Bedroom furniture can be made with their own hands from various materials based on the requirements of the overall interior and environment. One of these options is a metal bed, with your own hands, which is not so difficult to do. You can choose a model suitable for almost any style.

A bed for a bedroom from metal will serve a much longer ordinary wooden bed.

This design can be a real decoration for any interior, it will not only complement the design, but will also become a key element. To assemble such a bed yourself, it is first necessary to make a sketch with an indication of all sizes, then prepare the appropriate materials and tools. If there is an opportunity, then work is best in the workshop, since the welding machine and Bulgarian and Bulgarian will be used during the assembly..

How to determine the dimensions?

To assemble a beautiful and comfortable bed, you must first determine its dimensions. Usually for one person is quite a width of at least 70 cm, but it is best to 80-100 cm for proper comfort. When selecting the model, one-bedroom or double design is taken into account. To determine the bed length, an average height of 170 cm is usually taken into account, but it is best to do 190-200 cm, although everything is individually.

During the selection of the sizes of the future bed, a number of factors should be taken into account:

Measuring and marking tools.

- The presence of free space in the bedroom.

- Mattress sizes. Today you can buy mattresses of any size, but the standard find is much easier than ordering according to individual standards, which will cost much more. Of course, the mattress can be made with your own hands, but if there are no such work skills, it is best to first get acquainted with which models are presented on the market, choose a certain size. Already on the basis of this, you can make a sketch of the bed, if necessary, changing any parameters.

- The design itself can be solid, but experts advise it to divide it into two parts, i.e. to collect 2 separate frames. If necessary, the bed is easily versed for transportation, then going. During the drawing up drawing, total sizes are divided by half.

Preparation for work

To make a metal bed with your own hands, it is necessary to pre-draw calculations and purchase all the materials that are required for work. Materials will need steel pipes, square-section profiles, chawliers, corners.If there is no experience in cutting metal, it is best to take advantage of the ready-made specification so that in the workshop or when buying the material has already been cut into the required segments.

In this case, the work will be made as quickly and efficiently as possible, no waste will remain. If the metal is purchased on a lot of metabolism, then it is necessary to add a total of 10% on the climb.

Article on the topic: The toilet flows from below

After that, you need to make a list of all tools that will be necessary for work. The main tool will be a welding machine, with which the structural elements will be connected. When working with such equipment, security rules should be followed, the work itself must be performed in a spacious room, use personal protective equipment.

Consumables

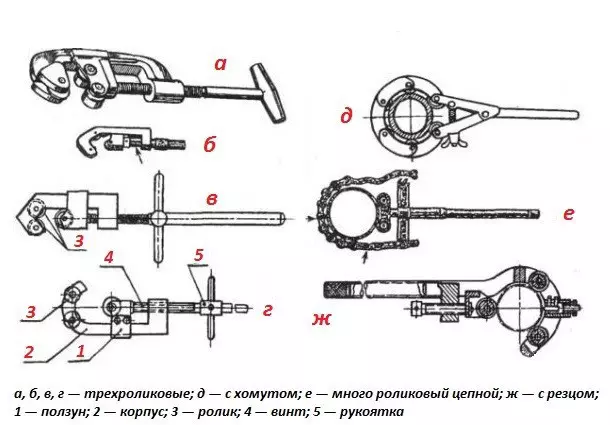

Without pipe cutting, the installation of a metal bed will be impossible.

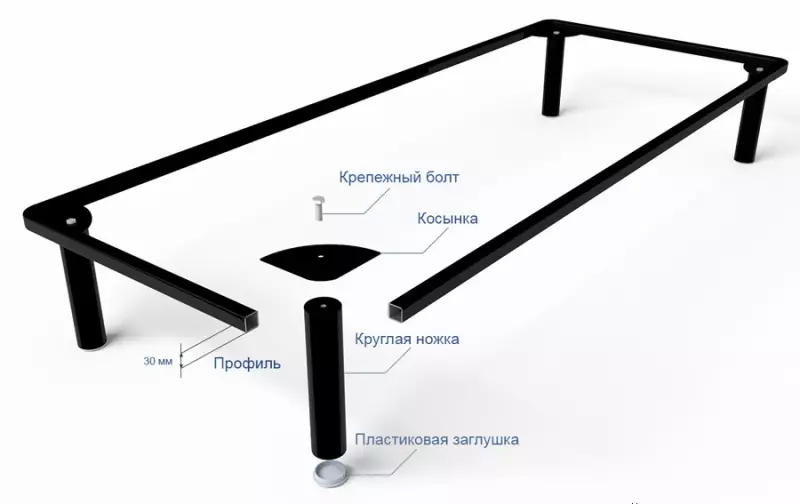

The bed will be made of metal profile pipe with dimensions of 20 * 20 mm, the bed frame will be made of steel channel 65 * 32 mm. For the spyers and plugs, a metal corner of 40 * 40 mm is needed and with a thickness of 2 mm. For more information, the specification of the materials for the manufacture of beds is as follows:

- For the backrest racks: Steel pipe 900 * 20 * 20 mm - 4 pcs;

- For the upper crossbar of the back of the bed: steel pipe 2000 * 20 * 20 mm - 2 pcs;

- For lower crossing back: steel pipe 800 * 20 * 20 mm - 2 pcs;

- For a foot rack backrest: steel pipe 600 * 20 * 20 mm - 4 pcs;

- For lower foot shifters: steel pipe 1680 * 20 * 20 mm - 1 pc;

- Vertical foot parts: Steel pipe 250 * 20 * 20 mm - 2 pcs;

- Transverse elements for the back: steel square tube 800 * 10 * 10 mm - 16 pcs;

- Tsargi: Steel Schwell 2000 * 65 * 32 mm - 4 pcs;

- Central Bench Brackets: Steel Channel 120 * 65 * 32 mm - 2 pcs;

- Side brackets for: Steel Channel 120 * 65 * 32 mm - 4 pcs;

- Face elements for frame: steel corner 1000 * 40 * 40 mm - 4 pcs;

- The base for the mattress frame: steel strip 2000 * 25 * 2 mm - 2 pcs;

- Base frame for mattress: steel strip 1000 * 20 * 4 mm - 6 pcs;

- Santers for racks: Steel sheet with a diameter of 25 mm and with a thickness of 2 mm - 10 pcs;

- Plugs for upper transverse elements: Steel sheet with a thickness of 2 mm and sizes 20 * 20 mm - 4 pcs.

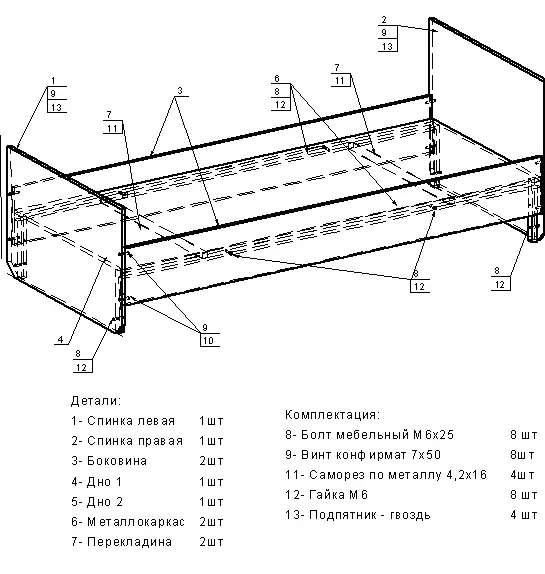

Metal bed diagram.

The size of the future design will be like this: the length is 190-200 cm, the width is 80-200 cm. The height of the mattress will be 20 cm, the spring blocks are better to take independent.

If you take into account the amount of material in the sweepage, then the total calculation is:

- steel square pipe 20 * 20 mm - 12 m 50 cm;

- steel square pipe 10 * 10 mm - 14 m;

- steel strip 20 * 4 mm - 6 m;

- Steel band 25 * 2 mm - 4 m 50 cm;

- steel corner 40 * 40 mm - 4 m 50 cm;

- Steel Schwell 65 * 32 mm - 11 m.

Article on the topic: Balcony waterproofing from the inside and elimination of leaks

Tools for work

To make a metal bed, you need to prepare the following tools:- Bulgarian for cutting metal;

- The welding machine, with which the individual structural elements will be connected;

- drill, 9 mm drill, designed to work on metal;

- roulette;

- Metal coal for checking the corners of the design;

- a square file (it may be necessary when processing holes for bows of structures fasteners);

- Metal surface stripping brush before painting;

- sandpaper (you can purchase a special set for metal work);

- paint brushes;

- Special primer for metal surfaces;

- Paint-type selected type (it is possible to use varnish as an finishing coating).

Bed making

Mounting frame of a metal frame of a bed.

