In small-sized apartments, tenants face an insufficient place for the location of comfortable furniture for leisure and storage of bed linen. In a limited room room, it is difficult to accommodate all the necessary furniture: tables, chairs, couch, bonders, beds. A good solution to saving the useful area and the formation of an individual interior becomes independent manufacture of a bed with a lifting mechanism, which combines 2 furniture items - a bed and an end for bed linen.

A bed with a lifting mechanism is an excellent solution for a small room.

A homemade comfortable model is not inferior in quality and design, the subject of furniture made in the production conditions, and sometimes exceeds it in operational characteristics. For those who have some skills in the manufacture of furniture, fulfill a modern functional bed with their own hands will not be much difficulty. Performing is conducted in several stages: A sketch is created, the frame is made, a box is formed, the framework of which the frame is placed, the lift is placed, a pre-purchased orthopedic mattress is placed.

Advantages and disadvantages of homemade furniture

By creating a bed with your own hands, the author forms the interior of his own apartment that meets individual preferences. Bed with a lifting unit, made independently, has advantages and disadvantages.

The advantages of the model with the lifting mechanism are:

- the use of environmentally friendly materials;

- The presence of a wide box for bed linen;

- Equipping a convenient mechanism that allows you to easily raise the unit;

- reliability;

- practicality;

- The possibility of making models of the desired design, designs and sizes, ideally corresponding to the dimensions of the designated area for installing the bed;

- low material costs;

- exclusivity;

- simplicity of design;

- Functionality: Bed with a lifting mechanism can be made embedded;

- Used orthopedic mattresses allow us to maintain a torso during sleep;

- ergonomics;

- the ability to quickly and conveniently assemble bed;

- Degree of wear and linen degree.

Article on the topic: Bathroom in a wooden house do it yourself

The disadvantages include:

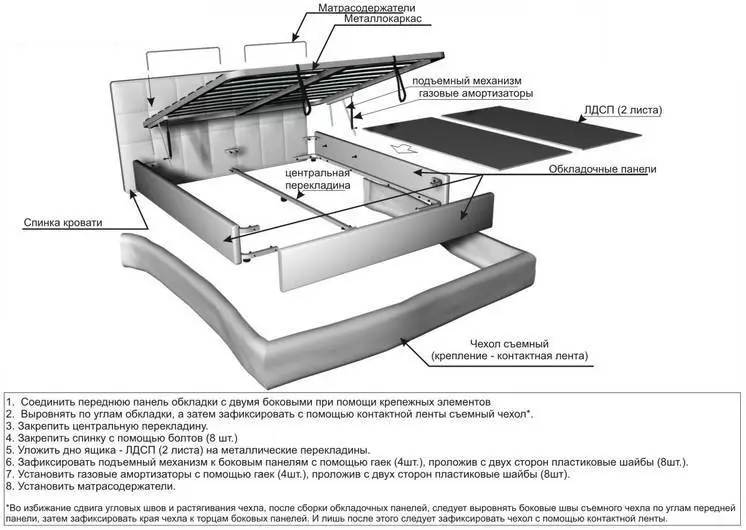

Bed design circuit with lifting mechanism.

- Unavailability of a niche under the mattress during a person's rest on the bed;

- the duration of manufacture;

- In case of insufficient experiment, it does not avoid unforeseen costs associated with the purchase of additional material due to damage the main;

- In the manufacture of a double model, spring mechanisms will not withstand large loads, gas must be applied;

- the possibility of only vertical lifting of a double model;

- Under each type and mass of the orthopedic mattress, a certain type of lifting mechanisms is selected.

Required materials and tools, creating sketch and frame

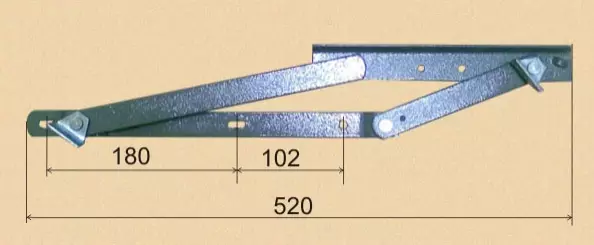

Scheme of the size of the lifting mechanism.

To perform a model with a lifting mechanism, instruments and materials are needed:

- screwdriver;

- screwdriver cross;

- self-tapping screw;

- bolts;

- welding machine;

- electrolovik;

- Bulgarian;

- stapler;

- roulette;

- plane;

- drill;

- Chipboard;

- board;

- Bar;

- Lifting mechanism;

- fabric for upholstery;

- foam;

- metal profile of square section 20x20 mm;

- PVA glue;

- orthopedic mattress.

