Concrete screed has one essential disadvantage - it is too cold. Because of this, the screed process needs to take care of its insulation, which significantly increases the cost of work. Recently, a solution called a polystyrene polybetone has become widely used.

It has cement and polyfoam granules. Pouring polystyrenezlibetone is a fairly simple procedure, moreover, if you wish, you can easily make a mixture yourself.

In this article, we will tell how to properly carry out a polystyrene insulation procedure, as well as consider the composition and main advantages of this solution.

Composition of polystyrene bonts

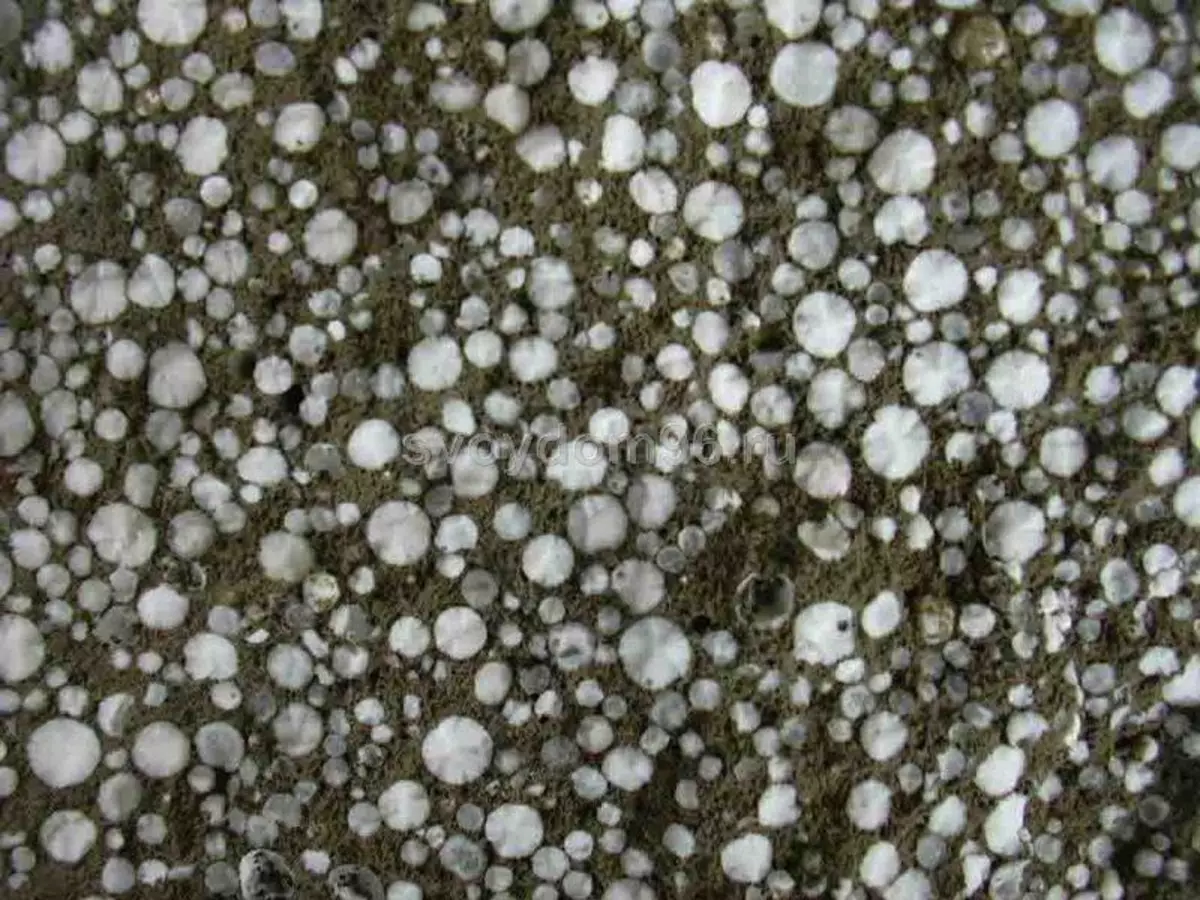

Pelonoral granules are filled in this mixture instead of sand and crushed stone

The solution is approximately 85% consists of foam pellets. Thus, polystyrene granules act as a filler, while replacing the crushed stone or sand. Portland cement is added to ensure viscosity. Also, sometimes add washed sand.

When mixing the solution, it is necessary to add a plasticizer, this will increase the indicator of plasticity and prevent polystyrene float. You can use a substance manufactured for these purposes or any detergent solution. The second option is more often used during self-preparation.

