Arbors from metal like someone, there is no one. Do not like mostly those who prefer wood. But the one who came across the departure of the tree, which all year round is on the street, knows how much time, forces and means takes away the maintenance of its normal appearance. From this point of view, the metal is better: carefully processed and painted it does not rust for years, it does not bother it, it does not die and does not swell, does not rot, does not affect fungi and is not covered with mold. The worst thing that may happen to him - he is delayed. But from this "illness" there are proven medications: sandpaper, rust converter and paint. Therefore, the arbor from the metal is collected with their own hands. They are also good because they can withstand significant loads and can be combined with any finishing materials for both walls and roofs.

Types and methods of assembly

In addition to different shapes - rectangular, hexagonal, eight-marched, round - metal frame can be installed in two different ways:

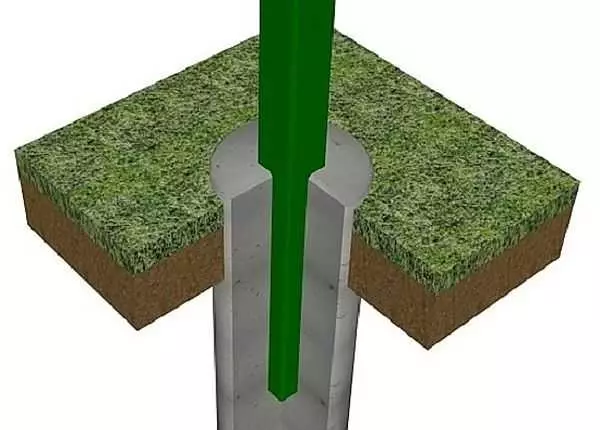

- Vertical frame tubes are concreted into the ground. These racks are then attached to all the rest of the design. With this method, the presence of a foundation on it is envisaged. In principle, by making at some distance from the ground, the bottom strapping, the floor can be to be token, but most often with this method of manufacturing the iron gazebo, the platform is concreted or paving paving slabs.

Under the metal racks, the wells are dried, the pipe is inserted, the empty place falls asleep with rubble. The pipe is exhibited smoothly, rubble trambets, then poured with liquid concrete

- First make fine-breeded columnar or ribbon foundation, sometimes poured the monolithic slab, lay the platform with tiles, etc. The framework is constructed separately and fixed after being ready at least lower strapping and racks. If the foundation is columnar or tape, the pipe is put on it and connects to the place: only a crane can be raised the finished design.

This is a gazebo from the profile pipe on the columns

What is the better way? Depending on which side to look. If the fastening is better - the first: the racks are closed. Also, this option is more economical: there is no lower strapping and no costs for the manufacture of the foundation. But such a design, if she is without sex, is only a summer gazebo. For winter, closed, you will need the floor.

The gazebo on the foundation is better from the point of view that it originally implies the presence of sex. In addition, the exaltation, even if it is small, protects against splashes and dirt from entering inside.

Methods of assembly

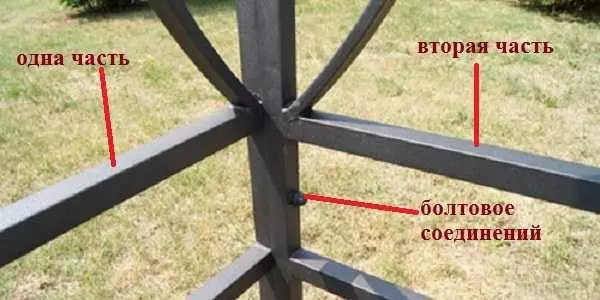

Traditionally, metal is combined with welding. It is fast and reliable. But in the case of a cottage summer gazebo, a collapsible design may need. Indeed, on an unguarded country, to leave for the winter a large amount of iron is very unsafe. In the sense that it can easily steal. In this case, the modules are welded, which then are connected to bolts among themselves. As a rule, such collapsible arbors made of metal are a frame to which the awning is mounted, or another similar quickly mounted or dismantled fence and the same light roof.

For the metallic gazebo, framework frames for each side, then collect them with bolts

The frame in collapsible arbors is broken down. If it is quadrangular, boil four separate contours with all the necessary jumpers. In hexagons - their six, etc.

