Cooking in the oven conveniently, you do not need to spend a lot of strength to prepare lunch. It is enough to place a container with the products in the oven and get a ready-made dish.

But this convenience also has the opposite side of the medal - the surface of the baking compartment is contaminated, coated with soap and fat and extrude them is not easy. Today manufacturers offer consumers units equipped with various self-purification systems.

To understand this manifold and find out what kind of cleaning the oven is better, difficult. In this article, we will look at what types of self-cleaning are present in modern windscalkers.

Traditional cleaning oven: what it is

Traditionally, to clean the oven use detergent and sponge.

The traditional cleaning system is called ordinary, "grandmothers" methods. Sponges, special powders and liquids, as well as folk remedies for removing Nagara apply here. The disadvantages of this method are obvious:

- time spent and labor complexity;

- the need to separately clean pallets and lattices;

- Risk of damage to surfaces.

The benefits are only calculated by electricity savings and low cost of plates that are not equipped with a self-purification system.

Emale easy cleaning oven: what it is

Special coating allows you to easily wash the surface of the oven.

Emalty of easy cleaning is called a smooth coating of the inner surfaces of the oven, on which there are no pores. Fat and soot can be removed, the walls of the wall with a cloth.

Such a coating relieves the hostess from the need to clean the oven for hours, but still does not exempt from the washing of surfaces by hand.

Article on the topic: Ball from paper with your own hands: Templates with video and schemes

Hydrolysis or catalytic cleaning oven: what it is

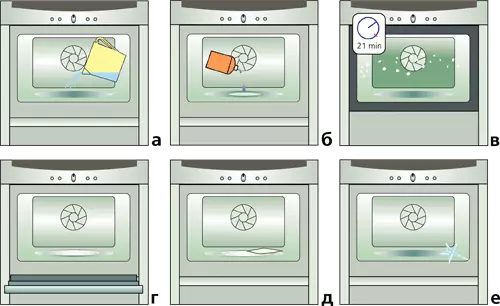

As the name implies, hydrolysis purification is dissolving contaminants under the influence of water vapor.To put in order the oven, it is necessary to put a baking sheet in the compartment, and under the condition of strong contaminants, with a solution of detergent. After that, the unit includes and warming up for 30 minutes. If necessary, water has to be treated.

As a result, pollution softened and after the oven cools, it will remain rinse the surfaces, lattices and bars in running water, and if necessary, clean the sponge. Such a method requires much less time and effort than ordinary cleaning, but the need to wrapping with a sponge and messing down with an empty can be considered unconditional minus.

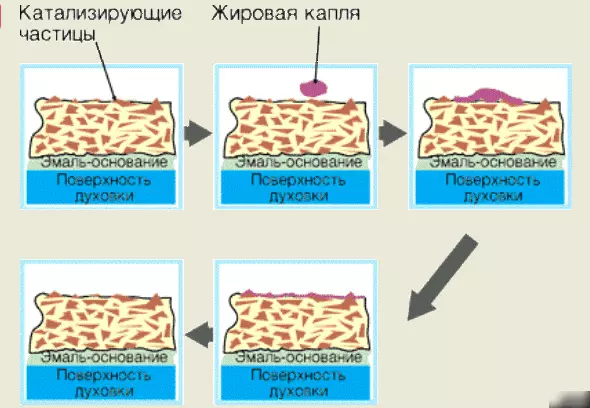

The catalytic method involves the use of special enamel for coating. This material does not allow fat to "eat" in the surface and harde it, which makes it easier to clean the brass compartment.

Cleaning the oven Ecoclean: what it is

Aggregates with such a type of cleansing appeared relatively recently. The walls of the oven are covered with special ceramics, when penetrating with fat, it is splitting, turning into water and carbon dioxide. This process occurs, provided that the oven is good warm.

In the case when the walls in the cooking of the walls were not clear enough, the empty oven 40-50 minutes and the surface would get rid of the plaque and the soot.

The main advantage of such coatings is the service life. The self-purification system is able to maintain a functionality of up to 10 years in regular use.

Pyrolytic or catalytic cleaning oven: what is better

The pyrolytic method is considered one of the most efficient. Such cleaning is simply indispensable if the oven is often used.

Under the influence of high temperatures, fat simply burns, which leads to a complete self-purification of the oven. No additional effort is required from the hostess.

Article on the topic: Children's slippers do it yourself

The following factors can be specified as deficiencies in such a system:

- The required power of 6 kW wiring;

- high electricity consumption;

- Strong heating oven for cleaning (up to 500 °) and heating directly entire unit.

When using this method of purification, it is better to somehow protect furniture, which is located next to aggressive impact.

With a catalytic method, electricity consumption is not as large. Special enamel contributes to the oxidation of fat with its subsequent splitting, which greatly facilitates cleaning. In addition, it is possible to clean the surfaces in the cooking process, which you can not say about the previous version, since there is a very strong heating.

However, catalytic systems are not eternal and covered with enamel, have to change. They are designed for 300 hours of operation. In addition, the panels protect only the walls of the compartment, and everything else will have to be cleaned manually.

So, what is better: pyrolytic or catalytic cleaning of the oven? It is impossible to give an unequivocal answer to this question, it all depends on the frequency of operation of the baking compartment. If you are cooking in the oven very often, it will be stuck too much. In such a situation, pyrolytic cleaning is the best way out.

But if you use an oven occasionally, for what excess costs? The catalytic system will perfectly clean the unit.

What cleaning oven is better catalytic or hydrolysis

As mentioned above, hydrolysis is a method of cleaning with the help of water vapor, and at a catalytic surface system, the surface is getting rid of plaque and in the expense of the panel coating features.

And the other method is used not only in electrical, but also in gas units and this is a plus.

Continuing a comparative analysis, it can be said that hydrolysis allows you to save money (there is no need to purchase cleaning agents), and a catalytic method - physical efforts when laundering surfaces, because fat neutralizes. In addition, through time, the catalytic panels will have to be changed.

Article on the topic: Openwork napkin Crochet: Scheme and description with video from YouTube

Which way is better - to solve the hostess, in this situation it all depends on personal preferences.

What is better: catalytic cleaning of the oven or purification by steam

Catalytic cleaning is carried out directly during the cooking process. You do not need to further launch the oven and spend electricity to get rid of fat and soot on the walls.As for the purification of the ferry, the situation is different here. The principle of operation of such a system is that the fat and the raid soften under the influence of steam. To do this, it is necessary to place a capacity with water inside the compartment and warm the oven for a while. Complete this process with cooking does not work. You will have to wait for the end of cooking and cooling surfaces.

If we talk about financial costs, the catalytic system will cost you more, since the panels will be required to be changed periodically. Yes, and when buying an oven for such an option, you pay more than the unit with a ferry cleaning function.

What type of cleaning oven is better

What type of cleaning the oven is the best? The answer to this question everyone finds himself. In some cases, you save time, and in others - cash and electricity.

Considering the various options for making a final decision, find a response to the question: What is more important, saving or own comfort? What is the best for you, pay more and acquire an aggregate with pyrolytic cleaning, so as not to worry about the condition of the oven, or to invest less funds, and at the same time apply forces when you hover purity?

If you use the oven from the case of the case, it is necessary to clean it infrequently and is quite suitable for an economical option. But in any case, the choice remains for the hostess.