In the event that for various reasons, the acquisition of an exclusive round bed is problematic, perhaps the optimal output from the situation will be another option - a round bed with your own hands.

Round bed allows you to experiment with the bedroom layout. Thanks to its streamlined form, it can be organically fit into any part of the room.

Materials and tools

To create a masterpiece of his own production, the following tool will have to prepare:

Bed making tools.

- electrolovik;

- screwdriver;

- lace (up to 1000 mm long);

- roulette;

- furniture stapler;

- pencil;

- a hammer;

- Vacuum cleaner (for collecting sawdust).

In addition to the list, it is worth noting that, since the manufacture of a spring mattress at home is not possible, this important element of the bed is ordered in a special workshop.

Before starting work, a drawing of future creation is traditionally drawn up. In the proposed version, a round bed in diameter will be two meters.

For work, in addition to the above tool, it is still necessary to stock the following material:

- wooden bars (cross section 50x50 mm);

- plywood (10 mm thick) of this size so that it was possible to cut a circle of 2 m of diameter from two parts;

- organomet or fiberboard;

- dermatine or artificial leather, upholstery fabric - to taste;

- metal corners (25x25), 64 pcs., under the self-tapping screw;

- foam rubber not thick 40 mm;

- a large packaging of wood screws (4x35);

- furniture cloves (with decorative hats).

Round bed production sequence do it yourself

So, the work begins with the markup on the circle plywood with a diameter of 2 m or two semicircles. For this, the lace is used, which is fixed in the center of plywood. Further, the plywood is collected according to the outlined cord of the contour.

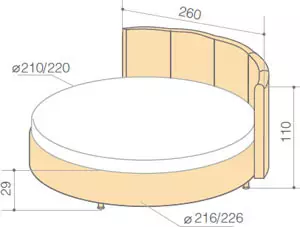

Dimensions of the Round Bed.

At the next stage, the cross is going to the circle. The work is carried out in such a way that the geometrically circumference of the diameter is as if crossed out by two perpendicular lines. Crosss are mounted in an amount of 2 pieces: one is attached under the bed, and the second on the floor. Assembling Crosss is carried out with the help of the corners, and the fastening of the plywood base to the upper crosset is carried out by means of self-tapping screws.

Article on the topic: how to install the doors of harmonica interior with their own hands (video, photo)

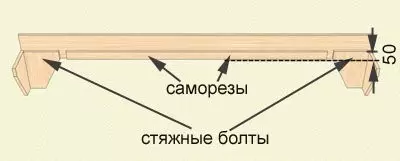

Long bars are fixed with each other.

From the same bar, legs are cut (in an amount of 9 pieces of 300 mm long), connecting crossmen among themselves. The legs are attached with the help of the corners: one is mounted in the center, and the rest - by radius.

Then there are another 8 small legs (400 mm long), which are evenly distributed around the perimeter and are mounted with self-drawing through. They are tightened by rigidity and firmly attracted corners. For a more dense fit to large legs, the rigidity ribs at the angle of 22.5 degrees . To determine this angle, the stub is used. Also for measuring the angle it is possible to use a simple, known from the school bench of the transport.

Finish podium bed

Scheme of fastening of legs and reference slats to sidewalls.

At the initial stage, the podium is trimmed by organic. The casing is made around the perimeter with a protrusion up to three centimeters. As a result, a small side is formed. Prepared bars are fastened with screws before forming an even cylinder.

Next, the harvested stripes of foam rubber are fastened with a stapler to plywood base. Do not remain without foam coating and legs.

At the next stage, the upholstery fabric is nailed, which is fixed not throughout the height of the legs. To hide the staple brackets, they are driven from the inside of the material on his junction, which is then turned out. Fastening the top of the material to the bed is performed similarly to the fastening procedure. The material is fixed in the bottom of the legs. The mount is made to each leg with the help of decorative carnations. At this stage, it's time to give the will of fantasy.

And at the final stage, having completed the manufacture of the bed with their own hands, a pre-ordered spring mattress is put on the finished bed.

At the same stage, it is worth thinking about the creation of a suitable bedspread, which will help to decorate and the rest of the beds of a centimeter gap at three. It is usually covered by a special ruffle made from a chopper material or upholstery fabric. As a ruffle, you can also use the remains of the fabric used in the manufacture of bed. The remaining tissue in this case is simply nailed with a stapler.

Article on the topic: Creating household items from juice boxes

To somehow diversify the decor of the bedroom, some experts advise you to create several ruffles. Then every time you change the covered, it will be possible to change the ruffles, picking up each new one's tone covered the most original option.

For the convenience of multiple fasteners, the ruffles are best fixed to the bed with velcro.

Thus, periodically changing the ruffles, you can experiment with the design of the bedroom and create all the new original images and styles of the room.