How does the lifting bed make with their own hands? Currently, owners of small-sized apartments have found the opportunity to solve problems associated with a small bedroom area by installing a lifting bed.

Lifting bed is a real find for a small apartment and an excellent alternative to uncomfortable folding sofas.

This bed one bed is attached to the wall. In the morning the foundation is cleaned - raise up. At night, the product is lowered into a horizontal position for sleep. This ergonomic bed can be made independently.

What is the design of the bed?

Constructively, the bed consists of the base and frame, which can be fixed in a vertical position. To the bottom of the frame attached a sleeping place with the help of a lifting mechanism. The bed is attached to the frame with one end and in the raised position has a view of the cabinet. It is necessary that in the folded position the design is stable.

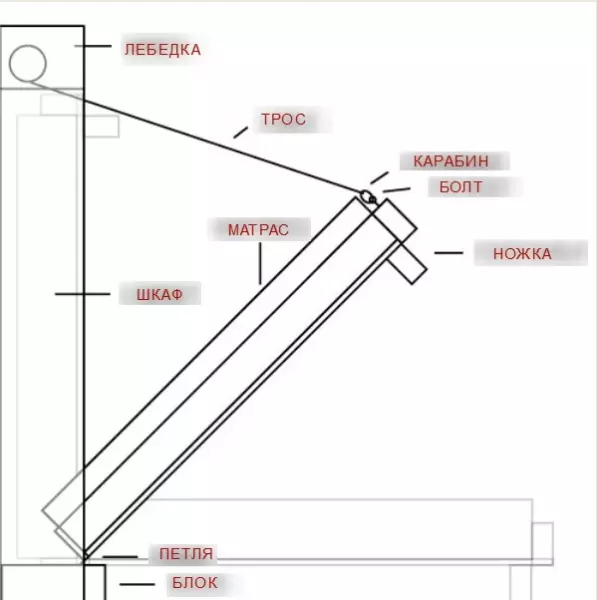

Figure 1. Lifting bed design scheme.

The design of the bed consists of the following elements:

- lifting mechanism;

- bases;

- Cabinet box.

To make a bed with your own hands, the drawings are mandatory. In fig. 1 shows the scheme of the lifting bed design, which shows the lifting mechanism consisting of cable, winch, bolt, carbine, loop. Here are shown mattress, wardrobe, block and leg bed.

The base has dimensions that correspond to the sizes of the orthopedic double mattress. It must be located close to the base and take it when necessary.

Making a lifting bed with your own hands

Production of the product starts with the acquisition of necessary materials and tools.

Materials and tools:

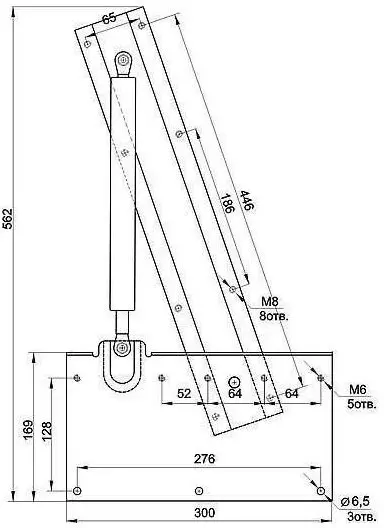

Figure 2. Scheme of the lifting mechanism.

- orthopedic mattress;

- Set of sawn timber;

- Perforator;

- wrench;

- Metal corners;

- Anchor mounts;

- confirmates;

- self-tapping screw;

- sandpaper;

- drill;

- drill;

- screwdriver;

- furniture handles;

- accessories;

- decorative furniture lining;

- Super glue;

- pencil;

- roulette;

- iron;

- rag;

- building level.

First of all, it is necessary to purchase a standard double orthopedic mattress with dimensions of 2000x1600x220 mm.

Article on the topic: Connecting a phone socket

After that, they purchase the necessary lumber from a chipboard with a thickness of 18 mm:

- two sidewalls of the cabinet with dimensions of 2282x420 mm;

- bottom and top of the cabinet 1695x420 mm;

- Facial panel 1685x2235 mm;

- two sidewalls of the strapping frame 2038х150 mm;

- Front and rear parts of the strapping 1605x150 mm;

- Two ribs of hardness 1690x350 mm.

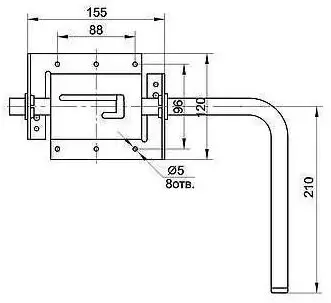

Figure 3. Detailed drawing of bed legs.

To handle all the edges of the boards, you need to attach a self-adhesive edge to the end of the board and try the iron, and then pick up for a better gluing with a dry cloth. Then an extra part of the tape is cut and processed ends with emery paper.

In fig. 2 shows the scheme of the lifting mechanism with an indication of the desired size. In fig. 3 shows a detailed drawing of a bed leg with all sizes. These drawings will be needed when ordering the lifting mechanism and choosing the load of gas springs.

After that, they start assembling a lifting bed. The sidewalls of the cabinet are overhead details, the remaining elements are internal. The assembly begins with the fact that the drill of 5 mm is drilled by the ribs of the cabinet, top and bottom.

Then they fix the frame with the confirmates and install it on the wall. With the help of metal corners, the frame is fixed with anchor bolts.

When mounting the frame to the wall it is necessary using a construction level to clarify the strict verticality of the lateral parts and the correctness of direct angles between the box elements.

Then on the sidewalls are mounted fixed parts of the lifting mechanism. Then they drill and collect the strapping of the base.

The plates of the mattress are fixed according to the drawing to the strapping. Screw to it and moving part of the lift. At the top of the strapping drill holes under the legs of the bed. Then the fastener of the front panel is performed. At the same time, it is necessary to carefully check all sizes using a construction level.

First, the facade is fixed on four furniture corners, then the level refine the dimensions and then screw the remaining corners and connections. Then the hidden legs are inserted into the necessary holes. After that, the facade is assembled.

Article on the topic: Application of the hydrophobizer with their own hands

On this assembly of the lifting bed-cabinet ends. Now you need to finish the facade with handles and paste decorative furniture lining.

The lifting bed made by their own hands on this technology will be durable, reliable and will last for a very long time.