The hoses are very common and are often used in private sectors, especially in the country areas and gardens in summer periods (organization of water supply, hose irrigation of various vegetation, etc.). They are much easier and more convenient than with pipes. If desired, the hose can be trimmed, as well as increasing, it is easy to transfer them, the hose alignment does not require almost no skills and expensive devices. There are several solutions, in accordance with which high-quality hose alignment can be performed: folk remedies, tested by time, and plastic connectors recently appeared. Modern plastic solutions (tees, adapters, crossmen and other connectors) are offered by a variety of manufacturers, solutions are available literally for any occasion. Such devices allow you to perform a fast and high-quality hose connection, they can be used both within the site and in the garden. They are perfectly suitable for connecting products of any type for frequent switching between water points.

Scheme of the conjugation of rubber water supply: 1 - valve, 2 - adapter, 3 - tee, 4 - clamp, 5 - hose.

Ways to connect hoses with their own hands

If you do not want to buy modern plastic devices for connecting products, you can use one of the proven folk methods: through an inexpensive adapter, through a pipe segment and through the fitting (if the hose is connected to the pipe).

To date, fittings for hoses are available for any pipe and for any hose, and they are cheap enough.

For polypropylene pipes, you can use similar solutions with external thread by screwing into the fitting. The only moment to which you need to pay attention is the thickness and length of the fitting. You can grab the hose with the help of a special clamp, you can use the wire cleaner. In terms of the quality of the connection, the difference is absolutely no, but the cost is reduced several times, if compared with factory plastic connectors.

The usual thing when many different hoses are lying on the garden or in the garden. Product segments can be connected using a piece of suitable size pipe and used in the farm. It is done very simply: the hoses are put on a length of about 10 cm on a length of 2 sides and grabbed, as already mentioned earlier, with wire or clamps.

Article on the topic: Steam heating batteries: types and appointments

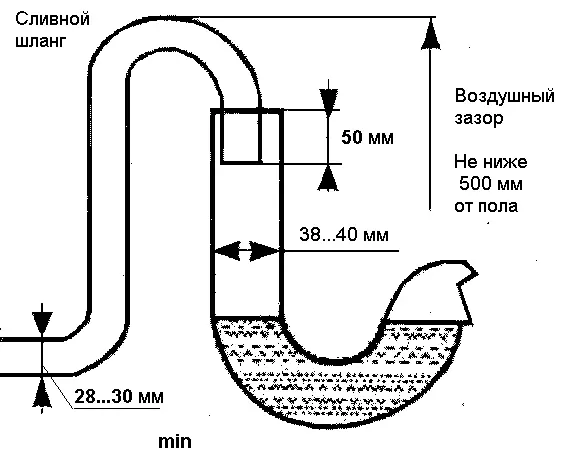

Connection diagram of drain hose.

The connector adapter, as well as the pipe mentioned in the previous example connects both pieces of the hose, only has special notches on the ends, which make the process of docking with a hose easier and more easily, if the diameters of the connections are not quite suitable for each other.

You can independently make the hose connector from the coupling and polypropylene segments. As a collection, such a home-made connector looks good enough and high quality hoses on ¾. In the same way, you can make a tee for connecting hoses. The nearest store analogue is a coupling (products are clamped using a cape nut and petals on both sides).

For high-quality and reliable hose connections, prepare the necessary tools and materials, namely:

- pipe cutting scissors;

- crafting table;

- couplings;

- adapters;

- nuts;

- clamps;

- wire;

- spanners.

High Pressure Hose Connection

Scheme connecting the hose to the filter.

The life of metalhouses depends mainly on the quality of the high pressure hose compound. In addition, it is very important to choose the right clutches, fittings and other design elements. All items must necessarily comply with the operating characteristics and technical parameters of the metal worker.

The modern market presents a very large range of products used to connect high pressure hoses with operated equipment and equipment. Suggestions are available from foreign and domestic manufacturers.

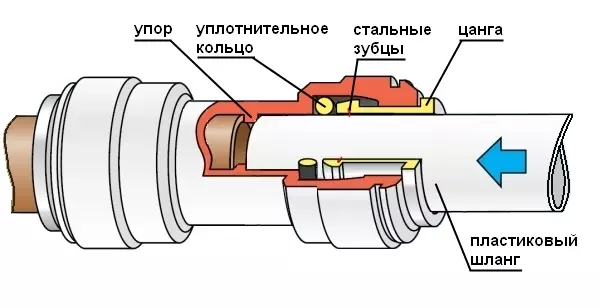

Basically, different compounds differ from each other by the types of fittings (size or type of thread, the seal method), as well as methods of compound. Today, the most common clamping type of the terminal connection is most common. This design is solid with a hose and is characterized by increased strength. You can separate a similar hose by sawing the clamping sleeve, which, in turn, eliminates the further use of fitting.

In accordance with the design features, 3 main types of connecting terminal connections are distinguished.

So, a compound of 2 elements is a sleeve and a separate fitting. When assembling the fitting is inserted into the hose, after which the clamping sleeve is put on. This type of compound is more often used in Russia and European Union countries. This is due primarily to the fact that for a variety of fittings, the same sleeve design can be used.

