A good sofa has always been an integral part of home comfort. He remains for them today, despite the whims of modern interior fashion, which is not always a male to the traditional furniture attribute.

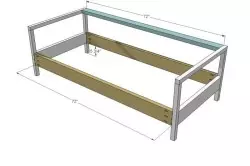

Sofa device diagram.

Perhaps for this reason, manufacturers are not very eagerly engaged in low-cost furniture, paying more attention to the models of complicated and expensive. In this regard, the ability to make a sofa frame with their own hands becomes even more relevant, without which it is impossible to make a sofa entirely.

Do not make complex designs, especially if a joiner wants to do a beginner. It is always necessary to start with a simple. Especially since simple often turns out to be the most reliable.

Materials and tools for the manufacture of a sofa frame

Sofa frame diagram from bar.

To qualitatively execute the frame assembly, it is recommended to prepare the following materials and devices:

- Chipboard;

- Furniture plywood;

- wooden bar;

- polished board;

- carpentry glue;

- electrolovik;

- drill;

- electric screwdriver;

- a hammer;

- screwdrivers;

- chisel;

- wood hacksaw;

- construction knife;

- metal corner;

- Elements of fasteners (nails, screws).

What to pay attention to when preparing for work

The frame is the basis of any object of furniture, so it is necessary to pay particular attention to its quality. And it should be done already with the preparatory stage of the production of the sofa.

Scheme of the back and seats of the kitchen sofa.

First of all, it should be very thoroughly find out all the subtleties of this process. You can, for example, get acquainted not only with special literature, but also use personal experience gained in the inspection of various types of sofas, on which the master ever had to sit.

Moreover, it is advisable to initially refuse the thought of creating something superpower and unusual. If you do not satisfy a more or less simple option, it is better to immediately contact the furniture store, trusted by experienced and reliable in this segment of furniture manufacturers.

Article on the topic: Primer for walls under painting with your own hands, the benefits of using the material

Thus accumulated information and observations should be embodied on paper in the form of a carefully developed project. It should reflect the main concept of the sofa, as well as the most important design parameters, including the height and design of the legs, the angle of the backrest, the thickness and texture of the furniture upholstery and even that, will the product stand on rigidly fixed legs or make it equipped with rollers for Mobility.

The main thing is to remember that the better the drawing is more clearer, the more significant details, proportions and tolerances are reflected in it, the easier and will work faster.

Sofa sofa scheme.

Naturally, the most important point here is correctly selected frame size as the basis of the entire product. And for this immediately need to decide on the room in the room, which will take this corner of a comfortable stay in the future. After all, it will be very disappointing if, as a result of the manufacturer's carelessness, it is necessary to install it not where it was planned, thereby disrupting the general finished style of the interior.

The next no less important point in preparing for work is the choice of high-quality building materials from which the sofa frame will be made. From the technical characteristics and operational capabilities of all these jumpers and stiffeners as a result, the general performance of the specified furniture product will be dependent.

In particular, if it comes to a wooden bar from which the framework is manufactured, then it is necessary to turn to the solid wood. Although these elements will be hidden from human eye in the depths of the sofa, they should be fairly smooth, not disrupted, not deformed, not to mention that these Bruusyev cannot have more serious defects.

Sofa frame sequence

Making a sofa seat.

It is proposed to make a fairly simple wooden skeleton of the sofa with their own hands in size corresponding to the standard product, the dimensions of which are: length - 1.9 m, the height of the back - 0.8 m, the height of the seats (without taking into account soft pillows) - up to 0.3 m.

Article on the topic: Canopy for mangala do it yourself

The direct production of the sofa frame begins with drinking its base. This is done according to the drawing (ready-made template) from plywood sheet. For this purpose, you can also use furniture shields that remained from furniture already in use.

It is convenient to drink a basic frame element with an electric jigsaw. Moreover, if the design as a result of all the industries turns out to be quite large, then the base of the frame is recommended to divide into several parts, which will be processed separately. However, all of them, without exception, should be cut and processed in such a way that when dutching during the assembly, they have connected without the slightest problems.

The finished skeleton base is a rectangular fragment of thick, carefully polished furniture plywood. Its length and width are defined by a specified project. If the manufacturer has a desire to shelter not only the top, but also the bottom of the frame box, then such identical plywood rectangles need to do two pieces.

The next stage in the process of manufacturing the frame - cutting horizontal partitions and vertical racks and assembling them into the frame box. Cut the specified structural elements follows from bars in accordance with the dimensions recorded in the drawing and exactly the corresponding dimensions of the plywood base prepared in advance. For a reliable connection of the conjugated parts, the excavations are cut into their ends, which form a spike-groove clutch system.

Frame size scheme.

Then the bars are grumbling and covered with a mourn and varnish, if necessary. After complete drying of the paint coatings, ready-made partitions and racks according to the designed scheme are connected to each other. For additional strength and stability, the composite components of the framework with the help of a screwdriver are fastened with metal corners.

A plywood-based foundation prepared in this way. It is securely attached to a rectangular frame with a special joinery of the adhesive or by means of screws. All fasteners should be recessed in the thickness of plywood in order to avoid in the future hooks and breakthroughs of soft pillows.

Article on the topic: Repair of locks in metal doors in detail

The next stage is the manufacturer of the back for the sofa. It should be noted that the dimensions of this design element should be fully combined with the dimensions of the sofa base. And the back is mounted in the same way as the rest of the frame, if, of course, it is not expected collapsible (folding) furniture. In particular, in this case, the upper and lower longitudinal bars make a width of about 8-9 cm, a few vertical racks - a height of 40-45 cm.

It remains to connect the finished back and horizontal part of the frame. It is done using a metal corner, while the corner is located at the bottom behind the back. As for the angle of inclination of the back, he is chosen arbitrarily by the master itself.

Several useful tips

A beginner joiner who decided to make a sofa for the first time with his own hands, it is better to choose a classic rectangular frame version. You can engage in angular or folding models, already obtaining some experience in making sofas.

When choosing building materials for work, it is necessary to especially carefully consider their environmental safety. In this sense, materials purchased in specialized construction supermarkets give a large guarantee.

If the cutting and sawing of wood for the sofa frame at home presents certain difficulties, this operation can be ordered in many building materials stores.

All frame elements are recommended to do from the dried pine bar.

When fixing parts by self-draws, they are undesirable to screw in one line. Such a technique is fraught with the formation of longitudinal cracks.

If all the recommendations and warnings are taken into account, the joiner will be able to count on a great result - a comfortable and pretty sofa, which will want to rest as often as possible.