In modern apartments and homes there are many objects of equipment and electronics. And often the question arises about where all this is placed. In addition, a table is very often needed in the premises, in order to put books, magazines or just drink tea. For these purposes, an excellent option is a table bedside table and a wooden table.

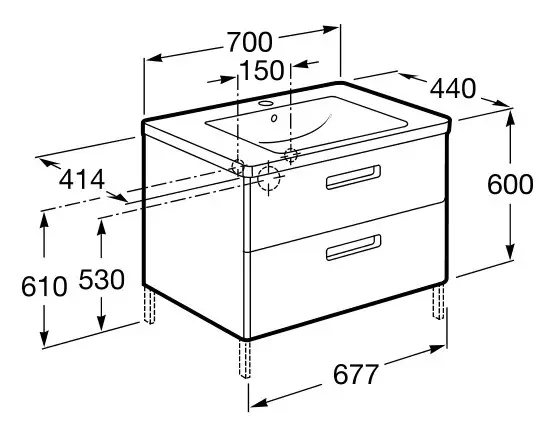

Size diagram of the sizes.

Of course, you can buy a ready-made model in the store. But in this case you will have to spend additional money. Moreover, not always the presented specimens are suitable for buyers in style. In such a situation, an alternative can be made by an alternative. Consider in detail how a bedside table is performed with your own hands.

Timber manufacturing technology

As already mentioned, the material for the manufacture of the bedside can be a tree.

Initially, you need to think about what size should be your future stands.

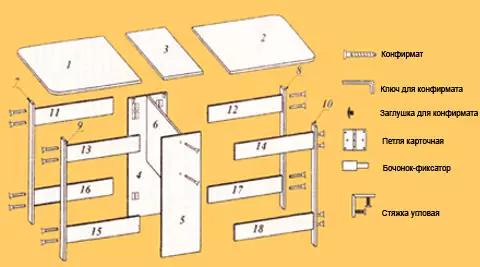

Diagram of device of the couch.

Transfer all the calculations on paper and only after that proceed to the purchase of material.

For internal filling of the cabinet you will need glass, the thickness of which should be 4 mm. In addition to glass, purchase screws for furniture, PVA glue for joinery, decorative edging and wheels.

- Draw on wooden panels details of the bedside tables and cut them out by means of hacksaw or jigsaw. At the same time, it is necessary to additionally leave about 4 mm from each edge. As for the arcuate details, it is originally necessary to cut in the form of a rectangle, after which it is to transfer all roundness to the wooden panel using a tracing. As soon as you do it, take a handwheel in your hand and with a high proportion of accuracy cut the part along the arc line.

- Make sure that the planes of the parts are perpendicular to the ends and so that they are in the end did not work out. If you are using a tree panel without lamination, they need to be good to open. To do this, you need to take a sandpaper and attach it to a small bar. It is them that you need to walk along the surface.

- After the tree surface is fully ready, mark on it places for holes and drill small holes. It is important to take into account the fact that all holes must be located from the edge further than 40 mm. Which diameter will have a drill, directly depends on the size of the dummy.

- Next, you need to stick to the surface of Watman and scratch it about twice the black paint. On the ends of the parts, cover the edge ribbon with the effect of lamination, to purchase which you can in any specialized store. This tape is attached to detail through an iron. You need to stroke the edge through paper. After all the listed circumscribe all the details of varnish.

- If your parts are fully prepared, you can proceed to assembling the bedside tables. The first thing you need to do is to clean the holes from the pollution accumulated in them. The fastening of parts must be carried out by means of adhesive composition and ducks. In addition to them, in the process of assembly, you will need screws for furniture. After you set the side panels, the bottom and top, you need to fix the parts from the back and set the back.

- Next, you need to measure all the angles. Details must be arranged at an angle of 90 °. To the bottom bedside tables attach 4 special wheels.

- In the internal holes insert the shelf mounting. In addition, mount to the walls of the loop, so that the doors can be installed. You will need to install glass shelves and fasten to the doors of the handle. And the last thing you need to do is to upgrade the end of the finish profile.

Article on the topic: how to glue wallpaper under painting: the right approach and 9 materials

How to make a table of wood?

Wood table device.

First of all, you will need a smooth slice of a log. It will subsequently play the role of the tabletop.

- From the bottom of the table top, it is necessary to drill 4 holes whose depth is approximately 100 mm.

- The legs of the table predetermine the ax until their diameter becomes 45 mm.

- Take a heavy hammer and take the legs into the holes. You must understand that after you score legs, it will be impossible to pull them out. Therefore, immediately follow their correct location.

- Fasten the legs by means of long screws.

- Turn the table and with the help of the level, check the borders of the legs of the legs, then cut them out.

- Check how much the table is stable. To do this, simply turn it over it.

In order for the legs subsequently, they should be rotated, they must be treated with a special means. If you plan to place a table on the street, then the worktop must be covered with a special varnish against moisture.

If you want to save your money and eventually get furniture that will suit you in all respects, then boldly begin to make it independently manufacturing and assembling. We wish you good luck in all your endeavors.