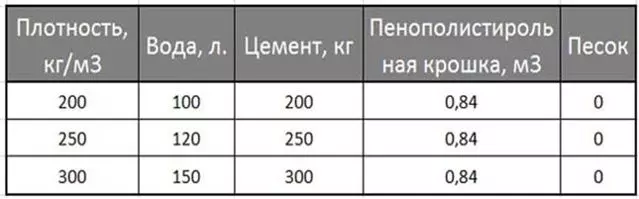

In the following table, you can see the proportions of polystyrene concrete, depending on the cement brand.

The ratio of substances depends on the task for which the material will be used. Polystyrevbeton is used for many procedures in construction. It is used for closing floors, buildings of various types of buildings. Also, this solution is often used to fill the foundation.

To create a mixture, it is recommended to take polystyrene granules, cement and water in a proportion of 840: 200: 100. The resulting solution is used to create a screed, followed by a coating flooring.

For public premises, the share of cement will be needed to increase to 300 kg / m3.

Article on the topic: how to repair the dripping crane

Making a mixture yourself, it is quite difficult to properly observe the ratio of substances, but on the quality of the solution, this factor does not have a strong influence.

Advantages of polystyrevbetone

The solution has quite a few advantages that will help when creating a base for the floor or construction of different types of rooms. The main advantages of such a mixture include the following characteristics:

- Low thermal conductivity indicator, so additional thermal insulation will not be required.

- The small weight of the designs produced, which will help with the construction of high-rise premises. Due to the small mass, the pressure on the foundation will be reduced.

- Due to the high plasticity of the material, the concrete practically does not give a shrinkage. This allows you to prevent surface cracking.

- The cost of the mixture is rather low, especially if it is made independently.

Disadvantages of polystyrene bonts

Polystyrevbetone is not famous for strength

The minus has only one material, but it is quite essential. The polystyrene floor has low strength and weak abrasion resistance.

Because of this, the surface will be needed to further strengthen. If the use of a mixture for walls is planned, an additional surface cladding will be required both inside and outside.

Such material can only be used for residential or public buildings. For technical premises, if necessary, it is extremely recommended to use such a composition. Inside the room will also need to take care of the protection of the upper layer or Topping. For more information about the quality of the material, see this video:

Topping will not need only if the tile will be laid in the future. The adhesive mixture and tile will provide the required level of protection for the surface.

Toppings apply to strengthen the surface of the screed

For the remaining types of floor covering, the surface must be strengthened.

If work is carried out in the public space with large loads, Topping is done using special solutions. When the screed is made independently and in the future laying of flooring, we recommend producing a looping chipper. It must be done after the polystyrene beeton is partially grabbing. Such a procedure will help:

- Partially strengthen concrete;

- Finally align the surface that is a key requirement for further coverage flooring.

Article on the topic: Ventilation grilles with adjustable blinds - beautiful and practical

Polystyrene-based concrete

It is possible to mix the mixture with your own hands, but it is better to apply the concrete mixer.

This device will allow to significantly speed up the procedure, kneading will take about 10 minutes.

In addition to the concrete mixer, you need to prepare a bucket and a container for a mixture of the desired size. The list of materials to be involved is as follows:

- polystyrene granules;

- cement;

- Additives.

First of all, it is necessary to pour water into the concrete mixer and fall asleep cement in the 2: 1 ratio. To increase the plasticity on each water bucket, add approximately 20 ml of detergent. For details on the preparation of the mixture, see this video:

Polystyrene is added in minor portions until the mixture will receive the consistency you need. The proportion to water should be about 1: 4. When pouring a bucket of water, you will need to add half the cement and about 4 buckets of polystyrene.

Consider that the taking time of concrete in light cement will be reduced. If one is planned, it is necessary to follow the polystyrene batter after the fill.

Pouring and alignment

The screed is performed on a wet surface

Filling the floor with polystyrene fiber is fairly easy to produce, the technology is similar to the procedure for ordinary concrete.

First of all, it is necessary to clean the surface from contamination and dust, primed cement and treat with water.

Floor screed is performed on a wet coating. Over the perimeter of the surface, beacons are installed that will help determine the level for the screed. Then the mixture is then aligned. After the day, the beacons are dismantled, and the holes are treated with a mixture of expanded polystyrene foam. Due to the rather difficult procedure for aligning this material, it is used only to create a base, the thickness of which does not exceed 3 cm. The overall thickness of the screed may vary depending on the type of construction.

It will take care of the tie during the frost, for this during operation it will be necessary to attach a polyethylene film. Then the solution is left to dry and gain strength of 5 days. To get rid of extra moisture, the solution is left outdoors for 2 weeks. For details on the screed of expanded polystyrene, see this video:

Article on the topic: Living Room Interior Design

The final processing is performed using a cement-sand mixture, while its thickness does not exceed 5 cm.

As you can see, it is quite simple to make a screed from polystyrene. The main thing to adhere to the basic rules and recommendations. It is also recommended to use high-quality equipment and materials, because it is from them that will depend on the result of your work.