary to place new marks on the walls on the walls and combine them into the line.

Article on the topic: Protection and impregnation of wood spent oil

Next, on the appropriate walls, you should drop from the new marking by 1 m downward, and put markup, which will be a zero point.

After determining the zero point of such a question: "How to set the floor level?", It should not arise. Before installing beacons, it is worth deciding on the thickness of the screed (usually 3-10 cm) and on the walls of the room are labeling.

Marks are made at the top of the zero line at the height of the flooded floor. By combining all serifs, it turns out the contour, by the level of which it is necessary to place beacons for floor alignment.

Remember that before installing beacons for a floor screed, it is necessary to clean the surface and pay great attention to the determination of the zero point. You should not neglect the implementation of accurate measurements and the implementation of hydro and thermal insulation, these works only contribute to the organization of good flooring.

Types of lighthouses and their installation

By asking yourself a question: "How to put lighthouses under the tie?", It is not worth a hurry with the answer. Many people can take a negligence to this issue and calculate that the installation of lighthouses on the floor is a trifling case.

For someone it is, but in any case, the screed without lighthouses will not work perfectly smooth. Therefore, to install the limiters and the choice of their species, it is serious that the installation is not reworked again.

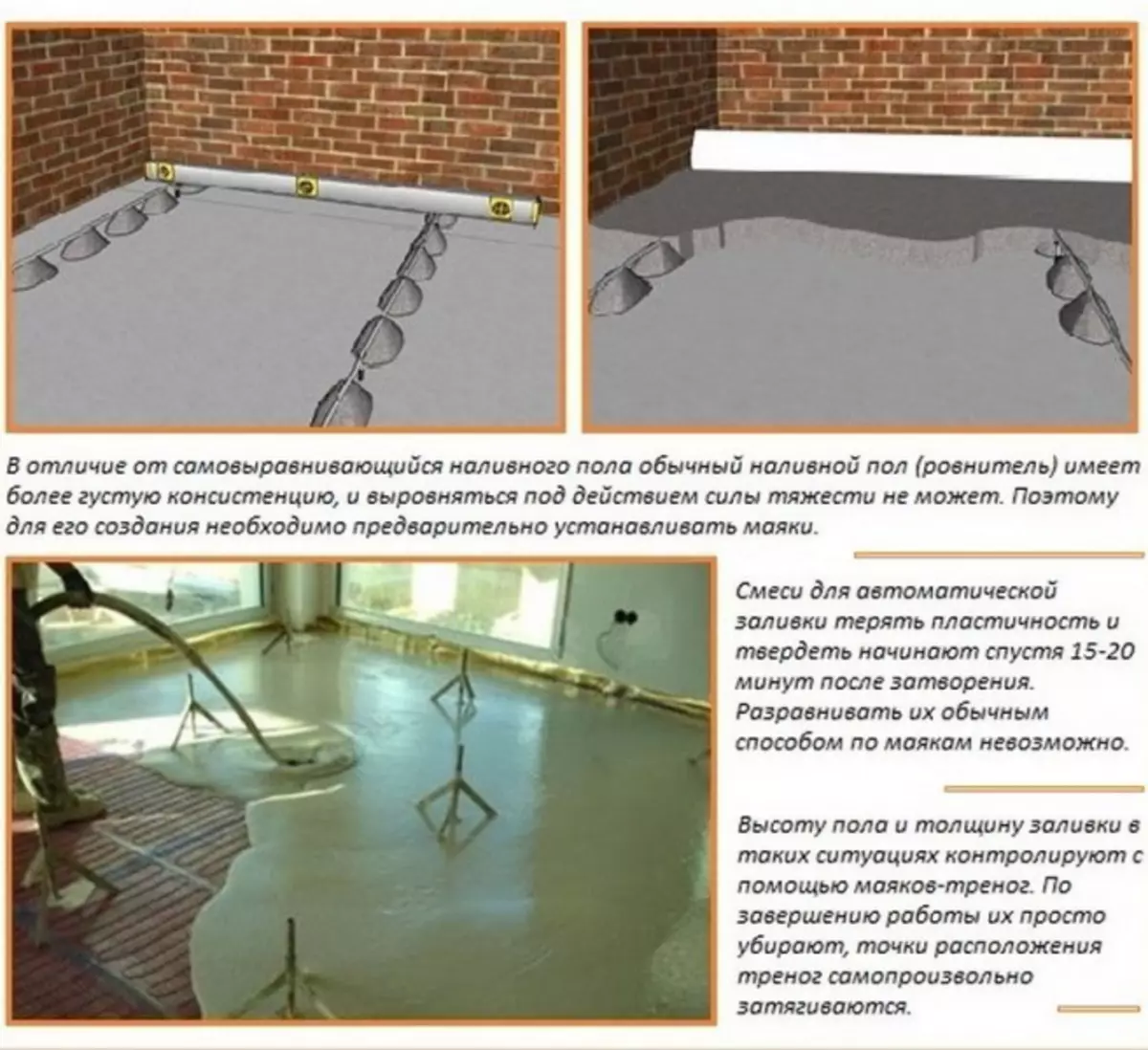

Lighthouses for bulk sex

Bulk floor for today one of the newest types of screed. When using this type of coating, many employees refuse to apply beacons to align the floor, since they believe that the self-leveling floor itself will take the necessary level, but not always it turns out.

