Photo

The easiest way to make a sofa, which consists of several transverse and guide bars.

If you feel sorry to give a fabulous money for the finished sofa in the store, then try to make it with your own hands.

This design is simply quite simple, and it will take only a minimum set of tools and materials.

How to make a simple sofa properly?

It will take to develop a drawing, make an accurate calculation of the number of necessary materials, purchase tools and build construction. You will need the following tools:

Basic tools for assembling the sofa with their own hands.

- Corolnic;

- electric drill;

- a hammer;

- electric jigsaw;

- Building stapler.

From materials it will be necessary to purchase:

- Metal corners;

- Bar;

- Morner or colored glaze;

- foam;

- lightning and velcro;

- Durable cord.

For the urban apartment, the sofa of this design will look rude, but it is ideal for a country house or cottage. There are several reasons why the sofa should be done:

- It will be possible to significantly reduce cash flow. Such a design will cost many times cheaper than the product acquired in the furniture store. However, it should be remembered that the savings should not be to the detriment of quality.

- The possibility of obtaining high-quality design.

- The ability to choose your favorite fitness.

- You can get the design of the required size.

- In the future, you can drag the sofa, reducing cash costs.

Wood for the manufacture of the sofa is recommended to choose without bitch and rot. During the final finishes, exceptionally high-quality upholstery materials should be used.

This design consists of a back, front panel, seats and armrests. The base will be fixed on the finished frame.

Sequence of actions for the production of a sofa

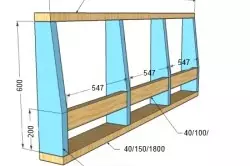

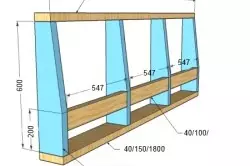

Drawing of the backrest sofa with sizes.

First of all, you need to prepare bars of suitable sizes. It is not recommended to produce a design of pine, as such wood is not able to withstand deformations and it must be additionally handled.

After that, you need to make accurate measurements. It is necessary to put mark on the elements and make grooves, then drill holes for the pile on the frame so that it is possible to install fastening screws into the lower horizontal frame of the frame, excluding the cracking of the stopper.

Article on the topic: Repair of floors in Khrushchev: how to do, advice experts

In the process of preparing materials, you need to pay attention to the drawing of a tree. Compounds need to be done so that the annual rings are located by convex sides each other.

After the assembly, all items must be thoroughly stabilized. After that, the base is processed with colored icing or verses.

It is worth noting that the size of the finished design will be set by the parameters of the sofa base.

In order to make support legs, a durable breed timing should be used in 7x7 cm cross-section and a height of less than 10 cm. To ensure a reliable connection, it is necessary to secure the timber on metal corners.

The back can be made with a slope. The skeleton should consist of 2 horizontal and 4 vertical boards. The height of the back should be chosen based on the growth of the user and personal preferences. On the back of the skeleton, Phaneur must be applied completely. From the side to which the back is based on, Phaneur needs to be imposed solely on the open part. The bottom can be closed by the seat. Examine the backup drawing with all sizes can be seen.

Making soft seats

Soft seats manufacturing pattern for sofa.

Seats can be made of foam rubber with a density of more than 35 kg / m³. It should be laid in several layers. The base is covered with a protective web, which will allow minimizing friction between the decorative coating and the sofa frame. Thus it will be possible to exclude the formation of folds.

The coating for the backrest is made of a foam rubber of a smaller thickness, so the reference load is much smaller than the load on the base of the sofa. In order to sew a decorative coating, you should use a durable cord. Along the rear edges of the lower part of the design, lightning or velcro should be located. The upper part of the seats is fixed by velcro.

How to make a digital sofa with your own hands?

There are structures that can be used as not only sofa, but also beds. These designs include roll-out sofas.

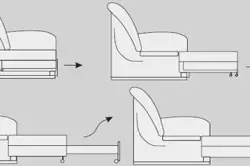

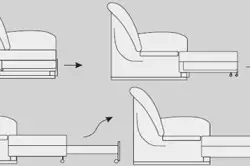

Scheme of a roll-out sofa.

One of the most common types of sofas is exactly the design. In this case, the sleeping place is extended from the bottom of the structure. To extend such an item, you will need to pull for a special handle or loop. Pillows are stacked on the rolling part of the sofa. Such pillows in the folded form can be used as back. There is another type of disconnecting design: the back in it consists not from several pillows, but from a solid soft base. When sofa is unfolded, the back and seats are installed on the extended part.

