Photo

The bed is a special design designed for a full rest. It is necessary to approach its choice as carefully, since manufacturers offer standard solutions that are not always suitable for specific conditions. Therefore, today some prefer such structures to do their own hands. But not only the bed itself plays an important role, often it depends on how much use will be comfortable and convenient. The backs can be ready, but they are not provided for the design of the bed mattress, so such a back can be made independently.

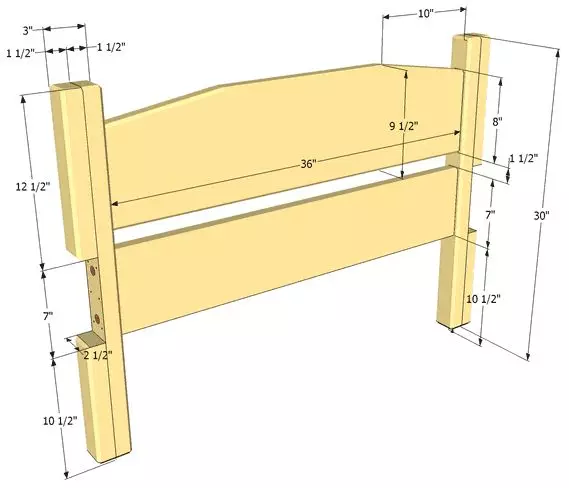

Bed back drawing with sizes.

It can be stationary, built-in back, downtown or replaceable, attached, which is attached directly above the case . The back of the bed, with their own hands modeled, must fully match the design, general interior. After selecting the type and appearance, it is necessary to determine the dimensions, exact shape, materials. The manufacturing process itself requires certain skills to work with tools, materials, but everything is not so difficult, as it may seem. It is only necessary to follow a simple assembly instruction.

Why do you need a headboard?

In which case, it may be necessary to need an additional headboard? Everything is simple here:

The headboard can be made of plywood, fabric and foam rubber.

- The sheet of plywood whose thickness is 8-12 mm, it will be used as a base for the future back.

- Porolon with a thickness of 50 mm or more. The size of such a sheet should be equal to the size of plywood base, if the back will be fused completely.

- Cuts of technical and decorative fabrics that will be used as lining and face finish. The size of the tissue is chosen on the basis of which dimensions will have a back (plus 15-20 cm for the sample). The lower part should be simple, but the front fabric is selected for the color of the interior. Pictures and ornaments, embroidery and appliqués are allowed. Today, you can find special furniture upholstery fabrics, artificial skin of the most different type and color.

- A set of fasteners, which include bolts, self-tapping screws, decorative nails, brackets, loops.

- A set of materials required for upholstery, including threads and needles, scissors.

- A set of decorative elements if they are used. These are buttons, ribbons, bows, seats of fabric and so on.

Article on the topic: Silicone sealant for the bathroom

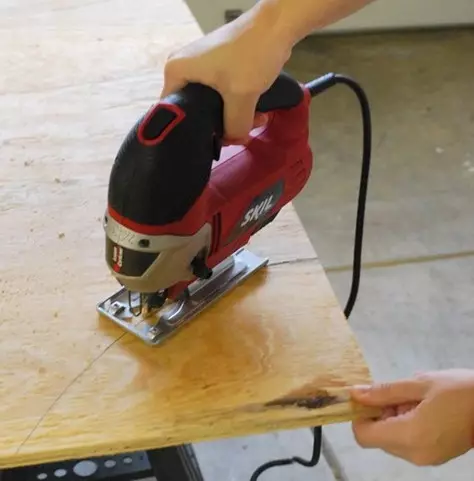

Cut the right shape of the head of the head can be pubisy.

From the tools for the work of the backrest, it is necessary to take the following:

- Electric jigsaw for cutting plywood slabs;

- drill with a set of drills of different diameter;

- Scissors, construction sharp knife;

- protective gloves;

- screwdriver, hammer;

- Rule, roulette;

- simple pencil;

- Furniture stapler.

