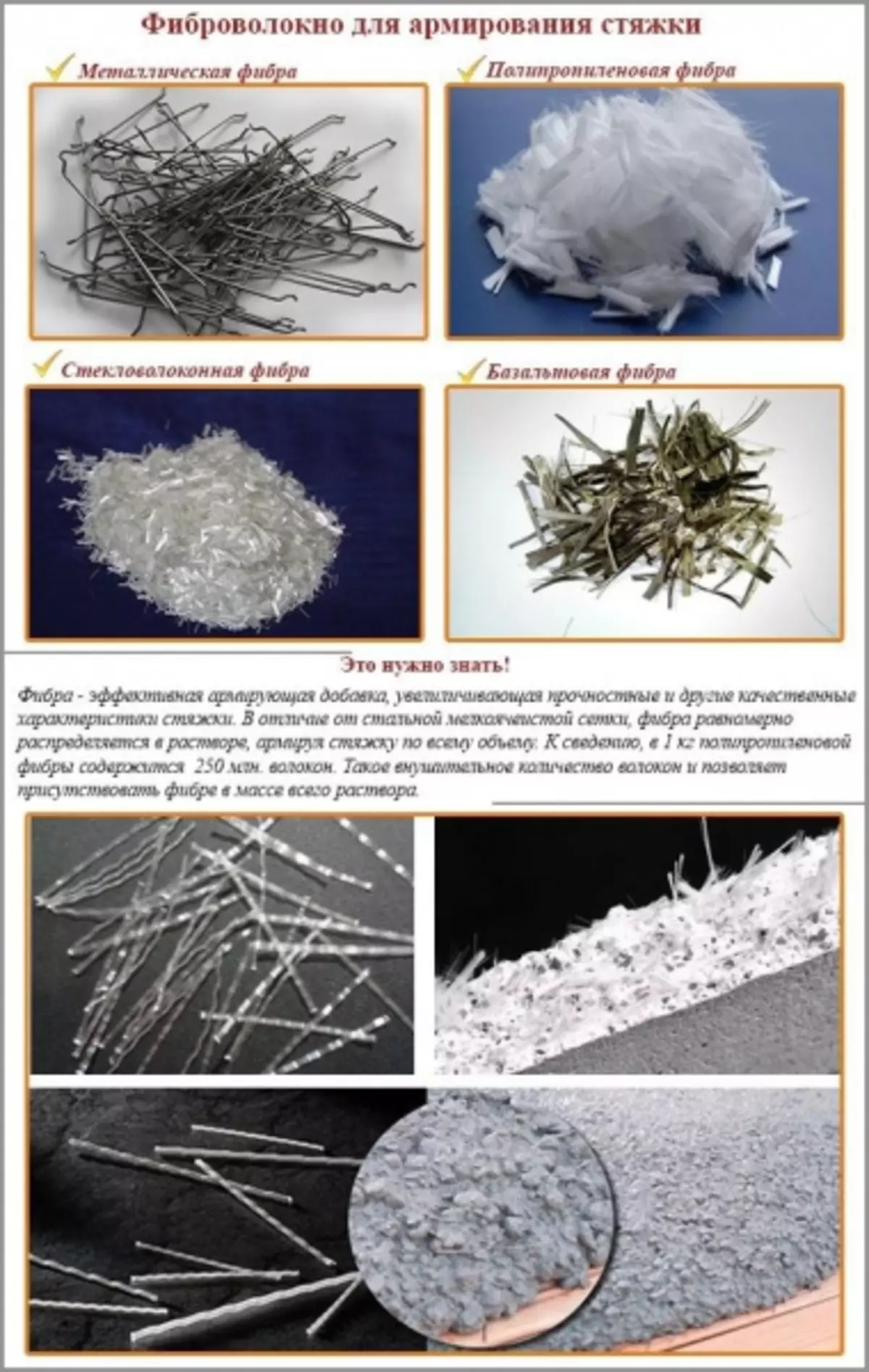

Fiber for a tie of the floor is made of propylene in the form of a fiber translucent white shade, has a diameter of 15-25 microns. For better adhesion with construction materials, it is impregnated with oil substance.

Due to the use of material reinforced fiber, the stability of the base to abrasion increases, the surface withstands more freezing / thawing cycles, eliminates the occurrence of cracks and moisture penetration.

Fiber characteristics

Polypropylene fiber for a screed is a full-fledged substitute for metallic reinforcement.

It has many advantages compared to metal fiber.

The comparative characteristic of fiber fiber and metal for reinforcement is given in Table:

| Fiber | |||

|---|---|---|---|

| Indicators | Polypropylene | Metal | Basalt |

| Destruction under the influence of humidity, corrosion | Not subject to | Susceptible | Not subject to |

| Electrostatics | Not electrified | Electrified | Not electrified |

| Cost | Average | Low | High |

| Strength | Sufficient (0.9-0.95 g / cubic meters), lower than that of the metal | High | The integrity of the foundation will continue even with the end-to-end cracking of the concrete solution |

| Use of indoors with high loads of gravity, with vibration and high permeability | Not recommended | Suitable | It is possible to use in seismically active areas, in the north, and in rooms with high humidity |

The longer the fiber, the more loads withstand the concrete

Fiber is produced in the form of a crumbly material, its fiber length is from 6 to 20 cm.