What metals do

Most often, the arbor from the metal is made from the profile pipe: it is easier to work with it. The wall thickness should be at least 2 mm. Thickering for nothing: they sell it mainly on kilograms, so that with the same outer sizes with a thicker wall are decently more expensive.If you use round pipes, the wall thickness remains the same. It is more complicated to cook them, but if the experience is already there, why not: they cost less than profile. You can use a metal corner. But its thickness must already be 2.5-3 mm: less rigidity. Under the trim, such a gazebo also looked good.

How to cook inverter welding machine here.

Weekly went about steel. But profile pipes and corners are made of aluminum. The design will be much easier that in the case of a collapsible gazebo, it can be very useful. But there is such a pipe several times more expensive.

About how to attach a veranda to the house read here.

How to make a gazebo from the profile pipe: Step by step instructions with photos

Before cooking, you need to purchase a metal. For racks, the profile tube is suitable:

- 50 * 50 mm, if the roofing material is lightweight - a professional sheet, metal tile, bituminous tile or slate;

- 75 * 75 mm with roofing from slate or tiles.

For jumpers take a thinner profile. Maximum, 50 * 50 mm, at a minimum - 20 * 30 mm. Its dimensions are highly dependent on how big the design is. Under powerful construction sites take more sections, under smaller, understandable, smaller. It is worthwhile to take into account the also the weight of the finishing material, which the framework from the sides will be chopped (if it).

Homemade gazebo from the profile square pipe, size 3 * 3 meters

For the manufacture of a square gazebos 3-3 meters (photo above), the height of 2.2 m stands, the following materials were used:

- Pipe for the strapping50 * 50 * 2 mm - 12 meters;

- For jumpers profile pipe:

- 40 * 40 * 2 mm - 14 meters;

- 20 * 20 * 2 mm - 6 meters;

- 40 * 20 * 2 - 30 meters;

- Metal strip 20 * 4 mm 2 m long.

Post-markup and installation

If the site was planted, the grass grows on it, the fertile layer must be removed. Otherwise, under the floor, plant residues will rot. During construction, it was not done and the smells of two years in a row were mildly "not very".

The resulting pit, if you have a good water from the site, fall asleep with sand or "native" soil, but without a vegetable layer and non-frozen. If the soil is clay, be sure to fall asleep the same clay.

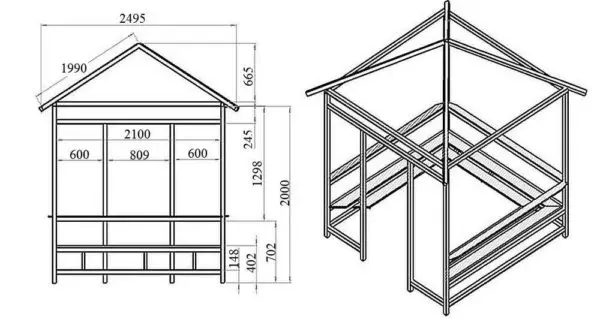

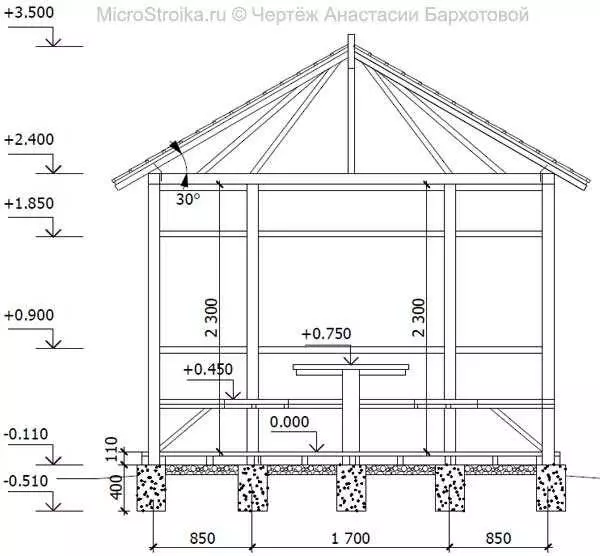

If you already need a drawing, here is a scheme on which a square gazebo with a four-piece roof. Sizes 2.4 * 2.4 m, height to the upper strapping - 2 m (can increase if necessary)

If you are going to install pipes immediately into the ground, they are thoroughly prim. Then, the pits, a depth of about 70-90 cm. Diameter depends on the otbura that you have. A pipe is inserted into the finished pit, falling asleep with a large fraction of rubble or construction garbage, it is exhibited precisely vertically, crushed stone tram. The exhibited stand is poured by concrete solution. If portland cement m 400 is used, sand can be taken 3-4 parts, the concrete must be liquid to spilled deeply.