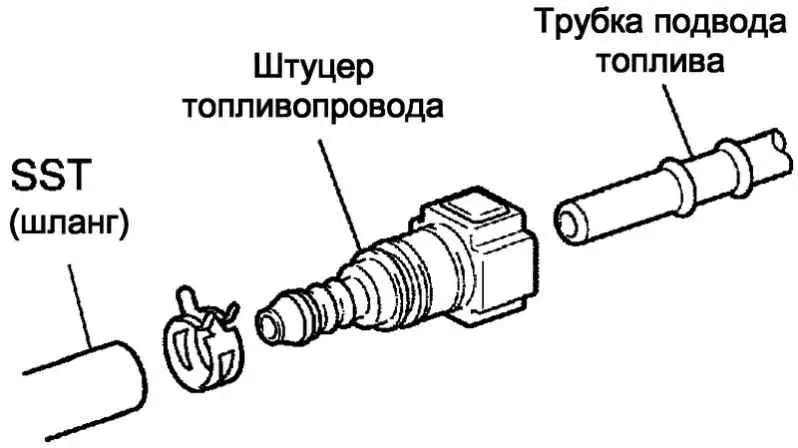

Scheme of the connection of the fitting with the fuel line.

Article on the topic: Select the mirror in the hallway: Decor tips and an increase in space (50 photos)

The integral connection type consists of one piece. In this design, the clamping sleeve and the fitting are a single integer. When using this option, the connection is significantly increasing warehouse costs, but the probability of allowing an error when choosing a clamping sleeve is noticeably reduced.

And the third type is a curly connection. It includes a clamping sleeve and a separate fitting equipped with carvings. When assembling the bushing hits the hose, after which the fitting simultaneously screws into the hose and sleeve. At the same time, the connection type clamping fittings and bushings can be used multiple times, but at the same time this type of connection is somewhat more expensive than others.

Instructions for connecting hoses do it yourself

To connect products, you will need a certain set of tools, which was mentioned earlier. In most cases, you can do without workbenk, however, it is much more convenient and faster with it. For plastic nuts, the gas key and fum-tape will need. For polypropylene requires special pipe cutting scissors.

The hose is connected to the water source. It may be, for example, a collector. The hose ¾ is attached to the clamp right on the cut pipe, welded to the collector. Excessive valve can not be put in order not to increase the weight of the structure. The second end of the hose can be carried out to a twist of the steel pipe of about 20 m (can be changed to propylene, but taking into account the protection of pipes from rodents, it turns out quite considerable). On the end of the pipe is put on a branch-splitter with 2 mini-valves. It is connected to it from one side through the connector ¾ and adapter. The second valve is the backup.

If the pipe at the other end does not have a thread, you can wear a special adapter under ½ and a context with a rubber end. With the rest of the discharges, the switching of hoses is carried out according to a similar principle.

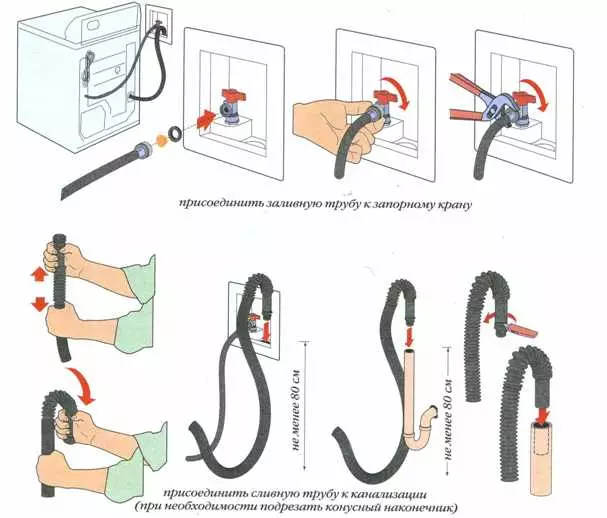

Connection diagram of drain hose washing machine.

Now you can connect any hose with the connector and perform a wiring along the site through the tees, if there is a need for a multi-rigor watering system. The huge advantage of the connector in front of the holomatic connections is that the possibility of unhindered connecting and disconnecting the connections and replace the tips appears.

Intermediate hoses are mounted between polyvalny tips (splashes, pistols, etc.) and connector. When buying ready-made factory sets, it is necessary to pay attention to the cross section of which hose the attached connectors are calculated.

Article on the topic: Wet plaster - a modern way to finish the walls

The order of connecting household hoses

Often there is a need to connect not only garden hoses, but also others, such as the washing machine hoses. Periodically, many owners of washing machines have to deal with the problem of damage to the drain hose or its insufficient length. In this case, you can quickly increase the old hose with the same (or approximately the same) new hose.

It is possible to make a reliable and high-quality compound by fixing rubber tips using clamping car vehicles through a solid tube (you can purchase a special connector). The most optimal size of the clamps is not more than 27 mm. If you do not have a special connector, you can take a segment of a durable plastic thin-walled pipe with an outer diameter of about 20 mm. In such cases, you can recommend to use the screed-fixation for clamps.

In the event that the tip of the complete washing machine is plastic, and not rubber, then you must first start it inside its trim tube suitable on the outer diameter. Then it is put on top of a rubber tip. The resulting design is fixed using 1 auto-flying. If you wish, you can try to completely replace the old drain hose of the washing machine longer, but there is no particular sense in this, because The new hose can be simply not to approach the design, so it is better not to risk.

The stores sell hoses of various lengths, but 5-meter and longer are quite rare. However, the extension of the hose of the washing machine even 5 m is already considered unacceptable, because This design will be unsafe.

Extension is performed in different ways and depends on the required length of the hose. So, if you need to lengthen the hose to 1.5-2 m, then this can be done with the standard drain hose for washing machines; up to 3-3.5 m - with a metal-plastic pipe with a diameter of 20 mm (if necessary, the pipe can be dried into the floor or sew in the wall). For heating and pressure water supply such a solution is unacceptable. If the distance is more than 3.5 m, the washing machine must be transferred closer to the siphon (or move the siphon to the machine).

When the washing machine washing, the drain and fuzzy hoses should not be in contact with sharp objects or rough surface. Otherwise, the hoses can scratch through due to the movements arising from pressure drops.