After all the design elements are ready, it is necessary to make brackets from scope string. They will be needed for fastening the frame of the bed. The brackets are welded with a continuous seam to the back of the bed along its entire length, as it is later that they will be the largest load. At first, small brackets are welded, after them are large.

When work with the back is over, it is necessary to start making the frames that will be two. Subsequently, such a bed will be much easier to disassemble for transportation than a design that has only one frame. The sequence of work is maximum simple. It is necessary to combine the frames prepared for the frame at right angles. You can use for the control of a special square. You will have to check the diagonals, after which it is welded on the joints.

More detailed this process will be:

The main types of Schaweller.

- The brackets that must have spikes for fasteners are manufactured from the rancher. Total will need 2 central parts and 4 side. Metal is cut by a grinder. During cutting, it is necessary to ensure that the SCOS is saved in 5 degrees for each spike.

- After cutting, the brackets are welded to the backs of 35 cm from the floor level.

- For the frame it is necessary to take a channel and a metal corner. From the corners will be made end parts of the frame, and the sings will make from the rancher.

- In the frames it is necessary to drill special retarded holes in which the spikes from the brackets will be attached. When places, it is necessary to observe all the sizes as accuracy, since it will be difficult to redo the design. The diameter of the holes should be 9 mm, if necessary, they are adjusted under the shape of the spike with the hardware for the metal.

- Metal bed further assumes a special lattice device under the mattress. For this, steel strips (6 transverse and 2 longitudinal) are welded to the ready-made frame.

- The last time the steps, plugs for bed columns are welded.

Painting finished design

After the metal bed is collected, it is necessary to start work on the preparation of the decorative design. Decor options a huge amount. Usually metal structures are painted, the color is selected, based on the overall setting. To do this, you need to perform such simple actions:

Article on the topic: Chair for feeding with your own hands: Step-by-step instructions

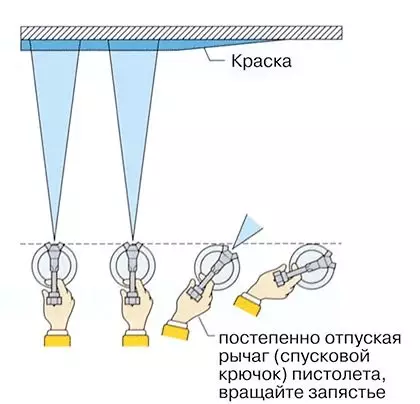

Metal painting circuit with a brushes.

- The surface of the metal is preparing a special rigid brush, after which it is processed by a grinding machine. It allows you to remove slag tracks from the surface, make it smooth and smooth.

- For a smooth surface, special discs are used, the thickness of which is greater than that of standard cutting, they are all calculated withstanding transverse loads. With the help of such disks, even the most convex welds are perfectly removed.

- After the primary processing is completed, it is necessary to perform a thin grinding of the metal, polish all the surfaces of the bed. It is from this that will depend on the quality of preparing for painting.

For painting, you can use any color, but attention should be paid to the overall setting. For example, if the interior is modern and strict, then for the bed it is best to select monochrome and non-lass shades. If there is a large amount of dark tones in the finish, the bed is also painted with a dark paint composition.

Before the painting itself, metal should be coated with a layer of primer, which will provide better paint adhesion with the design surface. The primer mixture is selected of this type, which is suitable for working with the metal, is applied with a soil brush. When this layer is dry, sandpaper should be treated with the surface, remove all irregularities.

A scheme of painting a metal bed with a pulverizer.

Painting a metal bed is recommended to perform with an airbrush by setting the torch diameter to the required size. In this case, painting will be completed in the shortest possible time, it will turn out to be high-quality, and the paint consumption will decrease several times. But if there is no airbrush, it is possible to paint the design and a thin brush. The number of layers - 2-3, each thickness should not be too large. The brush should be chosen only high-quality, otherwise, during work, hairs will fall out of it, which will strongly spoil the appearance of the furniture. Each layer must dry, after which the next one is applied. If there is a need, then after drying the paint is applied layer of varnish.

When using polymer coatings for painting the bed, the work sequence will be as follows:

- coating with liquid cold zinc;

- preliminary impregnation;

- a layer of primer;

- a layer of paint representing a mixture of acrylic and polymer fluorine-containing rubber;

- a layer of printed paints (acrylic and polymeric);

- Finish layer of acrylic-polymer paint.

Metal bed do it yourself - it is beautiful and fashionable, although it is necessary to have skills to work with such material, with a welding machine. The design itself is extremely simple, but attractive, suitable for any bedroom style.