Article on the topic: Sharpen chainsaw chains do it yourself. Sharpening tool

The advantages of the disconnected sofa include the following properties:

- The retractable part of the design has large sizes, because it can be placed even a few people.

- Small design sizes in folded position.

The disadvantage is that in the decomposed position, the construction takes a large number of space. Therefore, it is not recommended to install it in small rooms.

Make a digital sofa with your own hands is not difficult if there are minimal skills. The following items will be needed:

- a small amount of 5 cm thick and 10 cm high or more;

- Fiberboard;

- Bar;

- backs;

- seats;

- Material for cutting frame;

- dense foam;

- varnish;

- door hinges.

For construction construction, pine panels will be used that will need to additionally process. After all the necessary tools and materials are prepared, you can start work.

Procedure for the manufacture of a roll-out sofa

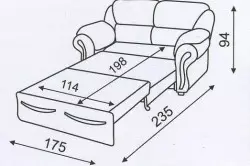

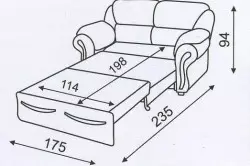

In this case, the design with the size of a bed of 1140x1980 mm will be manufactured. Consider the sofa drawing.

For the manufacture of the design, you must perform the following actions:

DIAGRIBUT DISTRIBUTION.

- The back will be made from the furniture shield, on which the above edge markup is carried out using the pattern.

- A diamond gap and the upper edge of the back are cut down on the markup. This can be done using the use of an electric bike. Before making a diamond-shaped opening, drill in the opening shield under the tool saw. Also need to do 2 holes near non-stained corners of the figure. In sharp corners, you will not need to deploy the saw tool. After being taken from the edges, you need to remove traces of cuts.

- After the pattern is made of all other elements from the shield, they must be well stabbed. In the process of the product of this operation, it is necessary to reliably fix each element that needs processing. To do this, the raw surface must be fixed on the vertical board.

- With the help of the mill, you will need to process the edges of all billets, for which the corresponding profile mill should be used. If there is a desire, ready-made components can be additionally toned. The color of impregnation is selected, based on the design of the room in which the design is installed. At the end, it is necessary to cover the wear-resistant colorless varnish.

- After that, the reference rail should be fixed to the wall. The size of the roll-out sofa and the consolidation height must be determined based on the convenience of using the design. After determining the total height, you must select the height of the side supports of the folded seats. The first thing the rack is fixed in the middle so that in the future it was possible to put it horizontally.

- Rake is mounted in terms of level. This element needs to slowly rotate around the fastening screw. After that, the rail is fixed at the edges.

- Another bar should be placed on the reference rail, the folded seats are fixed on the loop. After that, the timber is fixed by self-drawing to the bottom of the structure. All holes for self-tapping screws must be pre-done in the rail.

Article on the topic: Sizes of balcony plates

Work marking seats and backing installation

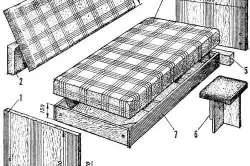

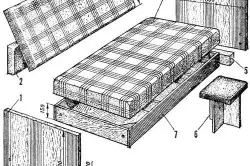

Collection scheme of folding sofa: 1 - sidewall, 2 - additional pillow, 3 - pillow - back, 4 - retractable mattress, 5 - support timber, 6 - Stool Stool, 7 - Base-base.

After that, the placement of the placement of the loops for the scene elements is performed. On the markup, it is necessary to make holes in the wall under the dowel, after which the loops fasten with screws. After the loops are located in their places, they need to install side supports of the seats.

At the next step, the back of the sofa is made. It can be fixed using self-adhesive tape, since the back will not carry any power load. As a result, there will be no traces from the fastener elements from the outside of the design. The back can be trimmed by a little thickness, which will be closed in a case. Thus, it is possible to give the design an additional aesthetic appearance and make it more comfortable.

Picky sofa is an excellent combination of an ordinary sofa for a rest and practical space for sleep. Similar structures in most cases are installed in small-sized apartments, since with their help you can combine the living room and the bedroom.

If you follow the instructions and comply with the sequence of actions, you can make a digital sofa with your own hands for everyday use.