The length of the fibers affects the scope of application:

- 6 mm long fibers are used for cladding and masonry;

- Fiber for a concrete screed and construction of monolithic objects must have a length of 12 mm;

- During the construction of dams and other structures used under the conditions of an aggressive medium, it will take a length of 18 mm long.

When buying, you need to clarify whether there is a certificate on the products. If you buy poor-quality material, it will not perform the required functions, it can be distinguished into air harmful substances.

Advantages of fibrovolokna

The fibers are evenly distributed in the cement mortar by thoroughly mixing them, the reinforcement function.

Article on the topic: Step-by-step installation of the air conditioner with your own hands (17 photos)

Fiber improves the quality of the mixture, speeds up

Advantages when adding fibers to cement mortar:

- attaches strength, plasticity;

- Increases the life of the base;

- frost resistance;

- It does not burn, does not support combustion;

- protection against moisture penetration by reducing the pores in concrete;

- shrinkage;

- The term of soloing concrete decreases.

It is used to improve the properties of a concrete solution and the preparation of plaster compositions. Used in the construction of structures in seismically active and operated in an aggressive environment.

Mounting technology screed with fibrovolock

As with the installation of an ordinary screed, you need to prepare the surface, make the layout of the level of the black floor location, correctly prepare a concrete solution and perform installation, according to the described work technology.Surface preparation

We remove the old flooring, inspect the slab for the presence of defects, protruding reinforcement.

Sequence of preparatory work:

- Cracks are expanding with the help of a grinder, we clean their edges, close in a cement-sandy solution, mixed in the proportion of 3: 1. So that concrete is better grabbed, the surface is abundantly wetting.

- We remove dust from the plate with a vacuum cleaner.

On the perimeter of the walls, we glue the damper tape. It will perform the temperature seam function when expanding concrete during drying.

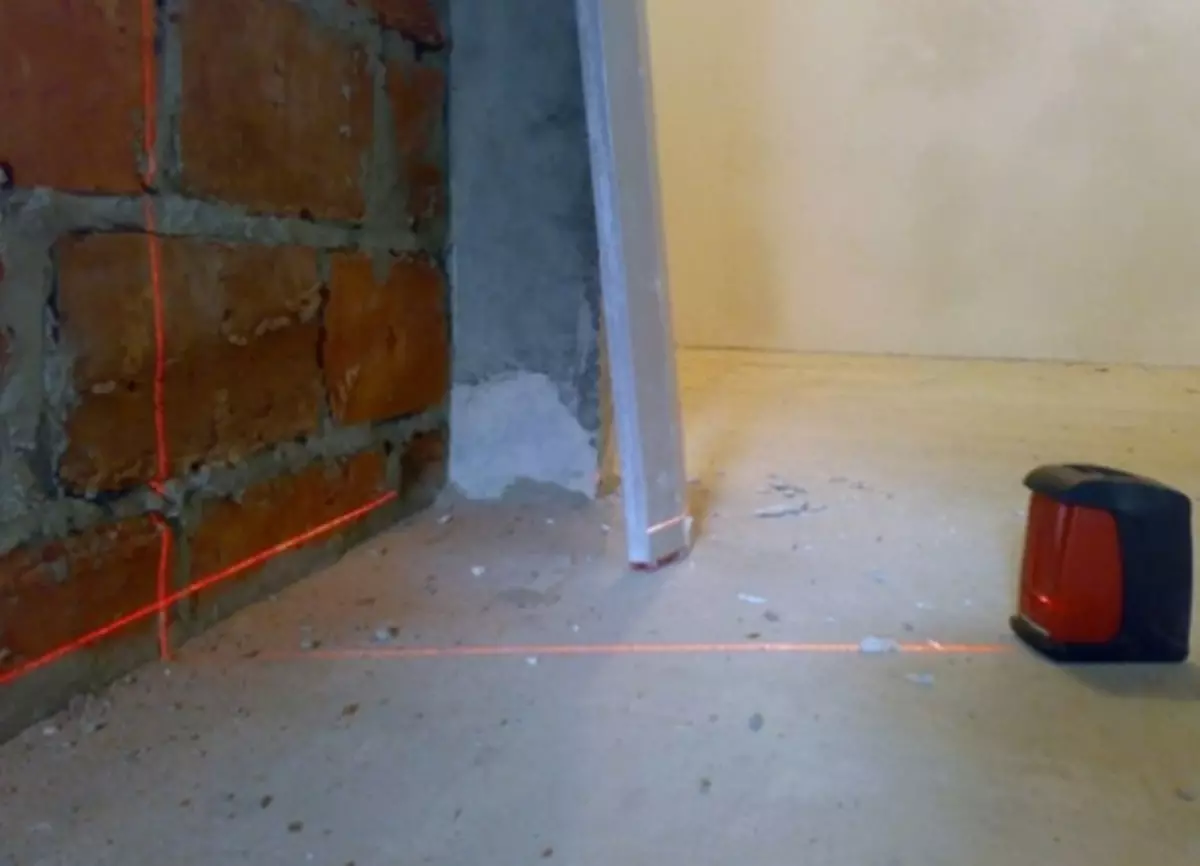

Marking level of screed

Before the markup, find the highest and lower floor points.

