For giving, baths or kitchens, people often buy furniture in the store. But after all, it can be done independently and at the same time to spend much less than purchasing items in specialized salons. How to make a sofa with your own hands? What are the materials and tools for this? In order to answer these questions, you must first definitely decide on the option of such a sofa.

The sofa made with his own hands wins from the purchase not only at the price, but also in design.

It can be of different configuration, which depends on where it is planned to be installed:

- Simple design in the form of one block;

- an angular version of two small parts;

- Multi-element sofa, the main details of which allow you to collect several types of similar furniture.

You can independently make the first two options: they are simple and require a minimum of material.

The process of manufacturing the sofa with their own hands

Draft sofa.

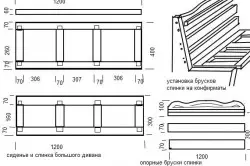

First you need to choose from the relevant literature the drawing of the future subject. Then make the sofa binding to the place where it is going to install. To do this, measure the length and width of the reserved angle, and if the dimensions are slightly different in the drawing, then they adjust them and draw them on the sheet of Watman sketch with the necessary dimensions.

Now it is necessary to collect the necessary materials. For these purposes, the timber, the trimming of which often remain during the construction of various utility rooms at the cottage. If they are not, then the desired material is bought in the construction market.

How to make a sofa with your own hands? To do this, purchase:

- Folon - it is sold in furniture stores;

- For the manufacture of cover and pillows - zipper;

- To cover the surface of the subject, material type of tapestry is bought;

- The construction market acquires a grid and a metal corner.

After that, work begins on the assembly of the base (frame). A timber is used for it. Its dimensions can be 700 x 2100 mm. Small trimming of the tree will go on legs - they will need four pieces. This is done in this way:

Sofa frame assembly assembly.

- In size from a sketch of a bar, a hand saw of the frame details are cut - two long rails (they must be equal to the length of the future sofa) and 2 short (width);

- For legs and handles use less thick material - you need 4 legs and two handles;

- Rims are knocked down by nails or use long screws;

- Then the remaining elements (legs and handles) are attached to it;

- transverse planks are cut from the boards - they will need several pieces, the main thing is that they enter into the frame;

- They are connected to the base with the help of metal corners and screws, and the frame mesh is installed on the frame, which the brackets are fixed;

- Now the parts are cut from the kitchen parts: two - on the length of the sofa and two - in the height of the future headboard;

- collect it with screws or welding;

- For the back will need a sheet of plywood or chipboard, which is strengthened with screws or screws.

Article on the topic: Application of glass winds in the bathroom, practical interior

Work on the basis of the basics is completed.

Making a soft upholstery on a sofa with their own hands

The coating technology includes the following components:Soft seats manufacturing pattern for sofa.

- Two mattresses are cut from the purchased foam rubber, the sizes of which should be equal to the sofa dimensions;

- their covering is made by the material obtained two covers connect the snake;

- From the same tapestry, tapes are made, with the help of which the mattress is fixed on the basis, these connecting elements contain velcro, and they are nailed to the frame in one end, and the second to the opposite point;

- Then 3 pillows are made from the foam rubber and close with snake covers;

- They are strengthened on the back with tapes from tapestry.

On this, the manufacture of this option can be considered completed.

Production of a sofa from finished shields

If a person has no experience with a tree or metal, you can try the method of manufacturing this household item from a material that is usually discarded. These are old doors. From their sash can work out a great sofa. Together with them the following details will be needed:

For the upholstery of the sofa and pillows will be needed.

- Porolon - it must be bought in the store;

- coating fabric (tapestry);

- residues from a wooden bar or hemp;

- Metal brackets that are purchased in the construction market.

The basis of this design and the backrest is 2 sashs from the old wood door, which served your time. Its surface should be durable, and otherwise the idea will not work. The door is cleaned of dirt, and it scrapes the old paint. Then the surface of the future base and the back is thoroughly polished by the emery. If there are cracks or deepening on it, then they must be embedded with the help of a brutal paste for wood. Again the door sash again and then covered with several layers of paint. The color of the coating is selected under the design of the room, where the sofa is assumed.

