Recently, buildings with polycarbonate are becoming increasingly popular. The material is inexpensive, aesthetically attractive, has a high plasticity, which allows them nonlinear surfaces. In the cottages or near the house there are increasingly arbors from polycarbonate. It is used for the roof and / or for the design of the walls, some - for glazing. There are as successful experiments and not very. We will tell that you need to consider that your building belongs to the category of "successful".

On the roof of milk plastic, "glazing" - from transparent

Experience use

If you ask for reviews about gazebos from polycarbonate, there is a very strange picture: some are satisfied, others - no. Moreover, some and others are categorical, opinions express not just so on the basis of their own experience. Two contradictions are drawn from these reviews:

- Under the polycarbonate is hot even in an open gazebo. However, not all. Someone is there even at noon the shadow "like under the trees".

- The roof broke the roof, and through. Someone and hail, and even launched by the "good" passersby stones withstands.

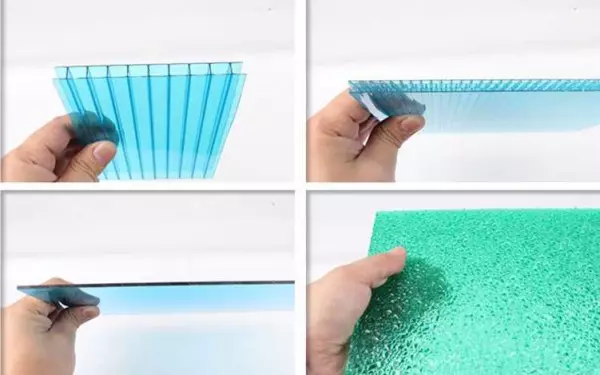

Polycarbonate is monolithic and cellular

If you understand everything, everything is explained. Polycarbonate are two types: cellular (cellular) or monolithic (cast). And that and the other can be used in individual construction. Monolithic is the material that was previously called the plexiglass. If it is fat enough, its strength is very high: glazing in some banks are made from monolithic polycarbonate. It is true, covered with a special protective film - so as not to scratch. If there is such a polycarbonate on the roof of the country gazebo, then the stones it will endure. But. It costs two or three times more expensive than cellular.

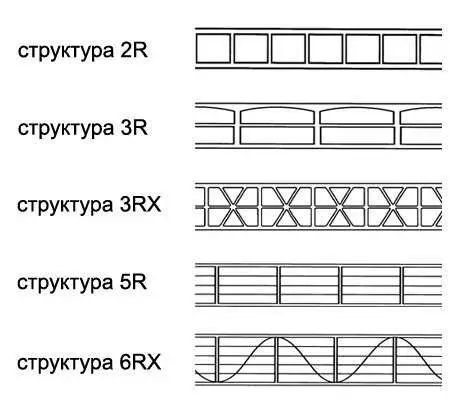

Cellular or cellular polycarbonate, as it is clear from the name, consists of cells that are similar to the cells. Hence the name. It is formed by several thin sheets that are connected by jumpers. Layers can be from two to six, and cells can be of different shapes. Some of the structures are shown in the photo below. Looking at this drawing it is easy to explain the contradiction described above, even if all the writing reviews used cellular polycarbonate.

The cheapest material has two sheets connected by vertical jumpers. Here he is fragile and brittle. It can be easily survived even with his fingers. Especially if the cell is large. The harder the structure, the stronger the material. How to find out what about you? Look at his transverse cut. There is visible geometry of cells. This is to the question of the strength and fragility of polycarbonate.

Article on the topic: How to assemble a log house for a bath?

The structure of cellular polycarbonate

Now that someone under the polycarbonate is hot, and someone does not. There are two factors that affect it. The first is regional. In some regions, the sun is not even in the middle of summer, but heats, and not very much. And even if the polycarbonate is selected, which is used in greenhouses - transmitting 80-90% of solar rays - people do not frighten, but pleases: it's nice to warm up.

The second factor - the type of material is incorrectly selected. As already mentioned, there is a polycarbonate that passes the sun's rays almost completely. It is used for greenhouses. There is one that skips about 30% of the world. Here it is necessary to put it on the roofs of the arbors or use for canopies. That's not all. The heat-insulating characteristics also affect the structure, and the thickness of the material: the more layers, the better the heat-insulating properties. In the case of a gazebo - under thick polycarbonate (8 mm) in the gazebo, even in the southern regions, Nezarko. The situation, in general, is familiar: cheap materials have a low price is not just like that. So do not save: it will be hot, and I also beat Grad.

