The sofa is furniture that is always necessary in the interior. Furniture stores do not so often offer those types of sofas or other products that would come to the interior design. It is possible that the owner himself has skills in the manufacture of furniture, so it can afford to realize the desire to make furniture to the house independently.

The sofa is an integral part of the interior. And if the store offers high prices for this furniture, it can be made with your own hands.

It should be envisaged that various tools will be needed to create a sofa. Prepare them, make a sofa in size and its own taste can be their efforts. The product will be made according to an individual drawing, which is associated with its uniqueness.

Then may come to the aid of resourcefulness, grip, skill and knowledge of a carpenter, to create an independent masterpiece. At the same time, it can be known that the use of materials in the process of creating a sofa will not be associated with major cash spending, as when purchasing it, taking into account the coloring of the trim in its own taste.

Determination of the design of the future product

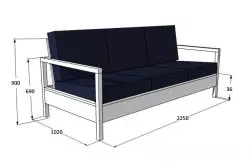

Overall dimensions of the sofa.

Before starting work on creating a sofa, it is necessary to design its external image, and then develop furniture design in the room as a whole. At the same time, you can come up with the design of the angular sofa, which will be suitable for the main furniture. It should be borne in mind that at home is difficult to produce high quality sofas. You can make the corner sofa itself by making the frame mounted on the stand or legs of the product.

From time to time, the mechanism of the roller system is used. Due to the folding seats of the sofa, you can have special access to all its niches from the side of the sides. Niche will be mounted in the form of small boxes, and then installed on the sofa at their own discretion.

Schedule the size of the product must be carefully because it may not fit in the prepared area of the room. All countable dimensions are chosen by relying on their own taste, addiction and size of the room. At this stage, it is necessary to prepare a drawing in advance to create an ordinary or angular sofa.

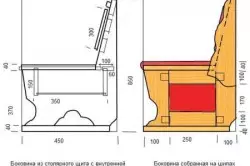

Soft sofa scheme in section.

Next should be visited the building materials store. For beginners performing work related to the installation of the sofa for the first time, the most convenient solution will be the design of a folding structure, not an angular. The product frame should consist of a frame that has a rectangular shape mounted on legs, taking into account all suitable sizes.

Article on the topic: Tile for the kitchen on apron: expert recommendations

For the creation of the frame, the bars are used, the best material for the manufacture of which is pine. Self-tapping screws are used for mounting timber. Fasteners should be performed so that cracks do not occur. Press the sofa frame is maximum strength by screwing each bar in cubic shape to the corners of the frame.

Self-tapping screws are suitable for attachment. The bottom of the sofa will consist of plywood, the size of the sheet should be suitable for the framework of the frame. Phaneur can be kniting with nails disposed on the same level. Make a sofa can be based on the execution of work in three stages, which includes:

- Buying materials.

- Preparation of instruments.

- Creating a frame (frame).

- Upholstery of the product.

Consider each of the steps more.

Phased creation of a sofa

Required materials for the manufacture of the product

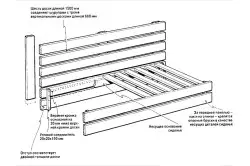

Sofa frame scheme.

It is possible to make a sofa itself without the use of special and additional types of material, a bar of pine and plywood is perfect here. First, the product must be designed in detail on paper. It is necessary to carefully consider any part, for example, the level of inclination of the back of the product, a certain size of the height of its legs, the overall dimensions of the structure as a whole, etc.

It is necessary to take into account that the entire load from the product will be on the feet of the sofa and its back, the base should be durable. The back and seat should be provided for appropriate strength, the legs of the product should be fixed fixed on the frame. It is necessary to take into account when creating a sofa that the pine timber is prepared taking into account the corresponding size of 60x60 mm, and the plywood sheet thickness takes equal to 12 mm. These types of materials are the most common, as they are associated with an affordable offer at an affordable price.

Among all the fasteners can be allocated: self-tapping screws and steel corners. The necessary tools will be a screwdriver and saw. Sofa is better using a foam rubber, tapestry or synthetic procession. Strengthen the material with the help of lightning covers. You can make a frame from bars that differ from more solid wood species without any additional flaws. All elements of wood must be lacquered, saving the appearance of the tree.

Where to start an assembly of the sofa design

Sofa details scheme.

Among the main elements of the sofa, you can allocate:

- Railing.

- Pillows.

- Frame.

- Legs.

Production of the sofa can be conditionally divided into four stages.

- Assembling frame. For a frame or wooden frame, you need to prepare a bars that do not have visible flaws and are smooth. You can make them from those breeds that are more durable. Prepared tools produce broke Bruschev. Further begin to fasten the frame. If only the screws are not enough for attachment, then it is best to use each connection to the non-toxic adhesive for the tree that is most suitable for the selected material.