Article on the topic: Silk wallpapers: Liquid for walls, cargo in the interior, photo, plaster, reviews, video, wallpaper under silk

If there is an opportunity, then in the construction market or in a specialized store they buy veneer and glue and separate surfaces using a heated iron. In this case, the completed design will look more presentable.

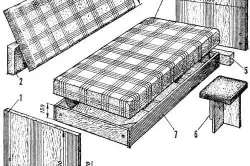

Sofa assembly scheme from shields: 1 - sidewall; 2 - additional pillow; 3 - pillow - backrest; 4 - retractable mattress; 5 - reference timber; 6 - Stand Stool; 7 - Bow base.

One of the door sash is installed on hemp or bars residues with building nails. And the second part is attached with metal brackets under the desired angle - the base is ready. Now it is necessary to make a mattress. It is cut in size with the size of the resulting frame and weathered with material (tapestry). If there is no possibility to purchase a new fabric, you can do without a bump or corporal, and with top cover with the material with the desired color.

The next step is the manufacture of pillows from the foam rubber, which was described above.

The manufactured mattress is laid on the base, and pillows are put on the back. All this is strengthened with ribbons and nails. Such a sofa can be installed in the country or in the bath. It will fit well into the kitchen interior in a country house or veranda in the country area.

Making a corner sofa

If a person makes a similar design for the first time, then you need to choose the easiest option. Binding it to the room and draw sketch with all sizes. For simplicity, you can abandon thickening connections and from use in the process of creating a design of expensive materials. To connect separate parts, it is best to apply screws. All wooden parts need to handle the skin before assembly. Initially, with the help of the jigsaw, all the details of the design of the chipboard are cut. Start an assembly from the left side of the sofa corner:

- Armrests are collected from individual parts, they are connected by screws;

- The frame of the left side is made from the bars with a cross section of 5 x 6 cm and amplified by transverse rails;

- On the base, the sheet of chipboard is fastened (thickness 14-18 mm), and then to the frame of the back should be attached to the fanwood screws.

Article on the topic: Water disposal near the house

Assembling the right side of the design:

Corner sofa assembly scheme.

- The bottom should be made in the form of a box, whose base is collected from the bars, and then trimmed by plywood;

- cut the side racks and attach to the main structure;

- If you plan to install a sofa in the middle of the room, then the back of the chipboard should be seen;

- The holes are drilled and the microlift is installed with furniture hats.

The next stage of work is the manufacture of foam mattresses. Their thickness should be equal to 10 cm. The sheets of the material must be glued to the base.

Start upholstery design. For all surfaces, it should be done from the cardboard, the fabric will be lighted. This is done with an invalid up. On the seams it is necessary to leave the allowance of 10-12 mm. If the material is sat down, then they are made even more. For recesses in the trim, holes are made in the design plates. There are hinges from a synthetic cord, and they are sewn to the main upholstery. The fabric is shot to the staple foam rubber. After coating, the fabric is ready to use.

A similar sofa corner can be put in the kitchen or in the living room. When using a less expensive upholstery tissue, it is possible to install it in the country or in a country house.

How to make a sofa corner even easier? Just put together at the angle of 90 degrees two small sofas made by technology described above.

Tools and materials that will be needed in the manufacture of design

Basic tools for making sofa.

- Wooden timber.

- Hemp and planks.

- Boards.

- Plywood or fiberboard.

- Microlift (for an angular sofa).

- Metal squares and corners.

- Sheet foam.

- Lightning snakes.

- Sewing machine.

- The cloth.

- Folds from doors.

- Stapler.

- Metal brackets.

- PVA glue.

- Paint, primer.

- Sandpaper.

- Manual saw and jigsaw.

- Electric drill with drills.

- Construction knife.

- Paint brush.

- Roulette and pencil, watman sheet.

The main thing in the independent manufacture of different types of sofas is the creation of a reliable basis (frame). Therefore, for the framework of construction, any solid material is used that can be easily treated at home. It all depends on the imagination and financial capabilities of a person who decided to independently make a similar product.

To achieve a positive result, it is necessary to consider possible options and choose the most suitable sofa for a particular room, and in its manufacture, adhere to the manufacturing technology and all these recommendations.