What are gone from polycarbonate

In form - any. A very cool bend is difficult to make it difficult - the minimum radius of the six-time thickness of the sheet, but when building the arbors is not needed. All other forms can be sewn.

If we talk about cellular polycarbonate, then it is mounted on some framework. He lacks his own bearing ability. Monolithic with sufficient thickness - from 8 mm - can be mounted without any supports. But it is very rarely used, but it will be more about him.

Polycarbonate is attached to any arbors, but most often - on metal. Especially beautiful it looks with forged. The roof from another material "interns" structure, and translucent plastic looks weightless and does not attract attention, only emphasizing the beauty of patterns. Several photos of polycarbonate arbors are collected in the photo gallery, which is located below (leaf by the arrows or clicking on the icons, you can enlarge in full screen).

Very attractive came a gazebo from a bar, painted dark and milk polycarbonate. The roof in this embodiment is made of soft tiles

This is a closed gazebo from the metal glazed

These are two in one: open from closed arbors

Metal, tinted with orange polycarbonate - even on a cloudy day in the gazebo will be "sunny". This is an excellent option for regions where the sun is a rare guest.

Tree and polycarbonate - a couple who occurs infrequently

Article on the topic: Rolled curtains in Children: Tips for choosing

Blue looks great, but people in people sitting in such a gazebo of a strange color ...

High patched poles, decorative arches. The construction turned out to be weightless

Stone, wood, polycarbonate - a combination of beautiful and stylish

Due to the flexibility of the material to create and rounded shapes

Gazebo with forged elements

The dome roof of polycarbonate is not standard. Unusual turned out to be gazebo

Excellent version of the wooden arbor with the roof of cellular polycarbonate

Unusual shape of the dome over the extensive platform

Open gazebo in the meadow

Very interesting option: Design repeats the shape of the house

Cuts from a single-sided roof are infrequent

About the views and features of brick and stone arbors are written here.

FEATURES OF MONTAGE

During any construction, there is always a struggle: on the one hand, I want to save, on the other - to be beautiful, high quality and reliable. In the case of polycarbonate, it is better not to save. First, the quality is highly dependent on the manufacturer, and in the second even buying a thin sheet save in the end you are a bit. After all, the shade of the crate depends on the angle of the skate and thickness of the polycarbonate: the less thickness, the more often the crate is required. Well, a number of reasons why do not do it, we discussed above.

Each manufacturer has a similar table. But this is already visible that the thinner is the sheet, the more often the crate must be done

What could be the basis for polycarbonate? Any material: wood, plastic, metal. If the polycarbonate is mounted on the tree, it should be processed by antiseptics that will not give to multiply fungi and bacteria. This is due to the fact that condensate is formed between plastic and wood. Increased humidity and creates conditions for the development of fungi.

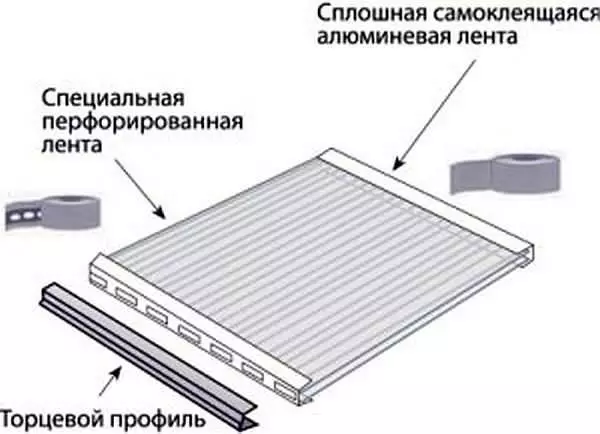

Slabs need to close

When laying on metal, another problem may occur. Under the sun, it is very heated, plastic is heated in small zones. This phenomenon leads to the fact that it sweeps over the metal frame. To avoid local overheating on the metal, a thin layer of heat insulating material is pasted. If you buy polycarbonate from a well-known manufacturer, self-adhesive thermal insulating tapes are in the set. If the material "observer", you can use any dense and flexible material with the corresponding characteristics. Rubber and cork comes to mind first, but a strip of felt can be approached, thin foamed polyethylene, etc. It will take it on the sealant.