The second option is someone holding a rack smoothly, or you found a way to fix it. Then pour the pit is required by concrete with an aggregate from the rubble of the middle fraction. The proportions may be such: on 1 part of cement, 2 pieces of sand, 1.5 - rubble. About the brands of concrete, read here.

What does such a rack look like

Another point: the verticality of the installation of the rack is not checked by a construction level, but a plumb. The level is too big error. And the plumb is practically unable. Magnetic plumbers are very comfortable for working with the metal: they have a magnet in the case. Just put the housing in the right place, and the plumbing holds himself.

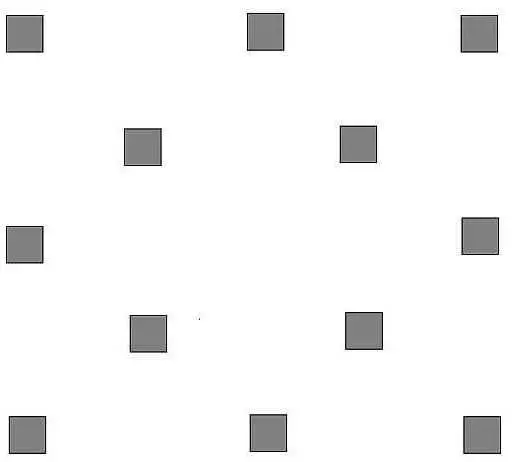

If you prefer to lift the gazebo, it can be put, for example on the foundation blocks. Since a whole block for a gazebo is a luxury, then blocks 200 * 200 * 400 mm can be cut in half (with a diamond disk). The resulting cubes are located in Square: one in the corners, interrupted four more, and in the middle of a checkerboard, 4 more pieces. The scheme is obtained as in the picture below. The blocks in the middle are needed so that the pipe does not be bitten: three meters with a rib 50 mm without support sagging.

Scheme of the position of columns under the arbor 3 by 3 meters

So that concrete did not pull moisture, it was missed from all sides with bitumen mastic, because they are black on the photo. You can squeeze, someone has a resin, or put on top of the rubberoid in two layers. But Ruberoid will turn around in a couple of years, his quality today is nowhere worse.

All blocks are set to one level. To make it easier to set the angles, knock the pegs, stretch the thread, checking the diagonals, the blocks are displayed according to a given scheme. All their tops must be in the same plane. You can do this in several ways:

- stretch the shoelaces, check and set them, and already ravized blocks on them;

- Use a long smooth rack (board) to which the construction level is put (tested and with a small error), and so exhibit all the blocks;

- Take advantage of the laser level, but in sunny weather it will not work with it - it is almost not visible (or is needed special, with such a function).

As you understand, wroks with blocking blocks can be avoided if fixing the pipes into the ground. True, the belt strapping will also need to do smoothly.

Low strand and racks

After the blocks are exhibited, the segments of square pipes are placed on them. In the manufacture of the lower strapping of the metal gazebo, a profile pipe is used 50 * 50 mm. If you wish, you can take more powerful, but the gazebo has been worth 5 years, though more than 10 people have not yet been going.

Pipes are placed, the horizontalization is checked again with a level. Boiled in the corners. Then from the pipe of a smaller section - 40 * 20 mm make two jumpers to which the floorboards will be relying (or plywood, if you want to use it).

Finished lower strapping

All pipes are crushed twice with primer, special attention was paid to welding places. Racks are made of 220 cm high: so that the roof is headloved. The racks turned out heavy (50 * 50 * 2 mm), and in order to fasten them more reliably, they were welded assembly drives from a metal strip 20 * 4 mm (see photo).

