The washing machine is usually purchased with the calculation that it will last at least dozen years, but it does not always happen. The service life of the washing machine depends on many factors: the conscientiousness of the manufacturer, the frequency of use and compliance with the rules of operation.

Careful care includes not only the choice of high-quality equipment for washing, timely cleaning and prevention of scale of scale, but also control over the state of the internal elements of the washing machine.

One of these elements is a gland. About what it is and how to maintain it in working condition, you can find out by reading this article.

What is a gland and why smell it

The gland (or, as it is more correct to call, the gland device) is a detail of the mechanism that serves the sealing element between its two parts, one of which is mobile, and the other is not. The gland is usually made from rubber, so it does not only compact, but also seals the connection.

In the washing machine, the glands are needed in order to protect bearings from water from entering water. They are located over the bronze sleeve, which, in turn, is fixed by the semi-axis. The glands must be changed along with the bearings so that the compound always remains dense and sealed.

A semi-axis is a rotating shaft on which the tank and the drum of the washing machine are fixed. Rotating, the shaft comes into contact with the inner surface of the gland. Constantly exposed to friction, this detail is rapidly flashes. To slow down this process, a special grease for seals is used, which provides sliding, thereby reducing friction. If it does not update the lubricant on time, the oil seal will fuse and starts to pass water, which will lead to the bearing breakage and to the failures in the work of the washing machine.

Article on the topic: Bathroom design in Khrushchev: Competent approach and features

Requirements for lubrication

There is a category of the owners of washing machines, which, instead of specialized accommodation makers, prefers to use folk remedies, such as vegetable oil or fats. Such a decision is definitely more economical, but at the state of the mechanism it affects not the best way.

Therefore, we strongly advise you to use only those funds that meet the following requirements:

- are moisture-resistant, that is, they do not lose their properties while in constant contact with water;

- have no aggressive chemical composition, which does not destroy the surface of the gland and the metal shaft;

- Resistant to temperature drops, do not disintegrate and do not lose their qualities, exposed to heating;

- They have sufficient density and viscosity, so that for a long time not to wash off with water.

What better use: tips on choosing

Lubrication for the seals is usually sold in stores specializing in trading with washing machines or spare parts for various types of household appliances. The price of this consumable material may be unpleasant to surprise you: this is due to the fact that this is a good product that is on sale is quite difficult.

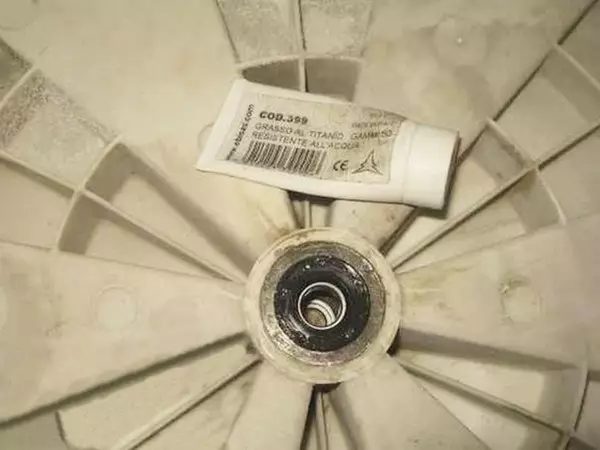

Often, household appliances manufacturers are engaged in the release of lubricants for the seals, which are intended directly for this brand of washing machines, but in reality are suitable for all models. Most lubricants are interchangeable, you only need to pay attention to the main component of the composition. Silicone and titanium lubricants are popular with popularity, which are well repelled water and are able to withstand temperatures up to 200 degrees.

Instructions for use

To replace the gland or update the lubricant, you will first have to almost completely disassemble the washing machine, pull out the tank and remove the drum from it. About how to do this, we were told in detail in the article "How to remove the bearing with a drum washing machine?"Changed the wear bearings and glands to new, you need to take care that they will serve as longer as possible. To do this, we need to properly apply lubrication to the gland. At first, the lubricant is applied to the outer surface of the gland with a smooth, thin layer. Then proceed to the processing of the inner surface. Here the layer should be a little thicker. After that, the gland can be installed in place.

Article on the topic: How to make a septicch without pumping for giving

Visually and in more detail, this whole process, see the next video.

How can I replace the lubricant?

Sometimes it is not possible to find a special lubricant for the glands. In this case, the craftsmen replace it with an oil-based product, for example, solidol or lithol. Experts warn on the use of data from data, as they contribute to the rapid wear of the glands. Such lubricants are used in the automotive business, but their household appliances cause more harm than good. Therefore, it is better to spend time and money for the purchase of specialized funds that have a resistant effect and are completely safe for washing machines.