The thickness of the screed with fiber and the proportions of the mixed materials depend on the height differences and the functional purpose of the room.

We find the lowest and highest points on the floor using a laser or water level. We make a mark on the wall, blackcading a horizontal line at the height of the future screed.

According to the markup, we set the guides in parallel to each other in 15-20 cm increments. We consider that the distance between the beacons should be less than the width of the tool for the solution distribution. For details on how to do this with a laser level, see this video:

As lighthouses, we use smooth profiles, put them in a horizontal plane. To fix a certain height, we use bars or fix the beacons to the cement solution.

We check with a laser or bubble level correctly installing beacons.

Prepare the solution

Cooking a solution with adding fiber for a screed.

Article on the topic: How to fix pickups for curtains to the wall?

There are several methods for mixing components:

- Well mix dry components: cement, sand, fibrovolok. Then add them to water and stirred thoroughly to form a homogeneous mass of sour cream-like consistency.

- Fiber is added to cement milk, then injected into the prepared cement solution and mix well.

- Throw into a concrete mixer with finished mortar. All the subtleties of the zone process, see this video:

Preparation of a high-quality concrete solution with Fiber:

- Mix the dry components well with each other: 3 pieces of sand, one part of the cement. We add half the volume of fiberolok. Mix all the components.

- Take 400-500 ml water per 1 kg of cement.

- In small parts, add the remaining fiber and mix thoroughly.

The solution should turn out to be homogeneous consistency as thick sour cream.

We choose the cement brand according to the classification in the table:

| Brand concrete | Application | Consumption of cement in kg per 1 cube concrete |

|---|---|---|

| M 100. | The smallest strength is used for concreting borders, fences | 165. |

| M 200. | Applied when installing screed, foundations | 240. |

| M 300. | It has high strength, used for the installation of foundations, overlaps, etc. | 320. |

| M 400. | It has the highest strength, withstands bearing bridges and overpass | 417. |

Fiber consumption

The amount of fibers added to the cement solution depends on the requirements for the screed.| № | Fiber consumption | Characteristic tie |

|---|---|---|

| one | 300 gr per cube. M. | Slightly increases the binding function and makes it easier to work with the material. Such a proportion works like an additive, slightly improving the quality of the screed. |

| 2. | 600 gr per cube. M. | The plasticity, resistance to the penetration of moisture, strength and operation of the coating will increase significantly. |

| 3. | 800 to 1500 g per cube. M. | Maximum efficiency is achieved. |

The minimum consumption must be at least 300 grams. on a cubic meter

The ratio of the amount of fibers on a certain volume of cement is indicated on the package or in the filter instructions for the screed.

If you add too many fibers, they can provoke the formation of cracks and screed splits.

Fill the screed

Consider how to make a screed with the addition of fibra. Read more about Pouring a semi-dry tie with fiber from fibra See in this video:

Article on the topic: How to choose a boiler for water heating?

Works start from a long corner of the room. Paul should be pouring into one approach without interruptions.

Stages of work:

- Cement mortar with fiber pour to the floor between guides, spread the rules on the long handle.

- The mixture is compressed so that air bubbles come out and there are no emptiness left, with a needle roller.

- After a day, we take out the guides, poured a solution with a solution where they were.

We exclude drafts and cutting the surface. We cover the screed with polyethylene, every day we moisten the concrete so that the coating does not crack.

Nuances screed under the warm floor

Pouring the warm floor, use the same proportion to prepare the mixture as for the usual screed

When installing warm floors, it is necessary to avoid heat losses to lay heat and waterproofing material before the fill of the concrete base.

Fiber for a tie of the heated floor is used in the same proportions as when the device is a conventional screed.

In addition to reinforcing additives, plasticizers need to be added, which contribute to the preparation of an elastic screed resistant to high temperatures.

Fiber does not waste concrete mix

The advantages of using fibrovolock when installing a warm floor:

- low cost and ease of transportation;

- resistance to moisture and other aggressive substances;

- Fiber fiber protects concrete from the effects of external negative factors and from occurring inside physicochemical processes;

- increasing resistance to shock and vibration loads;

- High resistance to minus temperatures and fire exposure.

Adding fiber to concrete solution helps to get high-quality, durable floor base without significant financial and labor costs.