Method for fastening vertical racks by mounting bodies

The pillar is put exactly, its direction is checked (more convenient to magnetic), after which the bodies are clamping clamps. So boil is easier: the runoff is almost dead and the assistant is needed only for insurance. First, coperate the pipe around the perimeter, and then alternately removing the clamps also ships. They hold even with a height of 2.2 well.

Racks at the door from the profile pipe 50 * 50 mm in this gazebo end at the level of the railing. To increase the stability of the design, they are better to put the same height. But in this case, the owner decided that the construction was stable (at the expense of Ukusin) and decided to save a little.

About the basics of welding inverter welding machine here.

Railing and upper strapping

The height of the railing in the gazebo is 95 cm. But it is possible less, and more is not fundamentally. You can even without a railing. For example, under a solid glazing with polycarbonate. Or closing one or two walls with opaque finish (from neighbors and / or from the street).

The average strapping is railing - made of pipe 40-20 mm, the same section and upper strapping. To increase the rigidity between the first and second strapping, two vertical racks are welded (height 95 cm, cross section 40 * 20 cm). The whole design in the next photo.

Fully assembled cutting pipe frame for arbor

Roof

Next came a turn of the roof production. This iron gazebo will be a bituminous tile, because the rafter design is made of wood. For the frame, the bar 75 * 40 mm is taken, lining was used to the crate under the soft tile: so that the appearance of the bottom was also attractive (can be replaced with moisture-resistant plywood).

Squares of wood are clogged into the open ends of the racks so that this cork enters into a pipe at least 10 cm. From above, there are slices of 5-7 cm. Slingers are attached to these traffic jams. They can be trimmed almost under the root, leaving a bit so that if necessary, it was possible to cut them off an angle.

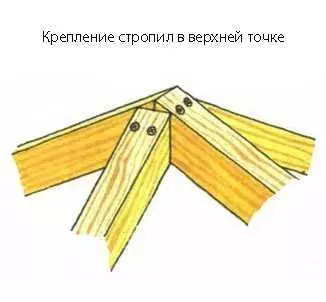

How to bore rafters at the top point

Cut rafters - 4 pcs 2.5 meters. All 4 pieces are connected at the top in one design. The height from the zero level to the top point is about a meter. First connect two. In order to be a bias feed them. Long nails are knocked down. On the left and on the left are the two remaining bar (ends also cut at a small angle). So that they keep tightly, the corners of the stainless steel are screwed.

Since it is inconvenient to handle rafters at the top, they immediately, even on the ground, are impregnated with an antiseptic and painted with a mourn with protective properties (they chose the color light to be more pleasant inside. It was treated at once all the boards and lining for the trim: rain and she could quickly sit.

Then the auxiliary board is stacked in the center, an auxiliary bar of about 85 cm is killed on it. It is in short, so that the rafting legs go a little over the perimeter of the strapping. So the roof will be larger, flowing from the roof the water will fly less.

The design of four rafters collected on Earth is watered on top of the arbor. Its top must rely on the bar. All this is centered. We check the verticality of the bar, but further measure the distances from the center of the rafter system before the place where each rafter foot resumes in the frame. If everything is more or less normal, pinch the ends of the rafted to the drive plugs. Then the backup and the board are removed, you can mount the crate.

How the rafter system was installed (covered from rain)

Under the scene, more additional drives were nailed (from the same bar 75 * 40 mm). How it is done - see the photo below.

To the board (below it turns out the length of more than 3 meters) did not bete, approximately the middle of the baked bays (film - from rain, even wood and processed)

The shapper under the soft tile was made of the lining. It is more expensive than the edged board, but her aesthetic appearance is better. After mounting the crate, the bitumen tile is stacked. It simply spreads and nailed into the mounting holes by cloves. Mounting begins bottom, moving up. It cuts on the spot with scissors, it's easy to work. On the sides, in the joints of the joint, it is nailed after 5-6 cm, special corners are stacked on top.

Paul and trim sideways

On the floor, the edged board 70 * 40 mm. The sex board is not recommended: small slots are needed, which will be able to swell on high humidity. Floor board with spike and groove there is nothing.

The sidewalls are also separated by a cutting board, only 70 * 20 mm. The lining was not used for the same reason: it can turn out if it is wet for a long time (fog, rain). I knocked the board on top of the finish, closing the ends of the trim, and you can put something on it.