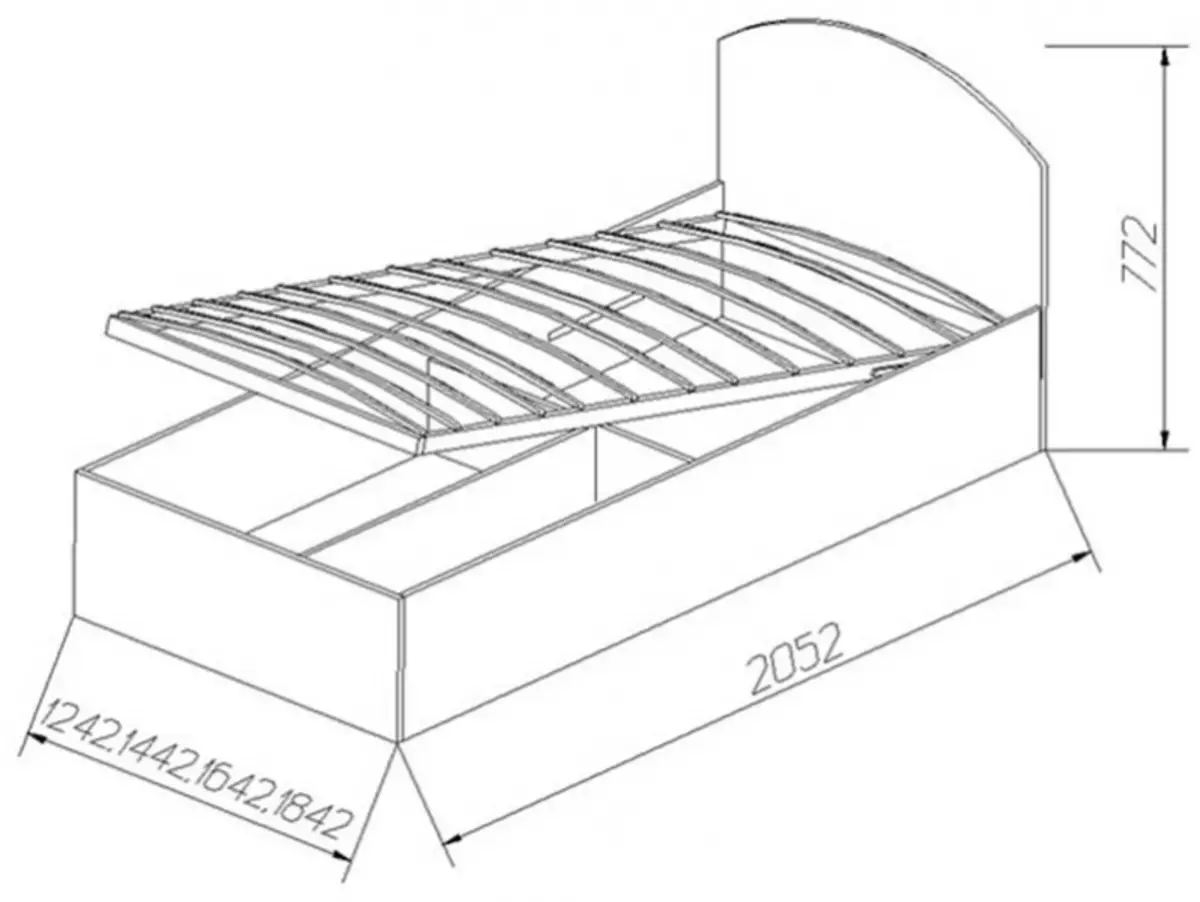

Bed frame circuit with lifting mechanism.

At first, the orthopedic mattress acquire, given the personal preferences of the owners. Then the sketch of the product due to the sizes of the mattress. The sketch displays the composition of the bed with side and end items. A sketch has a type of box of 4 boards and 4 transverse parts for the formation of the bottom under the frame. When creating a sketch, the sizes of the mattress are taken into account. The mattress for an adult has a length of 180-200 cm, a width of 80-180 cm. The manufactured steel frame will increase the operational characteristics of the model, which is especially important in the production of a double sample with a large full of owners.

The frame is performed from the steel profile of the square section, additionally set several transverse racks in longitudinal and transverse framework elements in increasing from 600 to 900 mm. Billets are cut with a grinder, connected by the welding machine. Vertical racks can be positioned at some points of attachment of parts of the lifting mechanism. Rama-frame is equipped with a handle ring from leatherette.

Formation of a wooden box, installation of a lift, upholstery

This stage of work includes the selection and acquisition of a suitable finished lift for the product. It can be placed in the headboard, the function of the mechanism includes lifting the mattress from the side of the foot end. At single and half-and-half models, the lift can be placed in the sidebar.

Article on the topic: Crafts from foam for giving: We make figures from foam with your own hands (30 photos)

Now we create a wooden box, which is a kind of frame for a frame. Working on the opening of the side walls and the bottom of the model according to the required dimensions are underway, wood, chipboard is used, an electrolovka is used. The ends are connected by corners using self-tapping screws, or a connection is performed in a spike on PVA glue, and it is necessary to check the diagonal. The box is ready. The framework is placed in it. Now the lifting mechanism is mounted, its function is checked, it is adjusted if necessary.

The finishing of the outer surface of the side walls of the model is the final in the manufacturing process. Used upholstery fabric, leather, dermatin. The upholstery is performed by the furniture stapler. The gasket of the foam rubber between wood and upholstery creates airiness, the required volume. At the end, placed an orthopedic mattress.

A unique bed equipped with a block lifting device contributes to a good rest, becomes a functional piece of furniture, participates in the formation of an individual interior style.