- Making seats and sofa backs. You can make a sofa using a foam rubber, which is more economical. It is ideal and its analogues: holofiber or polyurethane foam. The final material has sufficient elasticity, but at the same time flexibility. He can quickly give the necessary shape, it is not able to absorb water. If the filler moves on the frame, then it must be glued to the frame.

- Sofa cover. For the trim, skin can be selected or tapestry, which seems more economical from options. It all depends on the wishes and financial capabilities. To seize the product, you will need a construction stapler. Prerequisites material, its edges are processed. Then you should give the appropriate fixation of the trim on the details of the product from the tree, that is, its frame. It is enough to sheathe the sofa times, and later it will not be necessary to spend all your means to spend on its secondary tightness. All work is really done without helper. You can cover the sofa. Another option will be the creation of special covers for the sofa. At the same time, it is necessary to provide for the presence of soft seats representing pillows.

- Final processing. Each visible wooden sofa element is better to handle the veil and varnish, for which all materials should be prepared even before the start of the frame assembly.

Article on the topic: Hiking saw from prudent drugs with their own hands

Using a bar and plywood for maccas

Sofa sofa scheme.

You can prepare the whole set of tools yourself, it is necessary to provide for:

- Hacksaws.

- Drills.

- Mill.

- Screwdriver.

- Roulettes and centimeters.

- Pencil.

- Line.

- Emery paper.

- Scissors.

- Cutter.

- Stapler construction.

Without taking into account steel fasteners, glue is used, allowing each of the parts to firmly and high qualityly combine each other. This will make the design tighter and safer. Each connection is necessary to skil using suitable glue. It should be perfectly suitable for a wooden product. Otherwise, there will be uncomfortable to rest on the sofa and sit.

Sofa upholstery scheme.

It will be necessary to make an assembly of a sofa from a bar, creating three frames having a size equal to 72x1860 mm. Strengthen the angular parts can be similar, and the installation principle is associated with a spike on glue. Of the two frames make the base of the sofa. The frames must be combined with each other by four bars of 60x60 mm and about 200 mm long.

The gluedboard will be required, which is stacked in that part of the sofa, where the mattress will be. Be sure to strengthen the loops to the frame, and the third frame should be covered by the board, like the sofa side walls. The back of the product should be fixed to the wall by 5-6 loops, which will guarantee the product the required level, the carrying capacity of which is from 150 to 200 kg, the back should be relying on both sides on the rack, if it is decomposed.

When the manufacture of the sofa seat is already completed, proceed to creating a frame backing frame.

This can be done while respecting the relevant stages, the same as when creating the seat of the product. If the sofa folding model is required, it is best to fix the back of the product. This can be carried out using reliable corners made of sufficient thickness. Specialists are not recommended to make a back strictly vertical.

Article on the topic: Cases of walls Plasterboard in the bathroom with shelves and niches

Finishing work independently

The sofa work surface will be needed to put up the upholstery fabric and filler to make the sofa soft.

Before tosing a sofa, the cloth must be pre-performing any of the sharp corners using sandpaper, as otherwise they are able to break the fabric. Then proceed to the creation of the basics from the foam rubber. It is necessary to persuade the basis using the tapestry. At first, the foam used must be wrapped with syntheps, and then connect these materials by applying zipper.

At the end, fastening the foam rubber to the framework of the future product. Pre-foaming is placed in a stitched case of tapestry. This feature is made at the expense of the velcro tape, one part of the tape should be attached to the product, and the second must be attached to the tapestry.

We will not know the reminder of the trim of each edge, which will speak a little for all the edges of the seat and backs. To hide Velcro ribbon, the stripe of lightning will help to remove the cover for washing. From time to time it is attached to the product of a foam rubber, which requires glue, but in this case it is impossible to remove the trim.

Performing final work

The residue of the synthet and foam rubber, and the tapesto is usually not thrown away, because these materials are used to create exquisite pillows for the sofa. They are perfectly combined with the product. The foam rubber can be attached to the back and seat. You can create a back and in the form of separate different pillows having a small size. They are placed on the seat, hang using special lipukets on the back.

One of the most convenient options may be the use of pillow covers, sofa backs, its seat. This will help to predict the replacement of covers to be able to wash them, supporting cleanliness. The upholstery fabric over time covers wrinkles, as it is squeezed by soft furniture elements. Therefore, the basis must be wrapped with a vatin or syntheps.

To add the interior with a new sofa, you can sew beautiful curtains, install suitable lighting devices, sew special pillows to the sofa. If you try, putting even effort and patience, you can create a coffee table, putting it next to the new sofa.