Stock Foto Arbors of metal and tree: Almost finished

For this arbor from the metal made a rafter system of wood. It turned out rather arbor from metal and tree. You can accurately for the same principle to weld the rafter system from the profile, immediately welding additional drives. You can make a welded arbor from the same pipe with an arch. How to do a double arch, look in the video.

About how to make a wooden gazebo read here.

Stock Foto Metal arbors

In general, options for arbors from metal structures are very numerous: welding, forging, different materials that are separated by frames. Profile tube, round, steel and aluminum, there are even stainless steel options. All this is complemented by any form: from a square and a rectangle, to any complex shape. Metal is so plastic that variations are very and very much. Some of them are collected in the photo gallery.

The unusual shape of the roof and awning that decorative elements were visible, stretched from the inside

Metal frame, covered with an awning instead of a roof: the shadow is, nezharko and inexpensive

An unusual grill of thin pipes, painted white color gives the design ease

Very beautiful decor. This is not a metal gazebo, but a song in a metal

Another option of a multifaceted arbor

Art forging in the design of racks - elegant and exclusive

Round gazebo for giving under the blue polycarbonate - romantic

Simple Dachi Solution: Square Arbor, Covered Beige Polycarbonate

The rafter system can be beautiful

Unusual structure - a very interesting solution

We infrequently meet a metal gazebo from round pipes. Welder - Master of his case

Openwork arbor from metal - Summer option for giving or in the yard near the house

Highcard Drawing - Top View

Highcard Drawing - Front Piece

Hexagon open gazebo

Sketch of a metal gazebo with a polycarbonate finish at the bottom of a curly trim from pipes that are closed with dark translucent polycarbonate

Stock Foto Hex gazebow from metal polfil with partial wood trim

Gazebo from Metle with a barbecue

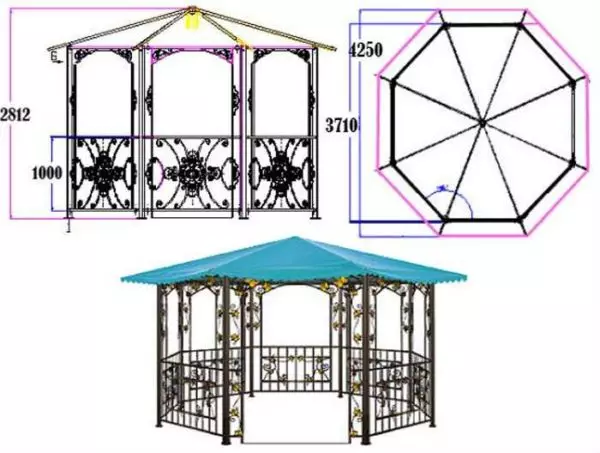

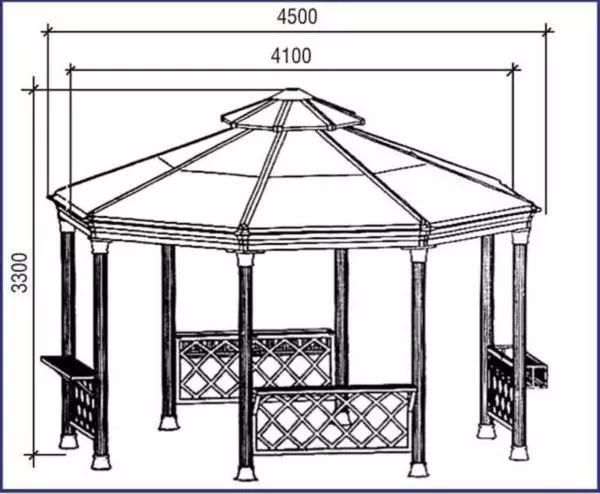

Drawing of an eight-marked arbor from metal with sizes

Sketch of octagonal metal gazebo with dimensions

Octahed metal gazebo

Round gazebo with metal frame and polycarbonate trim

Metal frame in combination with a toned polycarbonate

This is probably the simplest gazebo: two bent pipes that are fixed on the backs of garden benches. Polycarbonate is attached to the pipes. Summer garden gazebo ready

How to cook a gazebo for giving Look in the video.

Article on the topic: The main types of cranes and mixers in the bathroom