Traditional natural wood floors are beautiful in all respects - they are environmentally safe, easy to install, beautiful and practical. However, from all materials, wooden boards are most susceptible to various deformations.

So, during operation, almost in any wooden floor appear gaps between the boards. These gaps contribute to rotting, through them a large amount of heat breaks, dust and dirt accumulates in them. If the gaps appeared, they must be seal. How best to do it?

The reasons for the formation of slots

The gaps between the gender boards can be formed due to a variety of factors:

- Temperature deformations. Due to regular temperature fluctuations, the tree dries, the joints of the coating elements become wider. It avoids this helps material dried at a plant with a special method, in which all water is removed from the tree cells using a vacuum. The usual boards dry for several years and during this time they change markedly in size.

- Rodents who spoil wood. Just close the flaws in this case are not enough, it is also necessary to get rid of mice or at least not to give them to break the floor, starting the cat.

- Errors when laying boards. In this case, you need to securely fasten the coating, and then it is already squeezing the gaps.

- Poor ventilation, as a result of which the tree rotates quickly. In this case, the joints should be equipped, you will need to equip the ventilation grille in the wooden floor.

Modern methods of repair

Shpaklevka

Shoot the slit in the wooden floor with putty is the easiest way, but this option does not differ in strength. If the boards continue to move during operation, the putty quickly cracks and have to do everything again. In addition, putty is very noticeable against the background of wood texture.

Article on the topic: Use of liquid wallpapers in the hallway and corridor

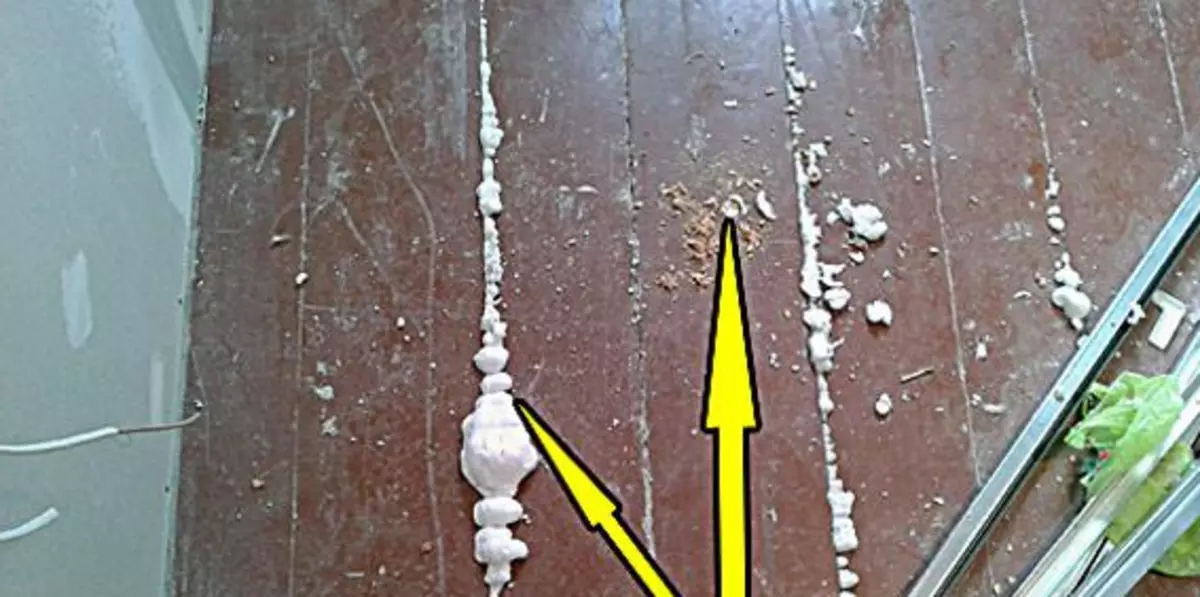

Sealant

If the gaps are dynamic, their lubrication material must also be movable, having good elasticity. To ensure such characteristics, sealants based on acrylic or silicone are used. The shuttering process is as follows:- The surface of the floor is cleaned and dried;

- The joints of the boards are filled with the mounting gun;

- The sealant is smeared with a spatula.