If the base is plastic pipes, no problems arise: materials are similar characteristics, coexist without problems.

The process of manufacturing a canopy for a polycarbonate machine is described here.

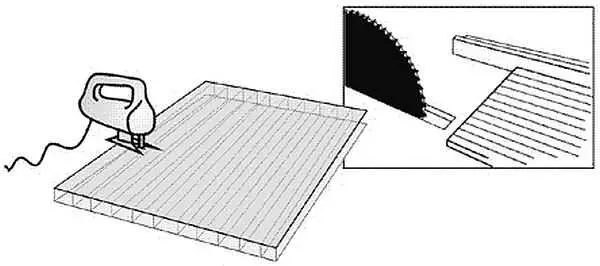

What and how to cut

Cutting polycarbonate sheets by any tool to be operated with wood. This is a hand saw, an electrolovka, a bollard with a wood disk.

Article on the topic: Machine production machine for drywall: making frame elements

You can cut both along and across the honeycomb. The ends of the transverse cuts must be sealing. When buying branded materials, you will be offered sealing (glued to the upper cut) and perforated tape (it closes the section at the bottom, and perforation - to remove water vapor or condensate drops), which are glued to the cut. If you do not have such tapes, you can smell with transparent sealant, but so that there is no cracks.

Cut sheets with an electric bike or grinder

Why don't they be left open? First, dust falls in them, rubbish that over time makes the roof or walls with untidy and almost opaque. Secondly, when air intake, condensate is formed on the walls, and microscopic green algae is perfectly multiplied in it. And the polycarbonate becomes a strange color, and the look at the same time ... ugly.

After the sheet was cut, honeycombs need to be cleared of dust from them. It is best to do this with the help of a vacuum cleaner. Then close the honeycomb.

About how to build arbors from wood read here.

How to kp

When installing it is important to remember that polycarbonate for the roof on one side has a protective coating from ultraviolet. It cuts off the harmful spectrum. On this side, manufacturers glue a film with logos. When mounting the roof or walls, this film should be top. It is removed immediately after the end of the installation. Not "before" - so as not to scratch, and not in a week - the film will stick to the light, and it will be problematic to remove it.

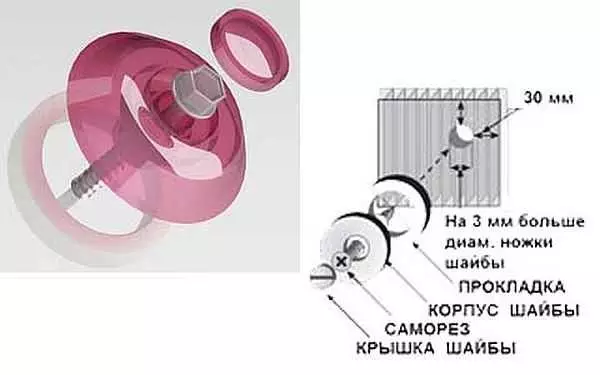

For fasteners, special thermoshairs are used with plugs or bolts with a mandatory metal and rubber washer. Under each fastener, the hole is pre-drilled. Its diameter should be 3-4 mm larger than the fastener diameter. If thermoshaba is used, it has a rather thick leg. Therefore, the diameter of the opening should also be greater.

Thermosicles provide reliable polycarbonate attachment

When installing fasteners, the main thing is not to drag. Plastic should not be fed. When using the thermoshair, its leg is served by the limiter, and with self-drawing it will have to control the effort.

For the joint, plates use special profiles. They allow you to compensate for the thermal extension (approximately 3 mm per meter of length) and simultaneously guarantee reliable fixation. Details about profiles and all intact intact is told in the video.

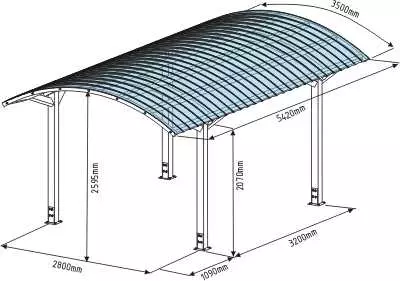

Blueprints

Any of wooden or metal arbors can be covered with polycarbonate. Therefore, individual projects practically does not happen. This is only a private finish case. Several drawings that can be made from both a tree and from metal we will lay out in the photo gallery below: Purl, choose.

Rectangular Arbor with Four Sheet Roof