Professionals strongly recommend pouring floor screed by lighthouses, especially since technology for this type of screed provides specially made referries. Look more in this video:

The reper is the modern view of the lighthouses under the screed, the production of which was able to put on the flow. It is a plastic trench with a retractable pin, which set in the middle of the product.

Article on the topic: how to sew a curtain tape: step-by-step instructions

The recommended step of installing the references is every angle m2. This means that if the overlapping in the room is to spread the grid with the intersection of the lines at a right angle, so that each cell will have dimensions of 1 m per 1 m, then at each point of crossing the lines you need to install the lighthouse under the tie of the floor.

The pin of each reper should be set to the level of the wall. Some time after the fill of the bulk sex occurred, lighthouses, or rather guide pins, can be dismantled.

Lighthouses for filling a floating screed

Such a flooded floor, like a floating screed, is gaining more and more popularity every year. Floating flooring should be poured with a concrete mixture after installing foam or polystyrex (polystyrene) on a draft base.

Before pouring the floor, the material is laid out on the waterproof surface, and the seams between the sheets are applied.

For this type of screed, the alignment of sex by lighthouses should be made using self-samples required length, and guides can also be applied. The benchmarks occur at one level with a mark, but before pouring the screed, it is necessary to check all lighthouses by the usual level or rule.

Mounting technology allows one day after the fill of the screed, remove the screws for the lighthouses by the lighthouses. Places of installation of landmarks should be lost to the solution and level the floor level.

Landmarks for semi-dry and wet tie

To date, these types of screeds are most often used in construction. Their organization is quite simple, and before putting lighthouses on the floor, the surface of the old overlap is grounded by an antiseptic.

Lighthouses for concrete tie

After mounting the limiters, the space is filling with a solution of a cement-sand mixture of various consistency (wet and semi-tie).

For the organization of such coatings, different guidelines are used, but the most popular applications that have received a wide range of applications are considered to be the beacons of a suction type from a solution with fixed guides in the form of a metal profile. All the subtleties of the process, see this video:

Article on the topic: Flooring Popup - the best option for sports grounds

Before making a sticking floor, supports from a small size solution are exhibited on the primed surface, which can keep the guide at the wall level.

After installing the landmarks should be left to complete drying

Then, the profile strips are installed on the supplied support element with marking. The distances between the guides depend on the size of the rules applied and the scale of the room.

After correctly put the benchmarks of this type, it is necessary to give them to frozen (1-3 days), after which the pouring of the floor screed can occur.

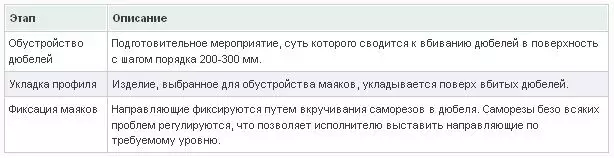

Concrete lights are still used on dowels. The principle of setting the landmarks of this type and the procedure is indicated in the table.

Application of lighthouses for dry screed

The dry screed of the floor by beacons is made using various bulk materials, it is usually slag or clay. As a landmarks for such a variety of screed, it is advisable to use wall metal profiles for drywall.

Its thickness should be like an estimated layer of screed (or less than 1 cm). Such an installation of beacons on the floor should be reliable and rigid, since there will be a heavy bulk material between the profile-guide, which at the time of the formation of concrete is able to crush and deform the metal. On how to perform a dry downtime by landmarks, see this video:

It should be known that when organizing beacons using a solution from a solution for guides, many builders do not want to wait a few days before the period until the cement-sand mixture will be free. To speed up the drying process, it is possible to mix the alabaster with cement, which will undoubtedly reduce the dying period of the landmarks and will provide an opportunity to carry out further work.

Based on the above, we can say that the correct installation of beacons to the floor is a responsible effect. Since, quality installation of landmarks gives great chances of receiving an excellent result in the form of a well-performed work on the pouring screed. Creating your false floor, you should not hurry, perform all the above events, and the result will not make yourself wait.