Manufacturing holes for the installation of the mixer

Currently, there have been many models of miles having a symmetrical shape. Such sinks are extremely comfortable, as they can be installed both on the left side and on the right.

Some models of modern mixers: A - Faucet for kitchen sink; B - faucet for kitchen sink with a shower grid on a flexible hose.

In order for the sink to be installed on any side, it does not exit a mixer in it.

It is assumed that the hole for the mixer of the required diameter will be done immediately before installing the plumbing. On the one hand, it is very convenient, because it is not always possible to choose a wash with a ready-made way out due to discrepancies in the parameters.

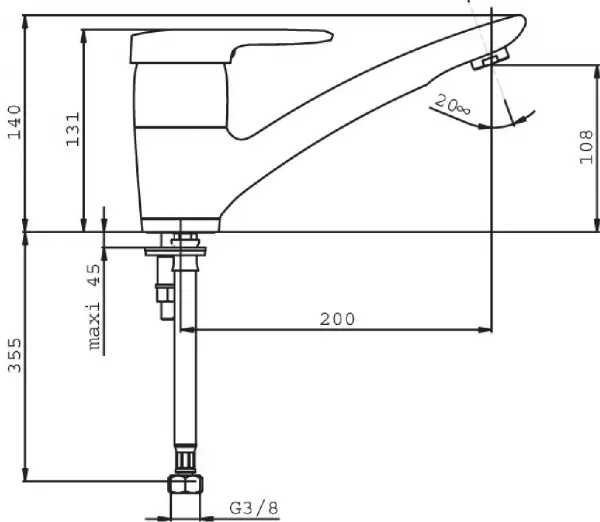

Faucet for kitchen sink on one hole: drawing.

For the most ready-made sinks for the kitchen, the factory outlet is 32 mm, while the diameter of the mixer can be more than 34 mm. Currently, mile options are produced without a ready-made way out of stainless steel and ceramics. For many, it may seem just an impracticable task for many of the necessary diameter, but in this case there are a number of measures that can be taken.

In some points of sales of such moels, it is quite possible to use the services of specialists: they will select an output under the mixer of the desired diameter, will make it all with the help of special tools. But such services are not provided everywhere, and the owners of the miles without the finished way out under the mixer will have to make it independently.

Immediately it is worth saying that it is possible to make a neat hole only in stainless steel, while on the kitchen sink from granite or ceramics, experiments are fraught with, since the material can crack.

Article on the topic: Beige color in the interior: Choose a suitable shade and learn to combine with other paints (40 photos)

Work on the production of outputs for communications in the ceramic sink must be carried out as neat as possible so as not to spoil the appearance of the sink. If possible, you need to purchase tools: Special cutters for the manufacture of holes are sold for stainless steel, it is best to use drills with diamond spraying for ceramics. Drill ceramic plumbing can not be a regular drill, as ceramics will just crack. However, it is quite possible to do with some infrident means, but you need to act extremely gently.

Stainless Steel Mixer Hole

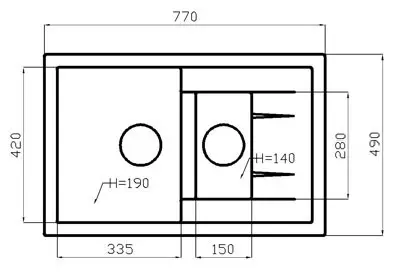

Scheme of exemplary sizes of kitchen sink.

There are several proven ways how to drill a smooth hole in a stainless steel. Immediately it is worth noting that it is impossible to do the output under the mixer in the already installed plumbing, since because of the support on the table top there is a chance that the plumbing will crack. Before carrying out the work, the car wash needs to turn over the bottom so that all of its edges relied on the surface of the table, and only then proceed to the work.

If you can buy or rent a special cutter to do the holes, work will not work. First of all, you need to make the initial hole with a drill and a drill of 10 mm. Next, the cutter screw is inserted and with the help of 2 keys is delayed, such a way it turns out that the metal is squeezed from 2 sides and is pressed by the press method. The diameter may be different depending on the type of cutter used. If there is no possibility to purchase a special device, you can resort to other methods.

So, in order to make a way out for communications of the desired diameter in a sink from a stainless steel without the use of special means, the following tools and materials will be needed:

Kitchen mixer device diagram.

- marker;

- assembly tape;

- a hammer;

- Round file;

- Kerner.

So that the diameter corresponds to the norm, first of all it is necessary to make the circle of the desired size and shape from the assembly tape. The carved circle must be attached to the selected place under the mixer and cover the marker to cut a smooth hole in the future. In addition, you need to note the center to do the initial opening of Kerner. Kerner's edge must be sent to the center of the circle from the mounting ribbon and light tapping to break the initial opening. If there is a drill, you can drill it. Next, the initial opening must be expanded with a circular file to the previously marked borders.

Article on the topic: Characteristics and application Sealant for wooden floor

Just drill the output under the mixer in a sink from a stainless steel is not enough, as the edges can turn out to be curves, and to align them later it will be very problematic. After it is output under the mixer of the desired diameter, it is necessary to carefully sand the edges of the spike, then you can start the installation. In order to prevent the metal oxidation in the future, the edges of fresh drink should be treated with sealant. After it is frozen, you can start setting the sink.