The process of manufacturing the back

First you need to decide exactly what the back of the bed will be. To do this, you can take advantage of ready-made schemes and solutions or make a sketch yourself. It is best to use special programs for leaving the scheme that will allow not only to choose the appearance, but also calculate all the materials to the smallest detail. If there is not enough knowledge, you can contact any specialized firm or on a furniture factory, which is engaged in the manufacture of furniture to order. After the appearance of the appearance and assembly is in hand, you can start making.

If you have high skills in a carpentry business, you can make a carved headboard.

It is determined by what the sizes have the bed itself, what is its width. The headboard must have a width that coincides with the envelope of the case. Otherwise, it will be extremely uncomfortable to use it, and the appearance will not be so aesthetic.

A leaf of ordinary plywood with the necessary thickness (depends on the head-type type) as carrier part. First, such a sheet is cut to give it a rectangular shape. The width of the sheet will be equal to the width of the bed, and the height is the future height of the back. After that, the contour of the future product is applied to the surface of plywood with a simple pencil, on the bottom it is necessary to note the points where the mounting holes will be located. With the help of a drill, you need to drill holes, usually you need two on each side. It is necessary to take into account the design features of the bed, the possibility of fixing the backrest after its manufacture.

Article on the topic: Beautiful wet wallpapers: photos and 8 benefits

Electrvolovka The future back is cut on the outlined contour. It is necessary to clearly follow all the lines, since with further editing the size of the back will be slightly smaller. Next, emery paper should be carefully cleaned the entire surface, remove roughness, irregularities. The back should become absolutely smooth and beautiful. Exquisite will look a headboard from the fabric.

Decorative Bed Back

At the next stage, the upholstery begins, but it is necessary to immediately decide what kind of design. For soft backs, 2 options are applied:

The soft headboard will look beautiful and elegant.

- With a completely soft edge. For this embodiment, the foam with string is cut in accordance with the general sizes of the back. The headboard turns out soft throughout its area.

- With the preservation of the rigid edge. Mitigating material repeats the contours of the back, but its area is approximately 1/3 less than the area of the back, i.e. Complied indent. With a general decoration along the edge of the foam rubber, special decorative cloves with wide hats of different shapes are nailed. The rest is made up with fabric, artificial or genuine leather. If natural tree is used, then such an edge can be decorated with carvings. The soft edge will be only in the center, and on the edges - a natural tree with beautiful and elegant forms. It is necessary to have the experience of the thread, and you can simply order a ready-made frame that is in a soft material.

When everything is prepared, you should cut a piece of foam rubber required form, glue it to the base, to additionally strengthen the sides with the help of a bracket. With this method, the soft part does not move, it will be firmly standing still. When the soft part is ready, you can proceed to the backrest. The material for this should be chosen quite carefully, based on the appearance, requirements for operation, safety and hygienicness. The back should not accumulate dust, cleaning it should be carried out easily and quickly. Special attention should be paid to the level of wear resistance.

Article on the topic: Cleaning the gas column

Upholstery is carried out around the perimeter, if there is a need, then on the corners the fabric is neatly wrapped, cuts up. It must be stretching so that there are no savings, folds and other things. Stretch must be an average level. The cloth is attached differently, it all depends on the design of the head of the head of the upholstery itself. Most often, a construction stapler is used for such work, but for greater attractiveness around the perimeter, you can additionally strengthen special decorative furniture cloves that will keep the upholstery and provide a certain style.

Not only furniture cloves can be used to decorate the back, but also beautiful flat beads, a variety of ribbons, bows and so on.

All this should be thoroughly thought out that while working quickly and easily decorate the headboard in accordance with the idea.

The last step is the fastening of the finished back to the bed housing. Here, again, it all depends on what type the back is made for the bed with their own hands. For example, mounted attached to the wall surface, but the stationary already requires reliable fixation to the body of the bed. Most often, the headboard is screwed using self-samples to the housing, it can additionally be mounted on the legs, make comfortable hinges for fixing on the wall surface. In this case, the back will not fall at the most inopportune moment, its use will be safe and durable.

The headboard for the bed is a special design that is installed at the head. The headboard is always decorated, it is a peculiar face of the bed. But for standard models that can be bought in the ready-made form, the backs usually have an ordinary, boring appearance. You can collect the back of your own hands, which will become the central element of the entire setting of the bedroom, and it will be comfortable and comfortable, reliable. Decoration can be chosen any.