Silicone sealant can be selected suitable to the floor. Acrylic-based sealants are also an excellent option. They are resistant to temperature fluctuations and high humidity, easily polished, they can be painted and varnished. The tensile strength is very high - the slot can stretch twice without losing the integrity of the sealant.

Mounting foam

Close the joints of the boards in the floor with this substance is very simple. We need only a special pistol and plastic soft tube, which is compressed and shoved in the slot. Foam should be applied evenly and with a small pressure. It is necessary to act quickly, as foam hardens almost instantly.

The narrow slot can not be lured from the inside, but causing a foam from above. It is necessary to smear the foam not a spatula, since the material to the metal is tight. It is better to use a wet wooden bar, lubricated with soapy solution. Surplus foam are removed by the stationery knife after drying.

The disadvantages of foam is its ability to collapse under the action of ultraviolet, porosity and attracting dust. But the layer of mounting foam works well as a heater.

Scotch

If an additional finishing coating layer will be lying on the wooden floor, and the attractiveness of the seams is not important, you can simply flush the joints with a construction wide scotch. His edges are fasten with a board with a stapler. Scotch perfectly protects the room from drafts and flowing through the butts of the cold boards.Traditional methods

These methods of sealing gaps are tested by time and often turn out to be optimal.

Article on the topic: Cross-embroidery Patterns and ornaments Schemes: Geometric free, Celtic folk ornaments, black and white

Wooden rails

Close the rack is very simple. Technology method is such:

- The edges of the boards are processed by a manual cutter.

- Suitable rains are cut. It is best to take pine boards, as they are easier to process.

- The edges of the genital board and the side faces of the rail are lubricated with adhesive mortar.

- The rail is inserted into the gap and fixed reliably. The remaining intervals can be sealing the mixture of glue with sawdust.

- The resulting surface is polished with a ribbon grinding machine or manually. It needs to be protected by glasses and a respirator, as a lot of dust will be formed.

- A stalk pasted painting tape.

- The renovated floor is painted and covered with varnish.

- Putty of girlfriend

An old recipe for putty, according to which you can make a smear with your own hands, is a sticky composition of wood resin and sawdust.

You can also mix sawtresses with PVA glue. The resulting mixture is perfectly connected with a tree, and after drying it becomes very solid and durable. Minus only in the roughness of such a putty, to give a decent appearance will have to thoroughly treat it with emery paper. In addition, this material darkens during operation.

Similar recipe - a mixture of varnish and wood dust.

Floor sewing plates plywood, chipboard, drywall

You can apply other similar materials. It is recommended to close the jokes of the boards in this way in the case of very wide gaps that no longer smelled. On top of the layer of plywood sheets or other material it will be possible to put any decorative coating.

On the old wooden floor, a frame of miniature lag is formed. To do this, it is necessary to apply a ram from durable wood. Bruces are installed in a step of 60 cm, depending on the thickness of the sheets of the coating. Under these elements, it is necessary to lay the pieces of linoleum or rubberoid to absorb the load on the floor.

Article on the topic: Screen under the bath - Stylish and effective solution

It is worth considering that if the distance between the frame elements is to make too large, the floor strength will decrease. The sheets of plywood or chipboard are attached to the frame with the help of self-tapping screws, the hats of which need to be dragged into the material or at least to do to the surface. Instead of self-tapping screws, you can use glue into a pair with nails, so also sufficient reliability of the coating will be provided.

The gaps in the frame can be filled with insulation - for example, mineral wool. Between the plates you need to leave gaps for deformations, otherwise the floor will creak. After the installation is completed, all the joints and spuns of fasteners are closed with putty. After its drying, the floor can be lacquered, painting or retarding the finishing coating layer on it.

Cord

This method is the fastest. Its essence is that a simple rope is stacked in wide slots in the wooden floor, which is then poured with a solution of epoxy resin with cement. After hardening the mixture, you can paint joints.